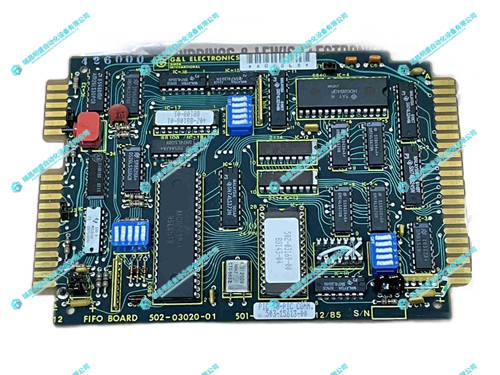

GIDINGS&LEWIS 503-15613-00存储板

1.产 品 资 料 介 绍:

一、产品概述

二、典型应用领域

英文资料:

1、 Product Overview

The 503-15613-00 storage board is an important component of the Giddings&Lewis system, designed specifically for data storage and management in control or numerical control systems. It provides solid hardware support for control modules, PLC (Programmable Logic Controller) or CNC (Computer Numerical Control) systems with its reliable data storage capability, for properly storing key information such as operating programs, set parameters, and historical data. Its modular design concept not only facilitates installation and integration in the system, but also flexibly expands storage capacity according to actual needs to adapt to industrial applications of different scales and complexities.

2、 Typical application areas

CNC machine tool system: During the operation of CNC machine tools, the 503-15613-00 storage board plays a crucial role. It is responsible for storing machine tool programs, which precisely guide every action of the machine tool, from tool positioning to cutting depth, ensuring the accuracy and efficiency of the machining process. Meanwhile, process parameters such as cutting speed and feed rate are also stored, which directly affect the machining quality and efficiency. In addition, tool information, including tool type, wear condition, and detailed processing records such as processing time and number of processed parts, can be found in this storage board. By efficiently storing and quickly accessing these data, precise control of CNC machine tools has been achieved, greatly improving the accuracy and efficiency of machining.

Automated production line control: The smooth operation of automated production lines relies on precise process settings and real-time equipment status monitoring. The 503-15613-00 storage board stores the process settings of the production line here, detailing the operation sequence and time nodes of each link to ensure the orderly transportation and processing of materials. Operation instructions are also stored, controlling the start, stop, and running speed of various devices. At the same time, equipment status records such as motor temperature and conveyor belt operation status can also be stored in real-time. This not only supports the system to quickly recover to its previous stable operating state during startup, but also provides rich data basis for subsequent equipment maintenance and optimization, ensuring the efficient and stable operation of the automated production line.

PLC system data storage: For a PLC system, the logic program is its core, which determines how the system makes logical judgments based on input signals and outputs corresponding control signals. The 503-15613-00 storage board reliably stores these logic programs, as well as control parameters such as various threshold settings, timer parameters, etc. In addition, device status data, such as feedback information from sensors and the working status of actuators, are also fully saved. After the system is powered off or restarted, the storage board can ensure the integrity of these data, allowing the PLC system to quickly recover to its previous working state, avoiding system failures and production interruptions caused by data loss.

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA DSQC100 connector backplane

ASEA 2668 184-447 Communication Module

RadiSys 61-0475-12 Axis Control Module

| 6ES5734-5BD20 | CACR-UP130AABY18 | 061-00719-0027 |

| 6ES5734-1BD20 | CACR-SR03BB1AM | C52711-014R |

| 6ES5731-1BD20 | CACR-PR44BC3CSY165C | 60-0219-00 |

| 6ES5728-1BD00 | CACR-SR44SF1AFBY30 | EPC-26 |

| 6ES5727-1CD20 | CACR-SR44BY1SDY48E | 60-0147-02 |

| 6ES5727-0AA11 | CACR-SR10BE12G-E | 067-03351-0000 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218