GIDINGS&LEWIS 503-15275-27 输入输出模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 503 - 15275 - 27 输入输出模块介绍

产品概述

产品应用领域

英文资料:

Introduction to GIDINGS&LEWIS 503-15275-27 Input/Output Modules

Product Overview

In the industrial automation system, the GIDINGS&LEWIS 503-15275-27 input/output module is like a bridge connecting the controller and peripheral devices, shouldering the key mission of signal interaction. As an industrial grade I/O module, it is widely used in CNC machine tools, automated production lines, and various other industrial control systems. This module has diverse functions, supporting digital input, digital output, and partial analog signal processing, and can accurately meet the signal requirements of different types of devices. During CNC machining, it can convert the machining instructions issued by the controller into digital signals, control the spindle speed, feed axis movement and other actions, and receive analog signals feedback from tool sensors to monitor the tool status in real time; In automated production lines, equipment operation status information is collected through digital input functions, and the start stop and operation of assembly machinery, detection equipment, etc. are controlled through digital output. At the design level, it incorporates considerations of high reliability and anti-interference ability. From hardware materials to circuit layout, they have been carefully optimized to ensure stable and accurate signal transmission in complex industrial environments, such as factory workshops with strong electromagnetic interference and processing sites with frequent vibrations, laying a solid foundation for the stable operation of industrial control systems.

Product application areas

Numerical Control Machine Tool: In the field of numerical control machine tools, the 503-15275-27 input/output module is the core component for achieving precise machining control. It is tightly connected to the CNC controller on one end and receives various instructions from the programming system, such as machining path planning, tool selection, and other information; The other end is connected to the spindle, feed axis, cutting tools, and numerous sensors of the machine tool. By precise control of the spindle, its speed and direction can be adjusted to meet the processing needs of different materials and processes; Accurately control the displacement of the feed axis to achieve micrometer level machining accuracy. When processing complex components, the module receives signals from tool sensors, determines the degree of tool wear, and promptly notifies the system for tool replacement to ensure processing quality. Support automatic tool changing function, control the tool changing mechanism through digital signals, achieve fast and accurate tool switching, and improve machining efficiency. By utilizing the signal input from the workpiece positioning sensor, the workpiece is accurately positioned before processing, laying the foundation for high-precision machining. Real time monitoring of machining status, such as simulated signals of cutting force, vibration, etc., and feedback to the controller for timely adjustment of machining parameters to avoid machining errors or equipment failures.

Automated production line: In an automated production line, this input-output module plays a key role in process coordination and automation operations. It provides signal support for the conveyor system, controls the start stop and speed of the conveyor belt according to the production rhythm, and ensures the orderly flow of materials. In the electronic product assembly production line, the assembly machinery is controlled to accurately grasp and install components, and the movement sequence and force of the robotic arm are precisely controlled through digital output signals to achieve high-precision assembly.

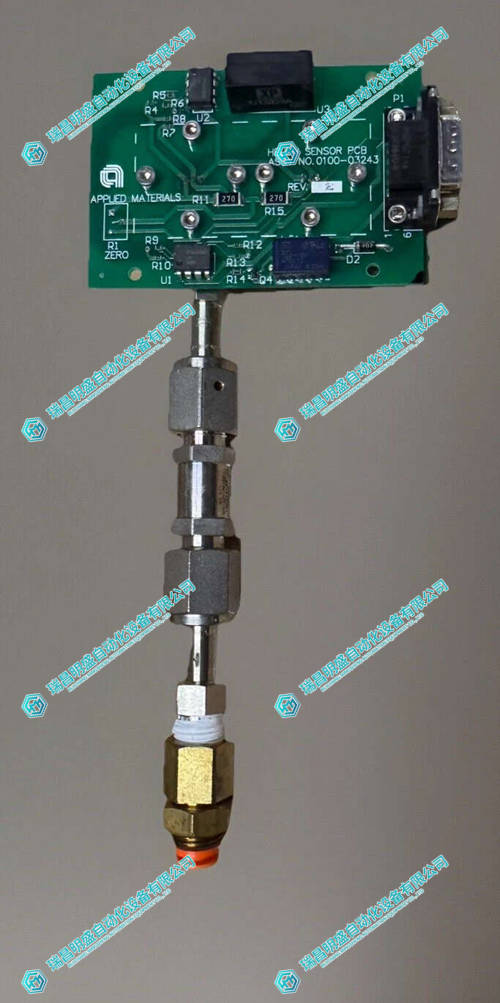

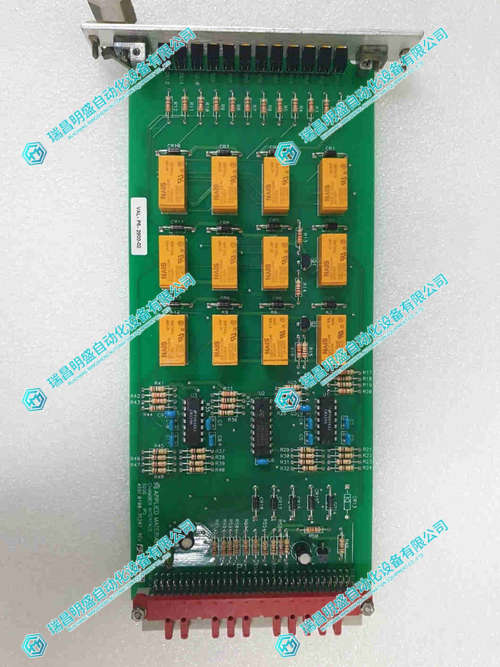

2.产 品 展 示

3.其他产品

4.其他英文产品

5SHY4045L0006 3BHB030310R0001 thyristor

Gasonics 853-4290-001 Load Lock Elevator

ATLAS COPCO PF4002-C-DN-HW Controller

| PC832-XYZ-T | 57330001-Y DSBB110A ABB | |

| PC832-XYZ-N | AMAT 0100-91040 | NFTP01 |

| PC832-XYZ-A | AMAT 0100-00120 | HESG332194R0001 70BK06A-E |

| PC832-111-N-4122-11 | AMAT 0100-09034 | HESG447440R0003 RS422/485 70BK03C-E |

| PC832-111-N | AMAT 0100-89004 | 57510001-AA DSCA114 ABB RS232C |

| PC832-102-N-4122-11 | AMAT 0100-35012 | 57350001-CU DSAV111 ABB |

| PC832-102-N | AMAT 0100-35126 | NTRO03 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218