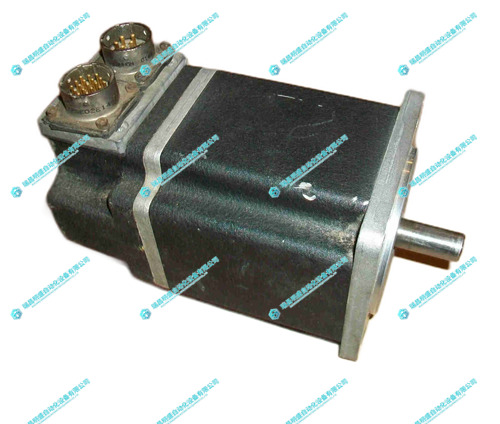

GIDINGS&LEWIS 401-30236-00无刷伺服电机

1.产 品 资 料 介 绍:

产品概述

产品特点

英文资料:

Product Overview

In the current accelerating process of industrial automation, GIDINGS&LEWIS 401-30236-00 brushless servo motor, as a high-performance industrial motor, is deeply integrated into key fields such as CNC machine tools, automated production lines, and robot systems, becoming the core driving force for promoting efficient industrial operation. It abandons the traditional mechanical commutation structure of brushed motors and adopts advanced brushless design, which brings many significant advantages. From the perspective of energy efficiency, the brushless structure greatly reduces energy loss, achieves efficient operation, and reduces the production energy consumption cost of enterprises; The low inertia characteristic enables the motor to respond extremely quickly, accurately responding to control signals in an instant, quickly starting, stopping, accelerating, and decelerating, meeting the demand for rapid equipment movement in complex industrial scenarios. In terms of stability and reliability, brushless design reduces mechanical wear and friction, lowers the probability of failure, enables long-term stable operation, and ensures the continuity of industrial production. With these outstanding performances, it can accurately achieve positioning and smooth motion control in various complex working conditions, providing a solid guarantee for high-precision and high-efficiency industrial production.

Product Features

High precision positioning: The 401-30236-00 brushless servo motor performs excellently in high-precision positioning, with the key being its close coordination with the encoder. Encoders are like the "eyes" of motors, capable of accurately detecting the position information of the motor rotor in real time and quickly feeding this information back to the control system. The control system accurately adjusts the operating status of the motor based on the feedback data from the encoder, achieving micrometer level position control accuracy. When machining precision components on CNC machine tools, such as milling aircraft engine blades, the motor needs to precisely control the tool position to achieve micrometer level machining accuracy. The motor, combined with a high-precision encoder, can control the tool positioning error within a very small range, ensuring accurate and error free blade contour machining. The repeated positioning accuracy is also excellent, no matter how many start stop and operation cycles are experienced, it can stably return to the preset position, ensuring the consistency of processing and the stability of product quality, meeting the strict requirements of high-end manufacturing industry for processing accuracy.

High efficiency and low maintenance: The brushless structure is the core advantage of this motor in achieving high efficiency and low maintenance. Traditional brushed motors consume a large amount of energy during operation due to mechanical friction between the brushes and the commutator, resulting in low energy efficiency. Frequent friction also causes severe wear on the brushes, requiring regular maintenance and replacement, increasing maintenance costs and downtime for the enterprise. The 401-30236-00 brushless servo motor adopts electronic commutation method, completely eliminating the mechanical friction component of brushes and commutators, greatly reducing energy loss and significantly improving motor efficiency. Compared with brushed motors of the same power, the efficiency can be increased by 15% -25%. At the same time, the brushless structure reduces the internal mechanical components of the motor, significantly reduces wear and failure sources, effectively extends the service life of the motor, and significantly reduces maintenance requirements. It can be applied to industrial scenarios that require extremely high continuous operation of equipment,

2.产 品 展 示

3.其他产品

4.其他英文产品

Atlas Copco PF3007-G-DN-HW Controller

Atlas Copco PF3007-C-HW Torque Controlle

KEBA E-3-ACU-10 D1673B CPU motherboard

| K33HLHJ-LNK-NS-00 | AMAT 0100-00146 | INSEM11 |

| K33HLFM-LNK-NS-00 | AMAT 0100-90251 | INICT01 |

| K33HCHJ-LNK-NS-00 | AMAT 0100-90702 | IMASI23 |

| K32HSFL-LNK-NS-02 | AMAT 0100-3527 | 3500/91-01-02-00 |

| K32HRLM-LNK-NS-00 | AMAT 0100-09306 | 135489-01 |

| K32HRLG-LNK-NS-00 | AMAT 0100-00175 | 84933-02 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218