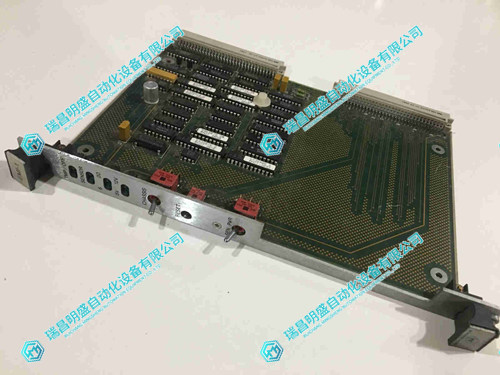

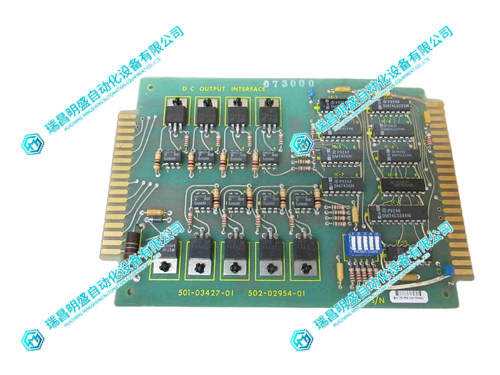

GIDINGS&LEWIS 501-03427-01伺服控制板

1.产 品 资 料 介 绍:

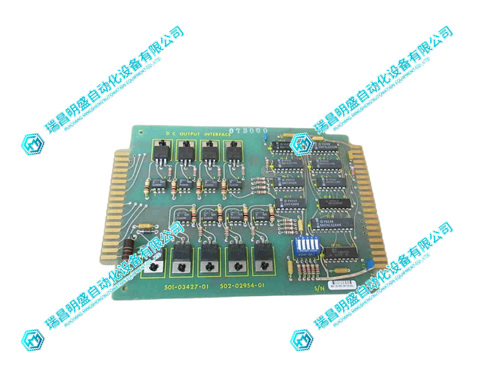

Giddings & Lewis 501 - 03427 - 01 伺服控制板介绍

产品概述

产品特点

英文资料:

Introduction to Giddings&Lewis 501-03427-01 Servo Control Board

Product Overview

In the industrial automation system carefully constructed by Giddings&Lewis, the 501-03427-01 servo control board occupies an important position as the core execution module. It is like a "smart bridge" connecting the controller and servo motor, with one end accurately receiving various command signals from the controller, and the other end relying on powerful computing and signal processing capabilities to generate extremely accurate control outputs, thereby driving the servo motor to achieve precise control of position, speed, and torque. This servo control board plays a crucial role in ensuring the smooth progress of industrial production and meeting product quality standards, whether in CNC machining processes with almost stringent precision requirements or in automated equipment systems that pursue efficient and precise operation.

Product Features

High precision motion control: The 501-03427-01 servo control board relies on advanced control algorithms and precise hardware architecture to demonstrate excellent performance in speed, position, and torque control dimensions. In the actual machining scenario of CNC machine tools, it can control the speed fluctuation of servo motors within a very small range, ensuring the stability of tool cutting process, thereby achieving high-precision surface finish machining. For position control, its accuracy can be precise to the micrometer level, enabling the machine tool to strictly follow the preset program and accurately move when processing complex component contours, meeting high-precision processing requirements such as precision molds and aviation components. In terms of torque control, the motor torque can be adjusted in real-time and accurately according to factors such as the hardness of the processed material and cutting process requirements, ensuring the efficiency and stability of the machining process.

Quick response: The built-in high-speed signal processing chip and optimized circuit design enable the control board to parse and execute control instructions at an extremely fast speed. When the controller issues a start command, the control board can transmit the drive signal to the servo motor within milliseconds, achieving fast motor start, reducing equipment waiting time, and improving production efficiency. In scenarios where rapid motor braking or dynamic adjustment of operating status is required, such as emergency stop and steering operations of material handling equipment in automated production lines, this control board can also respond quickly, ensuring precise and timely motor actions, effectively improving motion control accuracy, and avoiding equipment collisions, material drops, and other problems caused by response delays.

Industrial grade reliability: Fully considering the complexity and strictness of industrial production environments, high-quality electronic components with high temperature resistance and vibration resistance are strictly selected in component selection. These components have undergone long-term high-temperature aging testing and vibration simulation experiments, and can work stably in high-temperature workshops and industrial scenarios with frequent equipment vibrations. The overall structure of the control board adopts a reinforced design, which can effectively resist external forces such as mechanical vibration and impact in industrial environments, ensuring stable internal circuit connections and signal transmission. .

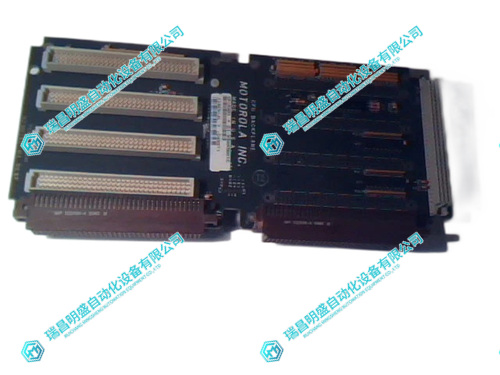

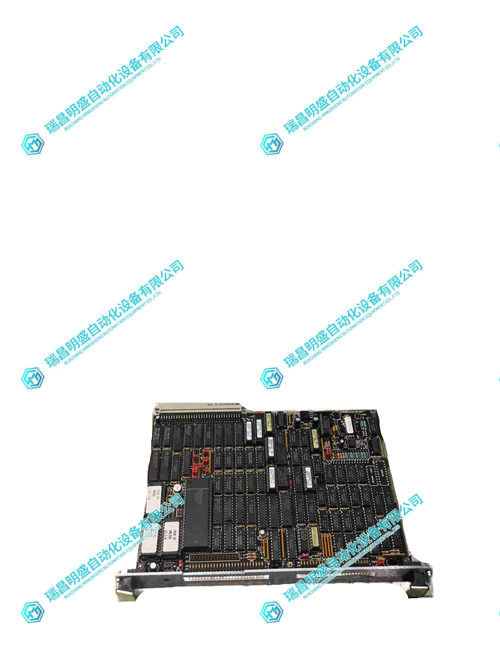

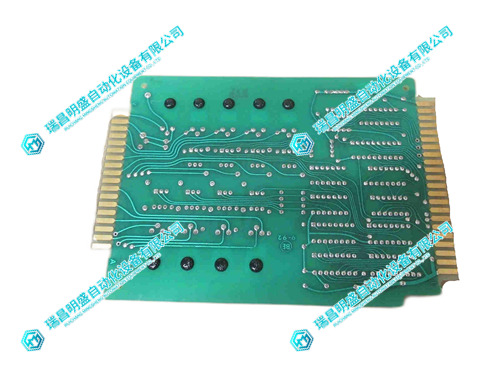

2.产 品 展 示

3.其他产品

LAETUS LLS570-05高速数字模块

NI SCXI-1000数据采集模块

NI SCXI-1125高精度模拟输入模块

4.其他英文产品

EMERSON 1000554 module card

WOODWARD 5501-470 Servo speed governor

7ML52020EA0 Ultrasonic level meter

| AMAT 0190-02850 | AMAT 0190-77395 | AMAT 0190-09760 |

| AMAT 0190-43719 | AMAT 0190-77438 | AMAT 0190-09776 |

| AMAT 0190-36233 | AMAT 0190-77499 | AMAT 0190-09789 |

| AMAT 0190-07312 | AMAT 0190-77521 | AMAT 0190-09791 |

| AMAT 0190-12164 | AMAT 0190-77526 | AMAT 0190-09961 |

| AMAT 0190-00003 | AMAT 0190-79952 | AMAT 0190-10017 |

| AMAT 0190-16250 | AMAT 0190-80057 | AMAT 0190-10025 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218