GIDINGS&LEWIS 401-34320-00伺服电机

1.产 品 资 料 介 绍:

Giddings & Lewis 401-34320-00 伺服电机介绍

产品概述

技术参数(典型值,基于同系列机型)

应用场景

英文资料:

Introduction to Giddings&Lewis 401-34320-00 Servo Motor

Product Overview

The Giddings&Lewis 401-34320-00 servo motor belongs to the FSM series of medium inertia brushless AC servo motors. It has high-speed response characteristics and can respond to control signals in a very short time, quickly adjust speed and steering, and meet the needs of rapid start stop and dynamic operation of the equipment. At the same time, the motor has high-precision control capability, which can accurately control the output torque, speed, and position of the motor, providing stable and accurate power output for various industrial applications. With these advantages, in the field of CNC machine tools, it can ensure high precision and high speed of machine tool processing; In industrial automation production lines, ensuring efficient and stable operation of each link is an indispensable power component in industrial production.

Technical parameters (typical values, based on models of the same series)

Maximum speed: up to about 4000 RPM, higher speeds can enable the equipment to complete more work cycles per unit time, improving production efficiency. For example, in some high-speed cutting CNC machine tools, high-speed servo motors can drive the tool to rotate quickly, achieving efficient material removal.

Continuous output power: about 2.5 kW, this power level can meet the power requirements for continuous operation of various industrial equipment, whether it is driving the operation of large mechanical components or providing power for various actuators in automated production lines, it can play a stable role.

Rated torque: about 6.9 Nm. The rated torque determines the stable torsional force that the motor can output under normal working conditions. This value enables the motor to drive equipment with a certain load inertia to operate smoothly, ensuring the stability and reliability of equipment operation.

Rated current: about 12 A RMS. The current required for the motor to operate under rated conditions is relatively stable, which helps to ensure the stable design and operation of the equipment power supply system, and ensures the coordinated operation of the motor with other electrical equipment.

Working frequency range: between 0-267 Hz. The wide working frequency range allows the motor to adapt to different working scenarios and control requirements. The operating frequency can be flexibly adjusted according to actual working conditions to achieve precise control of motor speed and other parameters.

Application scenarios

CNC machine tool: As a spindle motor, it can provide powerful and stable cutting power for the machine tool, ensuring high-precision cutting under different materials and cutting processes, and ensuring the quality and dimensional accuracy of the machined surface. When acting as a feed axis motor, it can accurately control the movement of the machine coordinate axis, achieve fast and accurate positioning, and enable the tool to process according to the preset path, meeting the processing requirements of complex parts.

Automated production line: In the packaging process, the operating speed and position of packaging equipment can be precisely controlled to achieve accurate packaging of products, improve packaging efficiency and quality; In the assembly process, it can provide stable driving for assembly equipment such as robotic arms, ensure accurate grasping and installation of components, and guarantee the efficiency and synchronization of the assembly process;

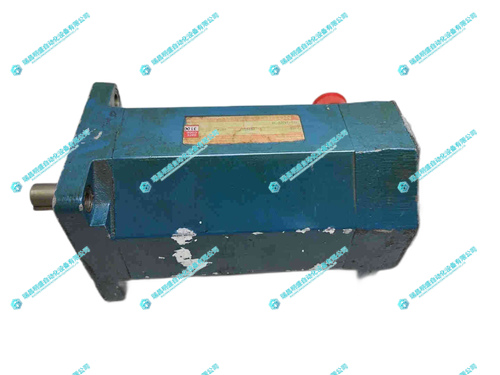

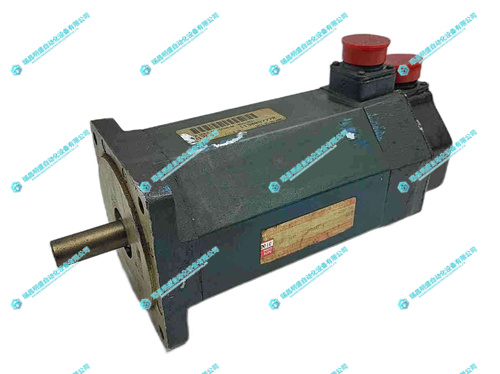

2.产 品 展 示

3.其他产品

ABB PU512V2 3BUR001401R1数字输出模块

ABB PU515A 3BSE032401R1数字输入模块

KOLLMORGEN S21260-SRS驱动器

4.其他英文产品

HIMA K9202 Fan components

HIMA K9202B Fan components

HIMA K9203 Fan components

| AMAT 0100-09110 | TP-1278-1 | VM600 RPS6U 200-582-500-0 |

| AMAT 0100-71220 | TP-1385-2 | 43518 |

| AMAT 0100-71224 | TP-8026-2 | F8650X 984865065 |

| AMAT 0100-35177 | TP-8041-3 | PCD235A101 3BHE032025R01 |

| AMAT 0100-A0491 | TP-8047-2 | 04240FD11234A |

| AMAT 0100-00409 | TP-8048-2 | VM600 MPC4 200-510-071-11 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218