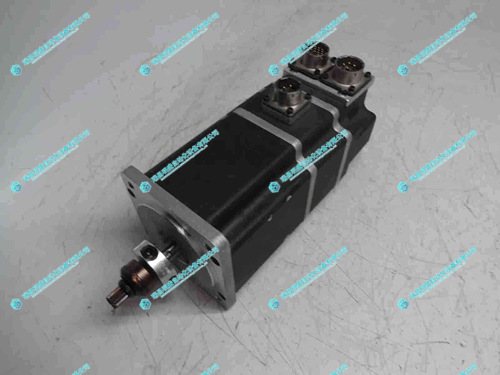

GIDINGS&LEWIS NSM3406无刷伺服电机

1.产 品 资 料 介 绍:

产品基础概述

核心构造与工作原理

性能参数亮点

英文资料:

Product Overview

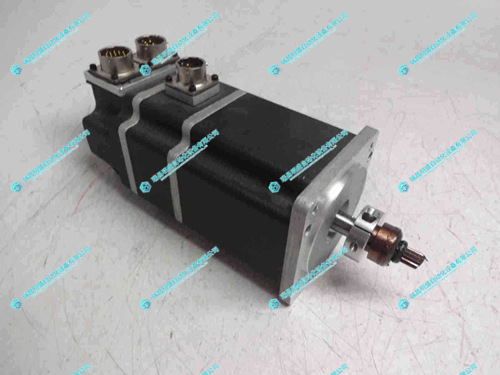

GIDDINGS&LEWIS NSM3406 brushless servo motor, as an important power output device in industrial automation processes, plays a key role in many industrial scenarios with its excellent performance and reliable quality. It can efficiently and accurately convert electrical signals into mechanical motion by working in conjunction with servo drives, achieving precise control of equipment speed, position, and torque, injecting strong power into the efficient and stable operation of various industrial equipment.

Core Structure and Working Principle

Construction design: NSM3406 adopts an advanced permanent magnet synchronous motor structure, mainly composed of two parts: stator and rotor. The stator is made of stacked silicon steel sheets and wound with three-phase windings, which can generate a rotating magnetic field when powered on. The rotor is made of high-performance permanent magnet materials, and its constant magnetic field interacts with the rotating magnetic field of the stator to drive the rotor to achieve efficient rotation. The bearings used inside the motor have been specially designed and strictly selected, with the characteristics of low friction and high load capacity. This allows the rotor to maintain smooth operation even when rotating at high speeds, effectively reducing mechanical vibration and wear, greatly extending the service life of the motor. The motor casing is made of high-strength and corrosion-resistant industrial grade materials, which have good protective performance and can effectively resist the erosion of dust, moisture, and other harmful substances in industrial environments, ensuring reliable operation of the motor even under harsh working conditions.

Working principle: Based on the principle of electromagnetic induction, when the servo driver inputs three-phase AC power that varies according to a specific law to the stator winding of NSM3406, the stator winding will generate a rotating magnetic field, and the speed of this magnetic field is proportional to the power frequency, which is called synchronous speed. Due to the interaction between the magnetic field of the rotor permanent magnet and the rotating magnetic field of the stator, electromagnetic torque is generated, which drives the rotor to rotate synchronously with the rotating magnetic field of the stator. During operation, precise control of motor speed, position, and torque can be achieved by precisely adjusting the frequency, amplitude, and phase of the input current with the help of servo drives. For example, when motor acceleration is required, the driver increases the input current frequency to accelerate the stator rotating magnetic field, thereby driving the rotor to accelerate rotation; When precise control of the motor position is required, the driver adjusts the input current in real time based on the position information provided by feedback devices (such as encoders) to ensure that the motor accurately stops at the designated position.

Performance parameter highlights

Rated power and torque output: With a wide range of power specifications to choose from, the rated power range ranges from [specific minimum rated power] to [specific maximum rated power], which can fully meet the needs of industrial equipment with different loads. In terms of torque output, it performs excellently, with a rated torque of up to [specific rated torque value], and can output higher peak torque in a short period of time, usually about [X] times the rated torque, which is sufficient to easily cope with sudden high torque requirements such as equipment startup, acceleration, and overcoming heavy loads, ensuring that the motor can start smoothly and run stably, even when operating at full load, it can still maintain good performance and stability.

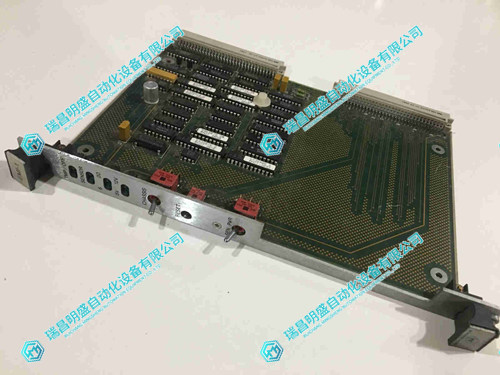

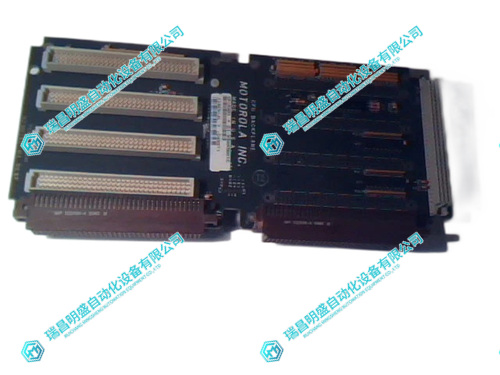

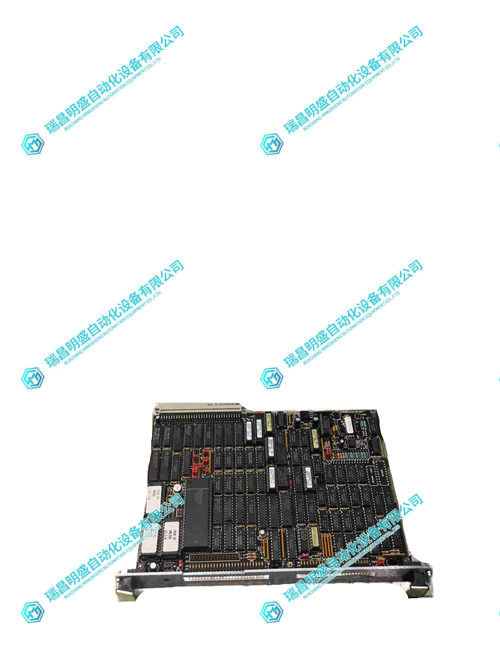

2.产 品 展 示

3.其他产品

Bachmann IPC1412 FRE CM1G1 1G CF8G XPE通信处理器

4.其他英文产品

GE IS210BPPBH2BMD Controller Module

KOLLMORGEN CP310250 PRD-P310250Z-55 serv

| IC3600KMVB2 | 531X137TRGACG1 | IC3600AFGA1D1B |

| IC3600KMRE2 | 531X137TRGAAG1 | IC3600AFGA1D1 |

| IC3600KMRD9 | 531X136TBGAAG1 | IC3600AFGA1C1 |

| IC3600KMRD2 | 531X135PRGBBG1 | IC3600AFGA1B |

| IC3600KMRC5 | 531X135PRGAYM2 | IC3600AFGA1 |

| IC3600KMRC2 | 531X135PRGAWM2 | IC3600ADNA1 |

| IC3600KMRB5 | 531X135PRGATM2 | IC3600ADN1A |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218