GIDINGS&LEWIS 502-03280-00 通信模块

1.产 品 资 料 介 绍:

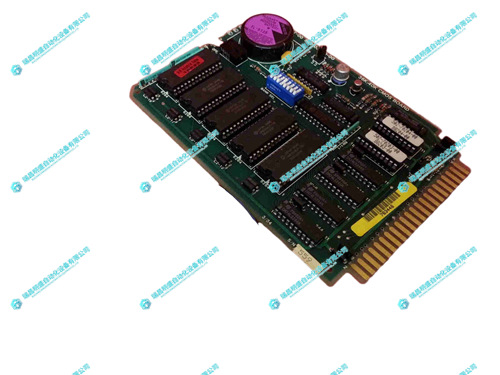

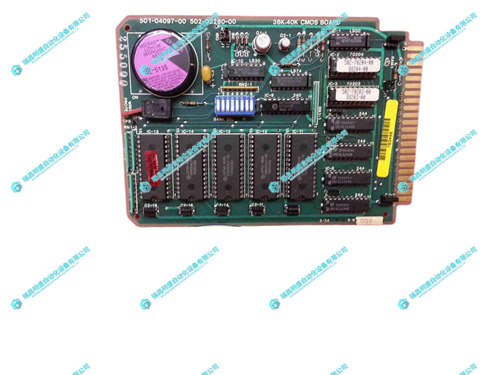

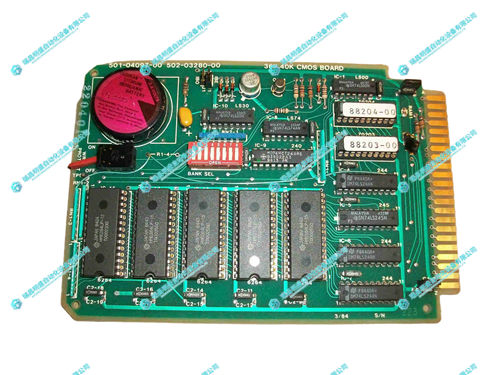

GIDDINGS&LEWIS 502-03280-00 通信模块介绍

一、产品功能架构

英文资料:

Introduction to GIDDINGS&LEWIS 502-03280-00 Communication Module

In industrial automation control systems, efficient communication between devices is the foundation for achieving collaborative work, precise control, and data exchange. The GIDDINGS&LEWIS 502-03280-00 communication module, as a key component in industrial network architecture, has built a bridge for information exchange for various industrial equipment with its excellent communication capabilities and reliable performance.

1、 Product functional architecture

Multi protocol communication support: The 502-03280-00 communication module has strong compatibility and can support multiple industrial communication protocols. For example, the common Modbus protocol, whether it is Modbus RTU (used for serial communication, widely used in short distance, low-speed data transmission scenarios, such as connecting small sensors and actuators on site) or Modbus TCP (an Ethernet based communication protocol, suitable for high-speed, large data transmission, commonly used in workshop level equipment networking), this module can be easily adapted. In addition, it also supports the PROFIBUS-DP protocol, which enables fast and reliable data exchange between master and slave stations in automated production lines, tightly connecting PLCs with various on-site devices to ensure efficient collaboration throughout the entire production process. This multi protocol support capability enables the module to be flexibly applied in complex industrial networks composed of different brands and types of devices, greatly improving the convenience of system integration.

Data transmission and conversion: The module bears the important responsibility of data transmission and format conversion. In industrial sites, various types of equipment generate data in different formats, and the 502-03280-00 communication module can parse and repackage data from different devices. For example, it can convert analog data collected by sensors (such as continuously changing electrical signals output by temperature and pressure sensors, after analog-to-digital conversion) into digital format, package it according to communication protocol requirements, and then transmit it to the upper computer or other control devices through the network. At the same time, for the control instructions issued by the upper computer, the module can accurately convert them into signal formats recognizable by the equipment, achieving precise communication of control instructions and ensuring consistency between equipment operation and system control objectives.

Network connection and topology construction: This communication module provides rich network interfaces, including Ethernet interfaces and serial ports (such as RS-232, RS-485 interfaces). The Ethernet interface supports high-speed data transmission, making it easy to achieve remote monitoring and control of devices. The devices are connected to the factory network through Ethernet cables, and technicians can view the device's operating status and adjust parameters in real time through the upper computer software in the office. The RS-232 interface is suitable for point-to-point communication scenarios and is commonly used to connect debugging devices or communicate with peripheral devices that do not require high communication speed. The RS-485 interface has stronger anti-interference ability and longer transmission distance, which can support multi node connections and facilitate the construction of distributed industrial network topologies.

2.产 品 展 示

3.其他产品

4.其他英文产品

Kollmorgen 6SM37M-6000 servo motor

Radisys ATCA-PP81 controller module

AMAT 0190-24282 encoder module

| 5410-008 | H2-2022-1100 | IMMCF03 |

| 5410-006 | SSIV-18-R | IMNPM01 |

| 5410-003 | STD0002 | INBIM02 |

| 5410-002 | HA42B6-B212 | IMFBS01 |

| 5410 | HG101A6 | IMPTM01 |

| 5345 | PCC14-115VAC | INCT01 |

| 5330 | 531X102CCHAFM2 | INIIT03 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218