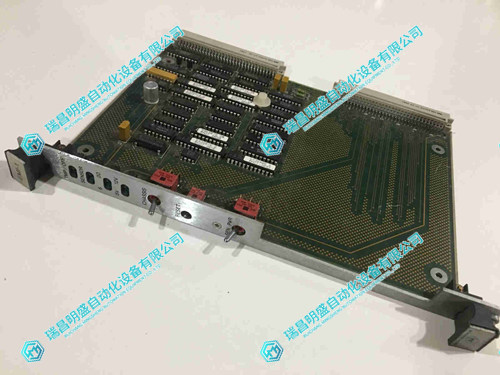

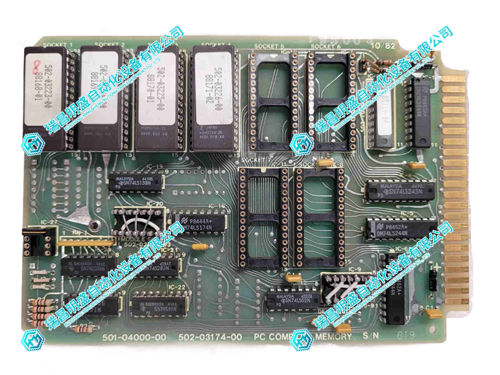

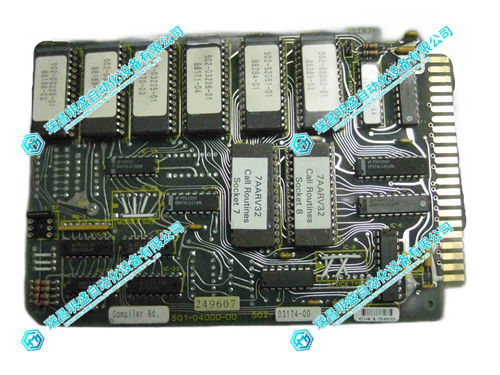

GIDINGS&LEWIS 501-04000-00伺服控制板

1.产 品 资 料 介 绍:

Giddings & Lewis 501 - 04000 - 00 伺服控制板介绍

产品概述

产品特点

英文资料:

Introduction to Giddings&Lewis 501-04000-00 Servo Control Board

Product Overview

In the precision industrial control system system built by Giddings&Lewis, the 501-04000-00 servo control board is like a "power conductor", controlling the key rhythm of servo motor operation. It is located in the core link of industrial equipment automation operation, with one end tightly connected to the controller, accurately receiving various complex instructions; On the other end, it efficiently drives the servo motor, generating precise pulses or analog signals to achieve all-round precise control of the servo motor's positioning, speed, and torque. Whether it is the strict requirements for tool positioning and spindle speed in the machining process of CNC machine tools, or the fine operation of material handling and component assembly actions in industrial automation equipment, this servo control board is a key execution module to ensure stable and efficient operation of equipment, providing strong support for high-precision and high-efficiency industrial production.

Product Features

High precision motion control: With advanced control algorithms and hardware design, the 501-04000-00 servo control board demonstrates excellent precision in speed, position, and torque control. In the field of CNC machine tools, it can control the positioning accuracy of the motor within a very small error range, ensuring that the tool can move accurately along the preset trajectory when machining parts, and produce complex components that meet high-precision standards. In automation equipment, the motor torque can be accurately adjusted to ensure stable operation and efficient action switching when handling objects of different weights, fully meeting the demanding requirements of industrial production for motion accuracy.

Quick response: Equipped with a high-speed signal processing chip, it can parse and process control instructions at an extremely fast speed. When receiving start-up, braking, or dynamic adjustment instructions from the controller, the servo control board can instantly convert the instructions into corresponding driving signals and transmit them to the servo motor, causing the motor to quickly respond. In automated production lines, the material handling rhythm is compact, and this control board can ensure fast motor start stop, achieving efficient material transportation and precise positioning, greatly improving production efficiency. In precision machining scenarios, the fast response characteristic ensures that the motor can adjust its speed and position in a timely manner according to changes in the machining process, further improving machining accuracy.

Industrial grade reliability: fully considering the complexity and strictness of the industrial production environment, from component selection to overall structural design, all follow industrial grade standards. select high-temperature resistant components to ensure stable operation of the internal circuit of the control board in high-temperature workshop environments, without problems such as signal drift or component damage caused by high temperatures. Anti vibration design effectively resists continuous mechanical vibrations generated during the operation of industrial equipment, ensuring firm internal solder joints and stable circuit connections. The use of long-life components, after long-term aging testing and practical operation verification, supports the continuous operation of control boards for a long time, providing a solid guarantee for the continuity of industrial production.

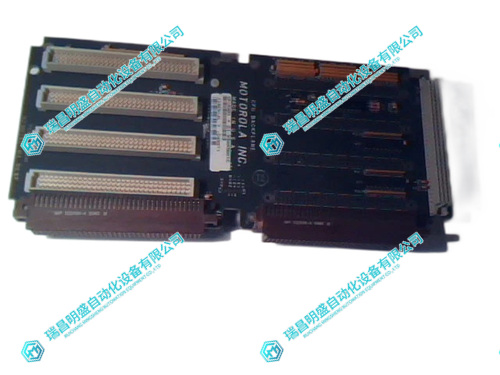

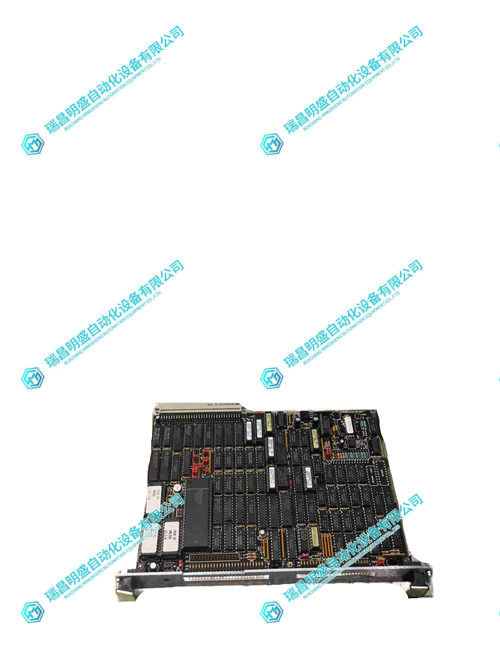

2.产 品 展 示

3.其他产品

GE WESDAC D20ME数字模拟转换器

LAETUS LLS570-05高速数字模块

NI SCXI-1000数据采集模块

4.其他英文产品

PM861K01 3BSE018105R1 Control module

PTQ-PDPMV1 Ethernet module

EMERSON 1000554 module card

| AMAT 0190-08498 | AMAT 0190-77197 | AMAT 0190-09511 |

| AMAT 0190-77116 | AMAT 0190-77220 | AMAT 0190-09526 |

| AMAT 0190-22907 | AMAT 0190-77221 | AMAT 0190-09533 |

| AMAT 0190-27084 | AMAT 0190-77226 | AMAT 0190-09546 |

| AMAT 0190-22543 | AMAT 0190-77273 | AMAT 0190-09547 |

| AMAT 0040-39892 | AMAT 0190-77284 | AMAT 0190-09552 |

| AMAT 0190-28554 | AMAT 0190-77294 | AMAT 0190-09563 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218