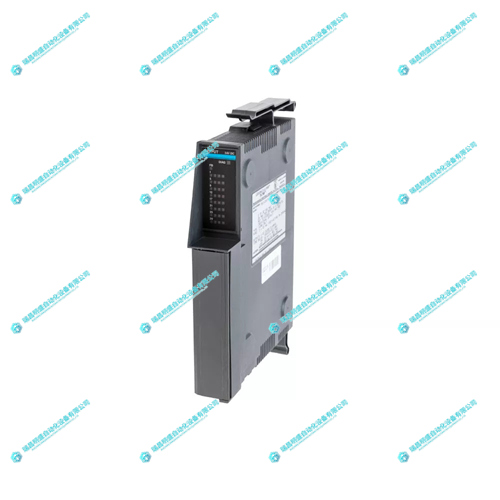

GIDINGS&LEWIS 502-03674-20 CPU模块

1.产 品 资 料 介 绍:

产品概述

性能优势展现

英文资料:

Product Overview

GIDINGS&LEWIS 502-03674-20 CPU module, as the core control unit in the field of industrial automation, is designed to cope with complex and harsh industrial environments. Its core position is reflected in the precise control of logical operations, data processing, and collaborative operation between equipment in the entire industrial system. Whether it is precise planning of tool paths during CNC machining or orderly connection of various processes in automated production lines, this CPU module plays a key role as the "brain" to ensure efficient, stable, and precise operation of equipment.

Performance advantage display

Powerful computational processing capability: Equipped with a high-performance industrial grade processor, it has high-speed data processing and logical computing capabilities. Capable of processing a large number of input signals from sensors, operation instructions, and other devices in a very short period of time, and quickly generating corresponding control instruction outputs. For example, when processing complex parts on a multi axis CNC machine tool, this module can process real-time position feedback signals of each coordinate axis, accurately calculate the tool's motion trajectory, ensure machining accuracy reaches the micrometer level, and meet the high precision requirements of industries such as aerospace and precision mold manufacturing. Its computing speed and processing power have significant advantages compared to similar products, greatly improving production efficiency and product quality.

Rich storage resources: With sufficient built-in RAM, it can quickly store and read temporary data during operation, ensuring smooth system operation. Simultaneously equipped with non-volatile storage, it is used to reliably store program code and important data, ensuring that critical information is not lost even after the system is powered off. This feature enables the device to quickly recover to its pre power outage working state after restarting, reducing production interruption time caused by unexpected power outages and improving production continuity and stability. During the long-term operation of automated production lines, a large amount of production data and equipment operating parameters can be safely stored, facilitating subsequent data analysis and equipment maintenance.

Diversified and efficient interface design: equipped with multiple industrial standard bus interfaces, such as Ethernet interface, which can achieve high-speed data communication with the upper computer, other intelligent devices or network systems, facilitating remote monitoring, program updates and real-time transmission of production data; The RS-232/RS-485 interface is suitable for connecting with some traditional devices or sensors to achieve bidirectional data exchange. In addition, it also has rich I/O expansion interfaces, which can easily connect various input and output modules and flexibly expand system functions according to actual production needs. In industrial automation production lines, through these interfaces, the CPU module can collaborate with various devices such as logic controllers, encoders, servo drives, solenoid valves, etc., to build a complete and efficient automation control system.

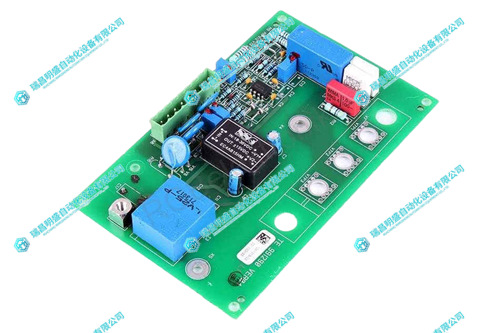

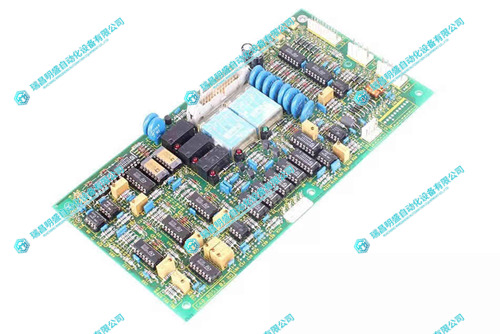

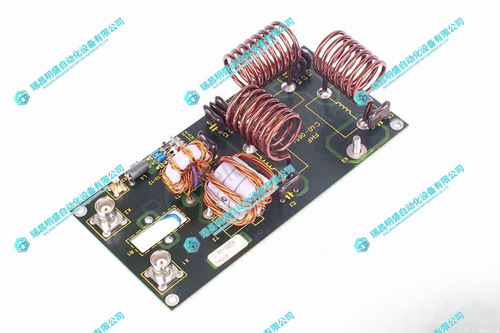

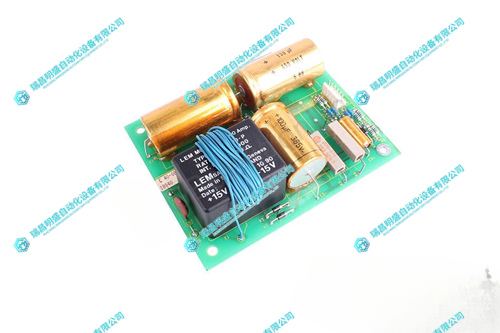

2.产 品 展 示

3.其他产品

4.其他英文产品

KLA Tencor 710-450320-00 Controller

KLA Tencor 710-611529-000 Control Board

EATON PL9-C10-2-DC Circuit Breaker

| IC3600LTDA1 | 531X1860CPSAHG1 | IC3600EPSH1 |

| IC3600LSSA1 | 531X185CPTAMG1 | IC3600EPSE2 |

| IC3600LSRM1 | 531X185CPTALG1 | IC3600EPSE1D1B |

| IC3600LSRD1 | 531X185CPTAKG1 | IC3600EPSD1C1B |

| IC3600LSRB1A | 531X184IPTAFG1 | IC3600EPSC1B |

| IC3600LSRB1 | 531X184IPTAEG1 | IC3600EPSC1 |

| IC3600LSRA1 | 531X184IPTADG1 | IC3600EPSB1C |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218