GIDINGS&LEWIS 503-12119-00处理器

1.产 品 资 料 介 绍:

工业控制核心大脑 ——GIDDINGS&LEWIS 501-02983-02 控制器板

多元应用场景

英文资料:

Industrial Control Core Brain - GIDINGS&LEWIS 501-02983-02 Controller Board

In the process of modern industrial automation, the controller board serves as the "brain" of equipment operation, and its performance directly affects production efficiency and product quality. The GIDINGS&LEWIS 501-02983-02 controller board stands out among numerous industrial application scenarios due to its excellent design and outstanding performance.

Multiple application scenarios

In the field of CNC machine tools: For milling machines, the 501-02983-02 controller board accurately interprets programming instructions and converts them into precise control signals for tool paths and worktable movements. When milling complex surface contours, it coordinates the operation of various coordinate axis motors to ensure that the tool moves with micrometer level accuracy and produces high-precision components that meet design requirements. In lathe operation, it monitors and adjusts spindle speed, tool feed rate and other parameters in real time to ensure the stability of the turning process, resulting in extremely high dimensional accuracy and low surface roughness of the machined shaft parts. The boring machine uses this controller board to accurately control the axial feed and circular motion of the boring bar, achieving high-precision boring and ensuring that the shape and position tolerances of the holes meet strict standards, providing solid machining control support for the mechanical manufacturing industry.

Industrial automation production line: On the automated assembly line, this controller board becomes the key to coordinating the orderly operation of various workstation equipment. In the material conveying process, it precisely controls the start stop and speed of the conveyor motor according to the production rhythm, ensuring smooth and efficient transportation of materials to the next workstation. At the assembly station, it receives component position information feedback from sensors, quickly processes it, and sends action instructions to the assembly robot to guide the robotic arm to accurately grasp and assemble components, improving assembly accuracy and efficiency. At the testing station, the controller board integrates data from various testing equipment to determine whether the product quality is qualified, and marks and diverts non-conforming products to ensure the quality stability of the output products on the production line.

Robots and automation equipment: When applied to industrial robots, the 501-02983-02 controller board is responsible for collaborative control of multi axis motion. When the robot performs welding tasks, it precisely controls the rotation angle and speed of each joint motor of the robotic arm based on the preset welding trajectory, so that the welding gun can move steadily and accurately along the weld seam, ensuring uniform and beautiful welding quality. In the scenario of transporting heavy objects, the controller board adjusts the driving force and posture of each joint of the robot in real time based on the load weight and transportation path, ensuring a safe and smooth transportation process and avoiding the shaking or falling of heavy objects. For automated sorting equipment, it quickly identifies product information, commands sorting mechanisms to accurately classify products, and improves sorting efficiency and accuracy.

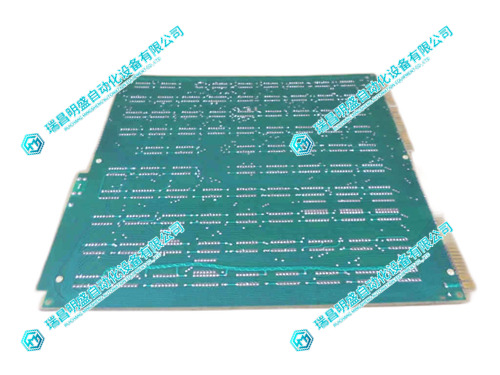

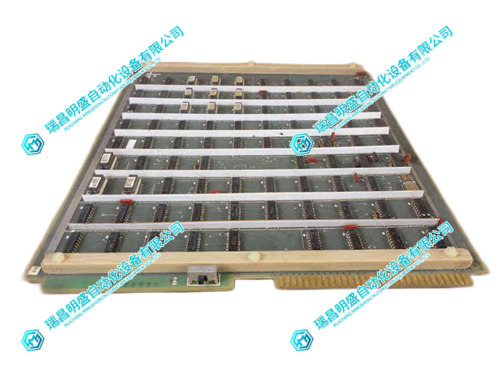

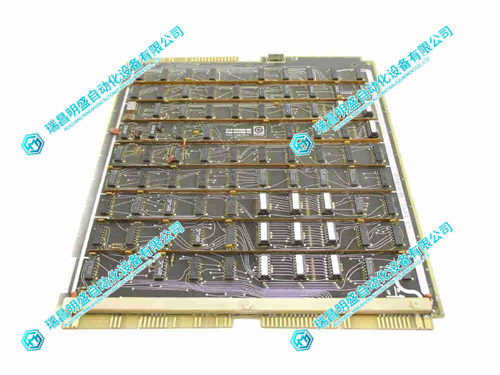

2.产 品 展 示

3.其他产品

TRICONEX EPI3382 通讯模块

TRICONEX DO3401 数字输出模块

TRICONEX DO2401 7400209-030 数字输出底座

4.其他英文产品

ICS TRIPLEX T8231 Control system module

1C31157G02 Input/output module

3BHB003688R0101 Power panel module

| AMAT 0190-04026 | AMAT 0190-32766 | AMAT 0190-23871 |

| AMAT 0190-04098 | AMAT 0190-32974 | AMAT 0190-23897 |

| AMAT 0190-04114 | AMAT 0190-33081 | AMAT 0190-23905 |

| AMAT 0190-04174 | AMAT 0190-33204 | AMAT 0190-23942 |

| AMAT 0190-04176 | AMAT 0190-33207 | AMAT 0190-23965 |

| AMAT 0190-04206 | AMAT 0190-33208 | AMAT 0190-24115 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218