GIDINGS&LEWIS 501-04308-00变频器控制板

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 501 - 04308 - 00 变频器控制板介绍

产品概述

产品特点

英文资料:

Introduction to GIDINGS&LEWIS 501-04308-00 Inverter Control Board

Product Overview

In the complex operation system of industrial automation and CNC machine tools, the GIDINGS&LEWIS 501-04308-00 frequency converter control board occupies a pivotal position and can be regarded as the core control unit. Its core task focuses on comprehensive and precise control of AC motors, including speed regulation, torque control, and direction switching. By finely tuning the frequency converter signal, it can drive the motor to operate efficiently and achieve precise motion control effects. When processing complex components on CNC machine tools, precise motor speed regulation is required to match different processing techniques, and this control board can demonstrate its capabilities; In an automated production line, multiple motors work together, and their precise control of motor torque and steering ensures the smooth operation of the production line. It attaches great importance to the security and stability of the system, integrating multiple protection mechanisms from hardware design to software algorithms, ensuring stable and reliable operation even in long-term and high-intensity industrial production environments, laying a solid foundation for the efficient and sustainable development of industrial production.

Product Features

High precision control: The 501-04308-00 frequency converter control board has excellent high-precision control performance and fully supports closed-loop control modes for motor speed, torque, and direction. In a closed-loop control system, it utilizes various sensors to capture real-time operational status data of the motor, such as speed sensors providing feedback on motor speed and torque sensors monitoring output torque, which are quickly transmitted back to the control board. The control board uses precise algorithms to quickly calculate and accurately adjust the output signal of the frequency converter based on the preset target value, thereby correcting the motor operation deviation and ensuring smooth and stable operation throughout the entire process. When precision milling is carried out on CNC machine tools, it is required that the spindle motor speed be stable within a very small error range. This control board can control the speed fluctuation to a very small degree through closed-loop control, ensuring stable cutting force of the tool and achieving micrometer level machining accuracy, meeting the strict requirements of high-end manufacturing industry for component machining accuracy.

Fast dynamic response: Faced with the frequent changes in motor load and the actual demand for fast start stop in industrial production, this control board demonstrates strong high-speed signal processing capabilities. When the load carried by the motor suddenly increases or decreases, such as when material handling equipment in an automated production line grabs and releases heavy objects, the load changes dramatically. The control board can sense this change in a very short time and quickly analyze and process it. With the internal high-speed computing chip and optimized control algorithm, the frequency and voltage output of the inverter can be quickly adjusted to enable the motor to adapt to load changes in a timely manner and maintain stable operation. In the scenario of rapid motor start stop, such as industrial robots frequently starting and stopping to perform handling tasks, it can achieve fast response, shorten motor start and stop time, improve production efficiency, reduce equipment lag or uncoordinated actions caused by slow response, and ensure efficient and smooth industrial production process.

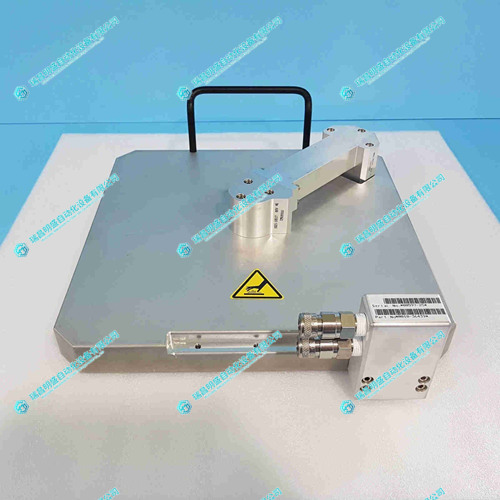

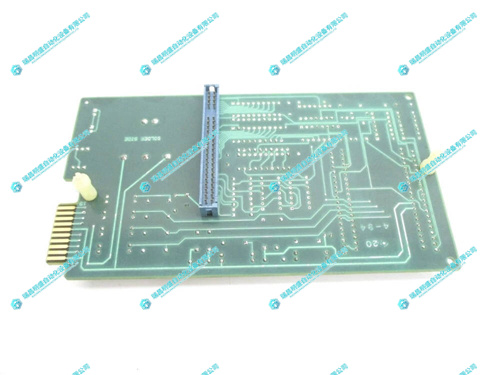

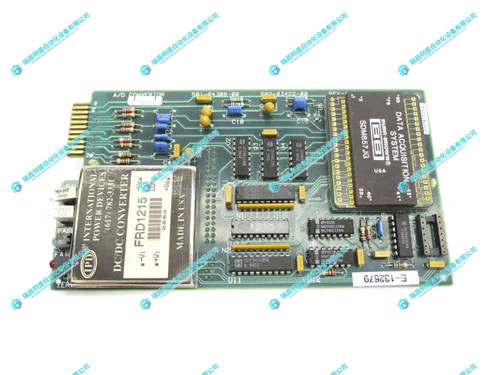

2.产 品 展 示

3.其他产品

4.其他英文产品

Atlas Copco PF3007-G-DN-HW Controller

Atlas Copco PF3007-C-HW Torque Controlle

Atlas Copco PF3007-G-DN-HW Controller

| K42HRLM-LNK-NS-00 | AMAT 0100-11066 | 57310001-CM DSCS131 ABB |

| K42HLLN-LNK-NS-01 | AMAT 0100-40044 | HESG446680R0001 70EA03A-E |

| K42HLLK-LNK-NS-00 | AMAT 0100-90855 | HEIE420696R0001 XP8670A |

| K42HLHN-LNK-NS-01 | AMAT 0100-01108 | HESG332204R0001 70PR05B-E |

| K42HLFK-LNK-NS-00 | AMAT 0100-09220 | INTKM01 |

| K42HCHM-LNK-NS-00 | AMAT 0100-91119 | INICT13A |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218