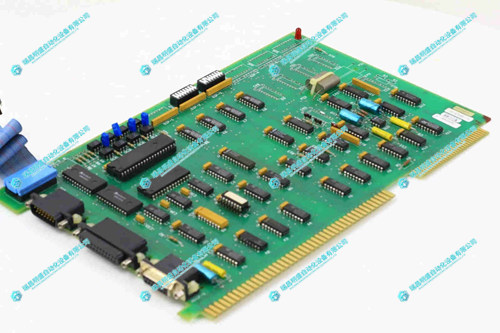

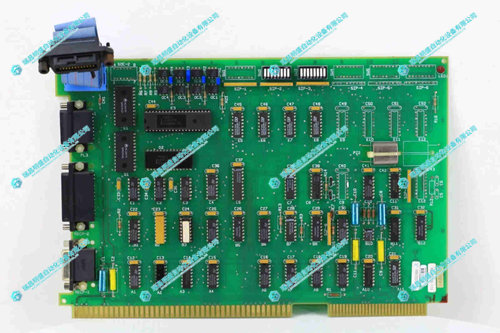

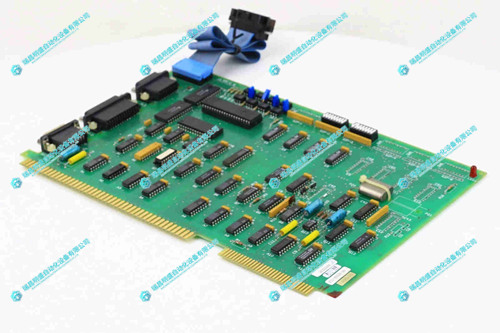

GIDINGS&LEWIS 411-80029-86控制器模块组件

1.产 品 资 料 介 绍:

产品概述

核心功能特性

英文资料:

Product Overview

The GIDINGS&LEWIS 411-80029-86 controller module component, as a core component in industrial automation control systems, shoulders a critical mission. It is like the "command center" of the entire system, precisely regulating the operation of various equipment to ensure the smooth and efficient industrial production process. This component integrates advanced technology and exquisite craftsmanship, designed specifically for complex industrial environments, aiming to provide reliable and powerful control capabilities for CNC machine tools, automated production lines, robot systems, etc., promoting industrial production to a new level of higher precision and efficiency.

Core functional characteristics

Signal processing and logical operations: With excellent signal processing capabilities, it can quickly and accurately receive input signals from various sensors, switches, and communication interfaces. Whether it is analog signals such as temperature, pressure, and position that reflect the operating status of the equipment, or digital signals such as operating instructions issued by the operator, they can all be sensitively captured by it. After receiving the signal, the high-performance processor integrated inside the module will quickly perform logical operations and data processing on these signals based on preset programs and complex algorithms. For example, in industrial production, when sensors detect an abnormal increase in equipment temperature, the controller module can quickly analyze the signal, determine whether it exceeds the normal threshold range, and combine it with other relevant signals such as equipment running time, load conditions, etc. to perform comprehensive calculations, providing a solid data foundation for subsequent control decisions.

Instruction execution and device driving: After completing signal processing and logic operations, the 411-80029-86 controller module will generate precise control instructions based on the operation results, and accurately transmit these instructions to actuators such as motors, valves, relays, etc. to drive them to perform corresponding actions. Taking motor control as an example, the module will send control signals to the motor driver based on the calculated parameters such as voltage, current, and rotation direction required by the motor, accurately regulating the speed and direction of the motor, achieving precise motion control of the equipment, ensuring the coordinated operation of various equipment in the industrial production process, and meeting the strict requirements of different production processes for equipment operation accuracy and speed.

Status monitoring and feedback regulation: It has real-time status monitoring function, constantly monitoring the operating status of various devices in the system, and continuously monitoring key parameters such as voltage, current, temperature, etc. Once abnormal fluctuations in parameters are detected, the module can immediately trigger protection mechanisms, such as taking power-off measures to prevent equipment damage due to overcurrent or overvoltage, or activating the alarm system to notify operators to handle faults in a timely manner. At the same time, the control strategy can be adjusted according to the actual situation, and feedback adjustments can be made to ensure stable operation of the system under complex working conditions. In an automated production line, when a device experiences a brief overload causing an increase in current, the controller module can quickly reduce the operating power of the device or adjust the working rhythm of related equipment to avoid serious problems such as lagging or even shutdown of the production line, ensuring the continuity and stability of the production process.

2.产 品 展 示

3.其他产品

4.其他英文产品

AMAT 0190-66253 Communication Module

CI860K01 3BSE032444R1 power module

CI871AK01 3BSE092693R1 interface module

| EP3758-5151-7-56BC-CU | 531X124MSDAJG1 | 63-0050-02 |

| EP3752-5215-7-56BC-CU | 531X124MSDAHG2 | EPC-26-0-0 |

| EP3648-4952-7-56BC-CU | 531X124MSDAHG1 | EPC-16 |

| EP3644-5214-7-56BC-CU | 531X124MSDAGG2 | 8MC12 |

| EP3640-1436-7-56BC-CU | 531X124MSDAGG1 | 330730-040-00-00 |

| EP3632-1435-7-56BC-CU | 531X124MSDADG1 | IC3600TPAE1B1C |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218