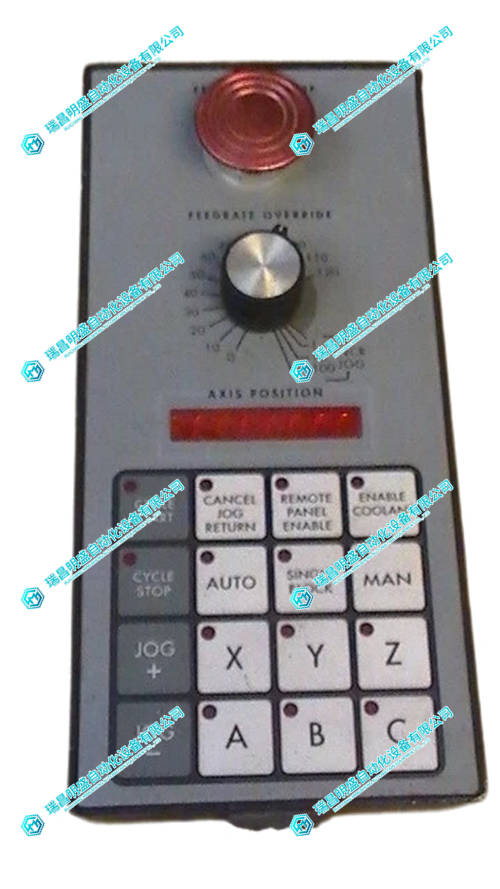

GIDINGS&LEWIS M.1018.3035悬挂控制

1.产 品 资 料 介 绍:

产品应用领域

英文资料:

Product application areas

CNC machine tool suspension system: In the field of CNC machine tools, the M.1018.3035 suspension control module plays a key role. Taking a milling machine as an example, when milling complex contours, the tool needs to move accurately in multiple directions. This module can precisely control the tool suspension device to achieve smooth up, down, and lateral movements, controlling the tool path error at the micrometer level, greatly improving machining accuracy, ensuring that the machined workpiece surface is smooth, without obvious tool marks, and meeting the requirements of high-precision part machining. In the lathe, the suspension control of the worktable can keep the workpiece stable during rotating machining, reduce vibration, and improve the surface quality of the machining. During boring machine operation, the module assists in stabilizing the suspension of the boring bar, achieving high-precision boring and ensuring that the roundness, cylindricity, and other positional tolerances of the hole meet strict standards.

Industrial automation equipment: For automated production lines, this suspension control module is an important component to ensure efficient operation of the equipment. During the operation of the rack, it can adjust the suspension posture of the rack in real time to ensure that it remains horizontal when conveying materials and avoid material slipping. With the help of this module, the transfer platform can achieve high-speed and smooth start stop and positioning, improving material transfer efficiency. In the assembly unit, precise suspension control enables the assembly robot to accurately grasp and install components, improving assembly accuracy and speed, and meeting the high requirements of industrial automation production for equipment motion stability and accuracy.

Robots and robotic arms: The end effector or suspension mechanism of the robotic arm relies on the M.1018.3035 module for precise control. When industrial robots perform welding operations, the module coordinates multi axis movements to ensure that the welding gun at the end of the robotic arm can move accurately along the weld seam, while maintaining dynamic stability, making the welding quality stable and reliable, and the weld seam uniform and beautiful. In the task of transporting heavy objects, it ensures the safe and stable lifting of goods by the suspension mechanism, adjusts the suspension parameters in real time according to the load weight, prevents the mechanical arm from shaking, and improves the safety and efficiency of the operation.

Vibration reduction and steady-state control: Combined with suspension control modules, it can effectively be used for equipment vibration reduction, balance adjustment, and dynamic stability control. In high-speed mechanical equipment, such as high-speed punching machines, modules automatically adjust suspension parameters by monitoring equipment vibration in real time, counteract vibration energy, reduce equipment wear caused by vibration, and extend equipment service life. For precision machinery, such as optical lens grinding equipment, it can accurately adjust the balance, ensure that the equipment is always in a stable state during the processing, improve processing accuracy, and meet the industry's high demand for processing environment stability.

Experimental and R&D platform: This module has a wide range of applications in scientific research experiments or testing devices. In simulated suspension motion experiments, various complex suspension motion scenarios can be accurately reproduced, providing reliable data for studying the mechanical properties of objects under different suspension conditions. When testing power response, the excitation input of the suspension system can be precisely controlled to obtain accurate equipment power response data, helping researchers to gain a deeper understanding of equipment performance. In terms of verifying motion control strategies, it provides a practical platform for new control algorithms, evaluates the advantages and disadvantages of algorithms through actual operation effects, and promotes the continuous innovation and development of motion control technology.

2.产 品 展 示

3.其他产品

ABB 216NG63 HESG441635R1电源控制模块

ABB 216VC62A HESG324442R0013模块

ABB REG216框架模块

4.其他英文产品

AB91-1 HESG437479R1 HESG437899 Control module

IT94-3 HESG440310R2 HESG112699B Control module

ICS TRIPLEX T8231 Control system module

| AMAT 0190-03069 | AMAT 0190-30421 | AMAT 0190-23114 |

| AMAT 0190-03150 | AMAT 0190-30454 | AMAT 0190-23215 |

| AMAT 0190-03294 | AMAT 0190-30888 | AMAT 0190-23314 |

| AMAT 0190-03295 | AMAT 0190-31257 | AMAT 0190-23441 |

| AMAT 0190-03504 | AMAT 0190-31258 | AMAT 0190-23441 |

| AMAT 0190-03554 | AMAT 0190-31268 | AMAT 0190-23498 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218