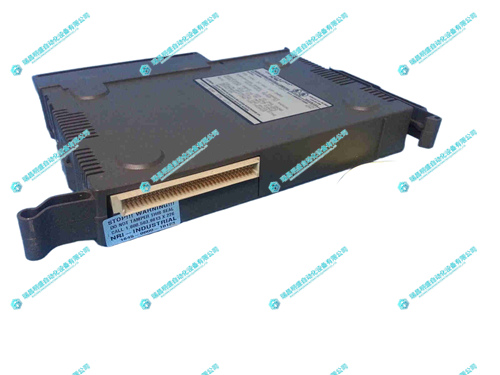

GIDINGS&LEWIS 502-03679-02编码器模块

1.产 品 资 料 介 绍:

产品基础特性

性能优势展现

英文资料:

The GIDDINGS&LEWIS 502-03679-02 encoder module plays a key role in the field of industrial automation, accurately converting various physical quantities into electrical signals that are easy for the system to process, laying the foundation for precise control and stable operation of equipment.

Product basic characteristics

Signal conversion mechanism: This encoder module utilizes advanced sensing technology to keenly perceive changes in physical quantities such as position and speed during device operation. For example, in the scenario of motor rotation, its built-in sensitive components can convert mechanical displacement into electrical pulse signals based on the rotation of the motor shaft. In the coordinate axis movement monitoring of CNC machine tools, the linear displacement of the coordinate axis can be converted into accurate electrical signal output in real time, providing feedback on the real-time operating status of the equipment for the control system.

Encoding type: Adopt [specific encoding type, such as incremental encoding or absolute encoding]. If incremental coding is used, the module will output a specific number of pulse signals for each displacement or rotation angle generated during equipment operation. By counting the number of pulses, the system can accurately calculate the operating distance or rotation angle of the equipment. In the monitoring of conveyor belt length on automated production lines, the running length of the conveyor belt can be accurately calculated by incremental coding. If it is an absolute encoding, the module will output a unique corresponding encoding value based on the different positions of the equipment. Whether the equipment is first started or suddenly powered off and restarted during operation, the accurate position of the equipment can be quickly determined. This is particularly important in aerospace component processing equipment that requires extremely high position accuracy.

Electrical parameter adaptability: It has good electrical parameter compatibility, a reasonable design of its working voltage range, and can adapt to various common industrial power sources. For example, it can work stably under a specific voltage range, such as 12V-24V DC power supply, reducing the difficulty of adaptation caused by power differences in different industrial environments. At the same time, its current carrying capacity has been carefully considered, and it can withstand the working current of [specific current value], ensuring stable operation under complex load conditions. In the scenario of driving large mechanical equipment with motor encoders, it can effectively cope with the high current impact at the moment of startup, ensuring the normal operation of the module itself and the connected equipment.

Performance advantage display

High resolution and high precision: The resolution is extremely high and can be precise to [specific resolution values, such as 1024 pulses per revolution or higher]. This means that extremely subtle positional changes can be captured during device operation. Taking precision grinding machines as an example, the encoder module can accurately monitor the rotation angle of the grinding wheel and the movement distance of the worktable during grinding, ensuring that the grinding accuracy reaches the micrometer level and effectively improving the surface quality and dimensional accuracy of the product. The high precision characteristic makes it an indispensable key component in industries that require strict precision, such as semiconductor manufacturing and medical device production. In the photolithography process of semiconductor chip manufacturing, the movement position of the lithography machine worktable can be precisely controlled to ensure the accuracy of the lithography pattern and improve the yield of chip manufacturing.

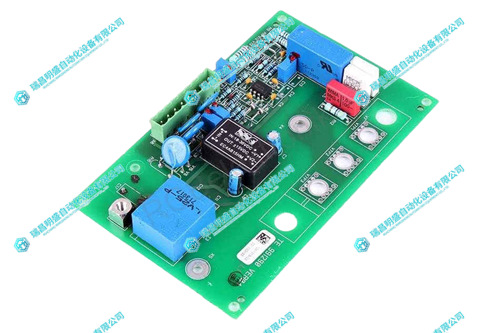

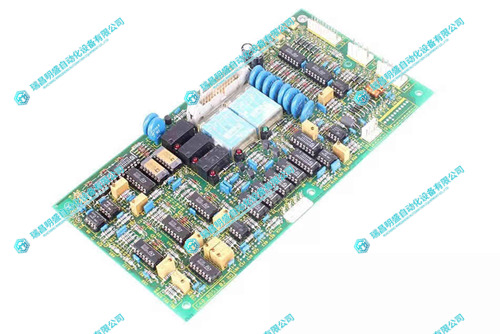

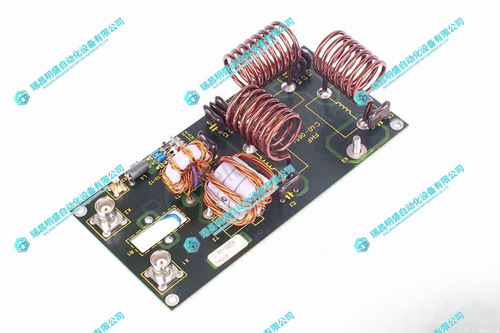

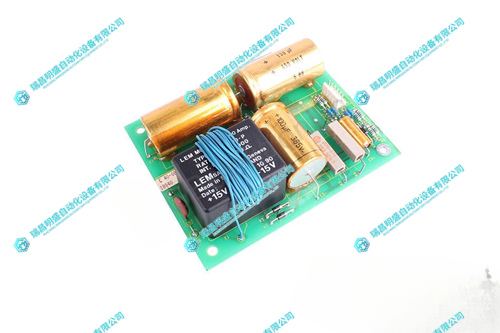

2.产 品 展 示

3.其他产品

4.其他英文产品

TEL Tokyo Electron 073-000123-1 Controller

Novellus Systems 03-056746-00 Controller

KLA Tencor 710-450320-00 Controller

| IC3600QOXA2 | 531X190SRCAGG1 | IC3600EPSS1 |

| IC3600QOXA1 | 531X190SRCAFG4 | IC3600EPSP1 |

| IC3600QIXB1 | 531X190SRCAFG3 | IC3600EPSN3D1B |

| IC3600QIXA1 | 531X190SRCAFG1 | IC3600EPSN3 |

| IC3600PVZA1 | 531X189LTBAKG1 | IC3600EPSM1E1B |

| IC3600PTJA4A | 531X189LTBAJG1 | IC3600EPSM1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218