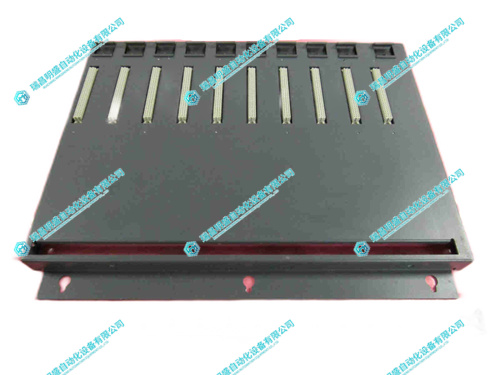

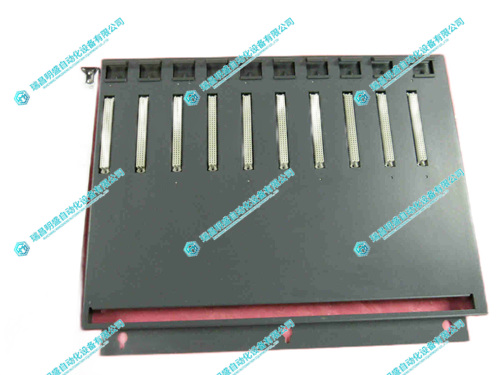

GIDINGS&LEWIS 503-18010-01 插槽系统机架

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 503 - 18010 - 01 插槽系统机架介绍

一、功能架构与作用

二、硬件设计特点

英文资料:

GIDINGS&LEWIS 503-18010-01 Slot System Rack Introduction

In the construction of industrial automation systems, slot system racks serve as the core carrier and integration platform, playing a key supporting role in the stable operation and functional expansion of the system. The GIDINGS&LEWIS 503-18010-01 slot system rack, with its excellent design and reliable performance, has become an ideal choice in many industrial scenarios.

1、 Functional Architecture and Function

Module Integration Center: The 503-18010-01 rack is like the "nerve center" of industrial control systems, providing a stable and orderly installation platform for various functional modules. Taking industrial automation production lines as an example, various key components such as control modules, input/output (I/O) modules, communication modules, etc. can be accurately installed in rack slots. These modules achieve efficient data exchange and collaborative work through the electrical connection system inside the rack, thus building a complete industrial automation control system to ensure the precise operation of the production line, such as precise control of material conveying speed, equipment start stop timing, etc.

Electrical connection and signal transmission: The rack is designed with a precise conductive rail system inside, similar to the "blood vessels" of the human body, providing stable power supply and high-speed, reliable signal transmission channels for each module. When the control module sends command signals, they can be quickly and accurately transmitted to the corresponding execution module through the conductive rails inside the rack, ensuring the timeliness and accuracy of the system response. For example, in the machining process of CNC machine tools, control instructions are quickly transmitted from the control module to the motor drive module through the frame conductive rail, achieving precise tool positioning and ensuring machining accuracy.

System scalability support: This rack has excellent scalability, and its multiple slots are designed to reserve sufficient space for future functional upgrades and scale expansion of the system. With the expansion of enterprise production scale or the improvement of technology, if new functional modules need to be added, such as more channel I/O modules to meet the signal acquisition and control needs of new equipment, or advanced communication modules to achieve more efficient data exchange, simply insert the new modules into the idle slots of the rack and perform simple configuration and debugging to easily expand and upgrade system functions, reducing the secondary development cost and time cost of the enterprise.

2、 Hardware design features

Durable and sturdy structural material: To adapt to complex and demanding industrial environments, the 503-18010-01 rack is made of high-strength steel to create the main structure, which has excellent impact and vibration resistance performance. In industrial sites, equipment often faces mechanical vibrations, external collisions, and other situations. With its sturdy structure, this rack can effectively protect internal modules from damage and ensure long-term stable operation of the system. For example, in industrial scenarios with high vibration such as mining and heavy machinery manufacturing, the normal operation of internal modules can be reliably guaranteed, reducing equipment failures and downtime caused by mechanical damage.

2.产 品 展 示

3.其他产品

ABB REG670 1MRK002826-AC 安全系统组件

4.其他英文产品

Radisys EPC-3307 processor board

| 6ES5895-3SF55 | CACR-SR15BE | 68-0059-12 |

| 6ES5895-0BS22 | CACR-180-PD1VDS03 | 061-01183-0031 |

| 6ES58941MA040UD3 | CACR-SR05SB1BFY187 | 504802-008 |

| 6ES58940MA040UG6 | CACR-SR-20SB1BFY118 | UIMC-III-1 |

| 6ES58640MA040UG4 | CACR-SR15BE12FY8 | 46088203 |

| 6ES58487DA040UG4 | CACR-UP50AABY45 | 067-10100-0006 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218