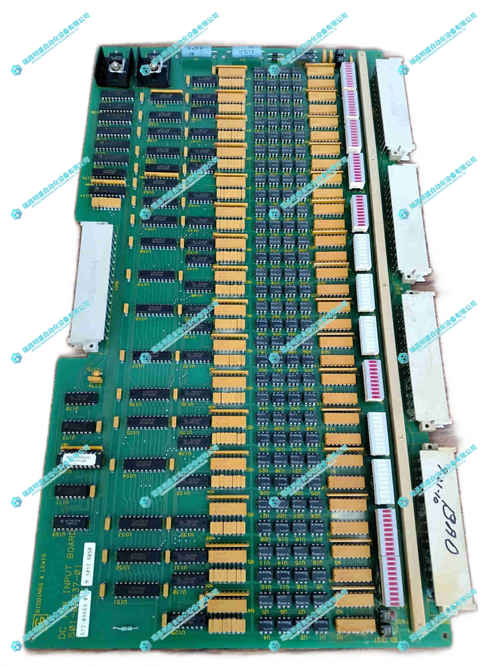

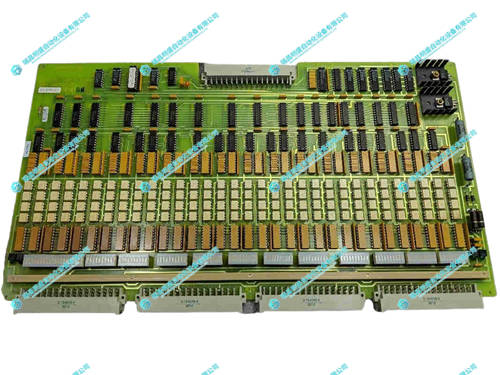

GIDINGS&LEWIS 572-03553-01直流输入板

1.产 品 资 料 介 绍:

产品概述

核心功能特性

英文资料:

Product Overview

GIDINGS&LEWIS 572-03553-01 DC input board, as an important part of industrial control systems, focuses on the access and processing of DC signals. In complex industrial production environments, a large number of devices generate various DC signals, which carry key information such as equipment operating status and process parameters. This DC input board is like a precise signal "gatekeeper", responsible for accurately introducing the DC signals transmitted from external devices into the control system, while preprocessing the signals to provide a reliable data basis for subsequent control decisions, ensuring the stable operation and precise control of the entire industrial control system.

Core functional characteristics

Multi channel DC signal access: It has multiple DC signal input channels and can simultaneously connect multiple devices that generate DC signals, such as sensors, switches, transmitters, etc. Taking the industrial automation production line as an example, the DC signals generated by temperature sensors, pressure sensors, and various position switches on the line can be connected to the control system through different channels of the input board, realizing the collection of multi-dimensional data in the production process and providing rich data sources for comprehensively grasping the production status.

Signal conditioning and conversion: Equipped with advanced signal conditioning circuits, it can filter, amplify, and level convert input DC signals. When the weak DC signal output by the sensor enters the input board, the signal conditioning circuit will amplify it, enhance the signal strength, and facilitate subsequent accurate measurement and analysis; At the same time, noise interference in the signal is removed through filtering operations to ensure the purity of the signal and avoid signal misjudgment caused by noise. In addition, for DC signals with different level standards, the input board can perform level conversion to meet the interface requirements of the control system, achieving seamless signal integration and stable transmission.

Isolation protection function: To enhance the reliability and safety of the system, the 572-03553-01 DC input board adopts electrical isolation technology. During signal transmission, the circuits on the input and output sides are electrically isolated to effectively block the impact of external interference signals on the control system and prevent equipment failures caused by electrical interference. For example, in industrial sites with complex electromagnetic environments, electromagnetic interference generated by the operation of a large number of electrical equipment may enter the DC signal line. The isolation protection function of the input board can resist these interferences, ensure the accurate transmission of DC signals, and protect other components of the control system from damage caused by abnormal situations such as high voltage and overcurrent, thereby improving the stability and anti-interference ability of the entire industrial control system.

Status monitoring and feedback: Built in status monitoring circuit can monitor the signal status of each input channel in real time. Feedback the working status of the channel to the operator or control system through indicator lights or communication interfaces. When a signal loss or abnormal voltage occurs in a certain channel, the status monitoring circuit will immediately capture the abnormality and issue an alarm through corresponding means to remind the staff to promptly troubleshoot the problem.

2.产 品 展 示

3.其他产品

4.其他英文产品

CI871AK01 3BSE092693R1 interface module

VE5010 Logic Controller Module

KJ3222X1-BA1 Analog Input Module

| DVC 310 | 531X122PCNAHG1 | PCS124PS-200 |

| DS200SIOBH1A | 531X122PCNAEG1 | NTAI02 |

| DS200DCFBG1BLC | 531X122PCNACG1 | NLIS01 |

| DS200DCFBG1B | 531X121PCRALG1 | NSSM01 |

| DS200DCFBG1A | 531X121PCRAKG1 | PCS105PS-400 |

| DO3201-A-V001 | CACR-SR05AC2ER | NMF01 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218