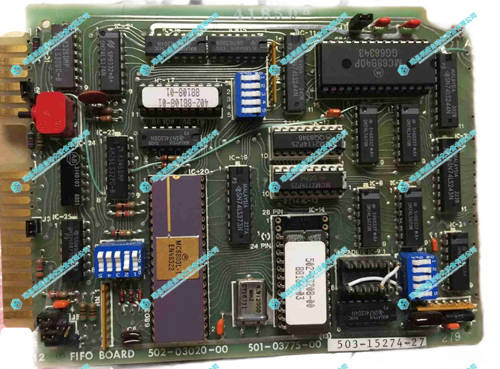

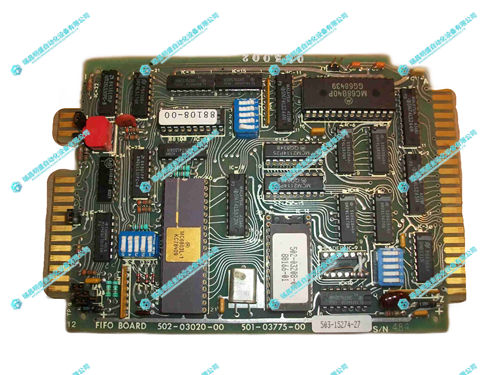

GIDINGS&LEWIS 503-15274-27 控制器模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 503-15274-27 控制器模块介绍

一、产品概述

二、典型应用领域

英文资料:

Introduction to GIDINGS&LEWIS 503-15274-27 Controller Module

In industrial automation control systems, the controller module is the "brain" that commands the operation of the entire system, undertaking the core responsibilities of signal processing, logical judgment, and instruction issuance. The GIDINGS&LEWIS 503-15274-27 controller module, with its powerful processing capabilities and wide adaptability, has become a key control unit in various industrial scenarios.

1、 Product Overview

The 503-15274-27 controller module is the core control component of the Giddings&Lewis system, designed specifically for precise control of industrial equipment, CNC machine tools, and automated production lines. It can centrally receive and process signals from various input and output modules, and achieve logical control and process management of devices by executing preset control programs. As the "nerve center" of the system, this module is not only responsible for coordinating the collaborative operation of various sub modules, but also undertakes the important task of internal and external communication management, ensuring the efficiency of instruction transmission and the accuracy of data exchange, providing solid guarantees for the stable operation of industrial systems.

2、 Typical application areas

CNC machine tool system: In CNC machine tools, this controller module is the "command center" for high-precision machining. It precisely controls the speed of the machine tool spindle, the movement trajectory of the feed axis, and the switching action of the tool. By analyzing the machining code, it converts complex geometric shapes into specific mechanical motion instructions. For example, in precision part machining, the module can adjust the feed rate and cutting depth in real time based on input parameters, and achieve closed-loop control with position feedback signals to ensure machining accuracy reaches the micrometer level, meeting the machining needs of industries such as aerospace and automotive manufacturing for high-precision parts.

Automated production line: The efficient operation of an automated production line relies on precise process control. The 503-15274-27 controller module is responsible for parsing the production process logic, coordinating the start and stop of conveying equipment, the timing of assembly equipment actions, and sensor signal feedback in this scenario. For example, on an electronic product assembly line, modules can control the speed of the conveyor belt based on material detection signals, synchronously trigger the grasping and placing actions of the robotic arm, and achieve full process automation from part loading to finished product production, greatly improving production efficiency and reducing manual intervention.

PLC system control: As the logic control core of the PLC system, this module can quickly process various input signals, including switch status, sensor data (such as temperature and pressure), and position information feedback from encoders. It then outputs control signals to actuators (such as solenoid valves and relays) or drive modules through preset logic operations. In packaging machinery, it can trigger packaging actions based on material arrival signals, while monitoring production through counters. When the preset value is reached, it automatically stops, achieving intelligent control of the production process.

2.产 品 展 示

3.其他产品

4.其他英文产品

RadiSys 61-0475-12 Axis Control Module

RADISYS 97-9536-20 Ethernet Port Module

Kollmorgen 6SM37M-6000 servo motor

| 6ES5721-0CC00 | CACR-IRA5A5A5F | 061-01666-0010 |

| 6ES5721-0BF00 | CACR-SR44SZ1SDY231 | EMC-BP8-EMC-PS |

| 6ES5721-0BB00 | CACR-SR15BB1CSY8 | 61-0367-37 |

| 6ES5714-3CF00 | CACR-SR05BA1AM | 148472-006 |

| 6ES5714-3CB00 | CACR-SR15SZ1SSY228 | C2SBI-RSYS-JD1 |

| 6ES5712-8BF00 | CACR-HR10UB-Y9 | EMC-BP12 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218