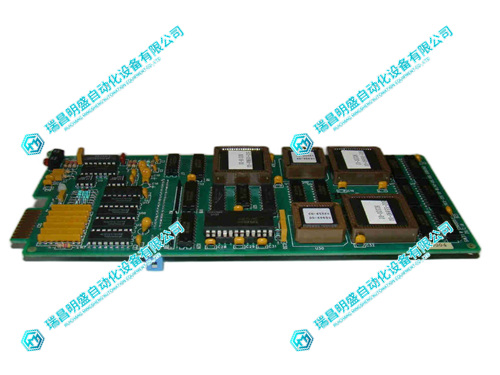

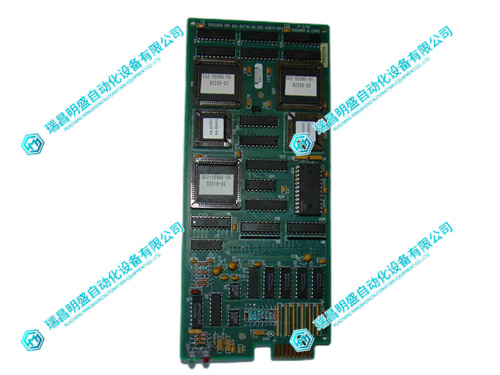

GIDINGS&LEWIS M.1008.0330 PCB编码板

1.产 品 资 料 介 绍:

GIDINGS&LEWIS M.1008.0330 PCB 编码板:工业自动化的精准定位专家

多元应用领域

英文资料:

GIDINGS&LEWIS M.1008.0330 PCB Encoding Board: Precise Positioning Expert for Industrial Automation

In the field of industrial automation, precise position detection and control are key to ensuring efficient and stable operation of equipment. GIDINGS&LEWIS M.1008.0330 PCB coding board, as a high-performance coding device, plays a crucial role in many key fields due to its excellent characteristics.

Diversified application areas

Position detection of CNC machine tools: In CNC systems such as lathes, milling machines, boring machines, etc., the M.1008.0330 coding board is an important guarantee for achieving high-precision machining. Taking milling machine processing of complex molds as an example, the encoding board accurately encodes and provides feedback on the rotation and linear position of the milling cutter shaft and worktable. By real-time monitoring of the relative position between the tool and the workpiece, the position information is accurately fed back to the control system, enabling the controller to adjust the tool path in a timely manner, ensuring that the machining accuracy reaches the micrometer level. The processed mold contour is precise and the surface is smooth, meeting the strict requirements of high-end manufacturing for precision machining.

Servo and stepper motor control: providing accurate position reference signals for servo motors or stepper motors is the core function of this encoder board in the field of motor control. In the automated assembly production line, the motor needs to accurately drive the robotic arm to complete the grasping and installation actions of the components. M. The 1008.0330 encoding board achieves closed-loop control of the motor by outputting precise position signals, allowing the motor to accurately adjust its speed and position according to instructions, driving the robotic arm to complete assembly tasks accurately and without errors, greatly improving assembly accuracy and efficiency.

Industrial automation equipment: The conveying devices, lifting platforms, or sorting equipment in automated production lines all rely on the M.1008.0330 coding board to achieve precise position detection and control. At the logistics sorting center, sorting equipment uses coding boards to accurately locate the position of goods and quickly sort them to different channels based on their information. The conveying device uses coding boards to ensure stable and accurate transportation of goods on the conveyor belt, avoiding cargo deviation or jamming, and ensuring smooth operation of the production line.

Robot control system: The multi axis coordination and path planning of industrial robots and robotic arms cannot be separated from accurate coding signals, and the M.1008.0330 coding board plays a key role in this. In the automotive welding workshop, when the robot performs welding tasks, the coding board provides precise coding signals for its multiple joint axes, allowing the robot's axes to move in coordination and move the welding gun accurately according to the preset path to complete complex welding work, ensuring stable and reliable welding quality.

Testing and R&D platform: In the experimental platform or testing system, the M.1008.0330 coding board provides reliable coding signal acquisition for researchers. For example, in the research of new material processing technology, it is necessary to accurately measure the motion parameters of the processing equipment. The encoding board can collect real-time equipment motion position signals, provide accurate data for motion analysis, assist researchers in verifying control strategies, accelerate the research and development process, and improve testing efficiency and data reliability.

2.产 品 展 示

3.其他产品

GE IC670ALG310模拟输入模块

REOTRON 567LH-DP24直流电源

SAGEMCOM 252720938AB控制模块

4.其他英文产品

P0916AA Terminal module

FORCE PMC234 robot card

1407-CGCMC module

| AMAT 0190-06071 | AMAT 0190-35243 | AMAT 0190-27579 |

| AMAT 0190-06073 | AMAT 0190-35250 | AMAT 0190-27580 |

| AMAT 0190-06098 | AMAT 0190-35254 | AMAT 0190-27661 |

| AMAT 0190-06120 | AMAT 0190-35255 | AMAT 0190-27707 |

| AMAT 0190-06182 | AMAT 0190-35259 | AMAT 0190-27818 |

| AMAT 0190-06212 | AMAT 0190-35278 | AMAT 0190-27886 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218