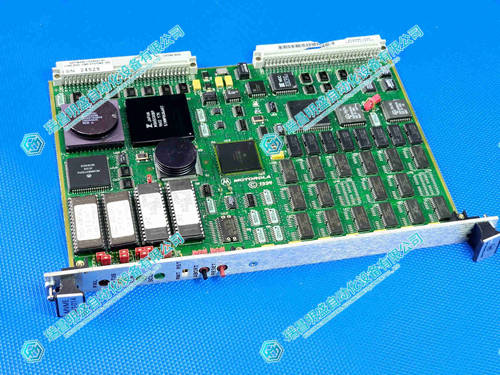

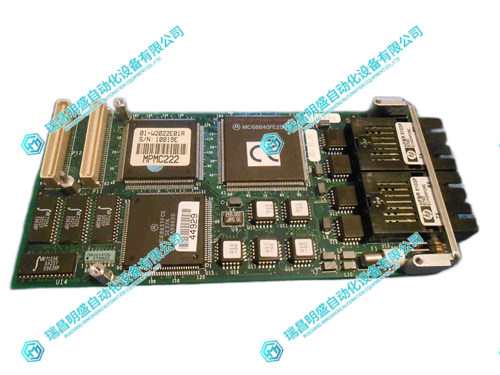

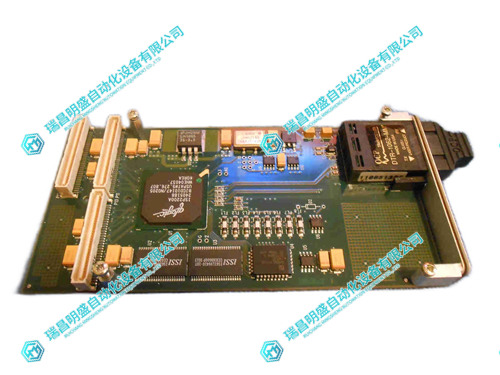

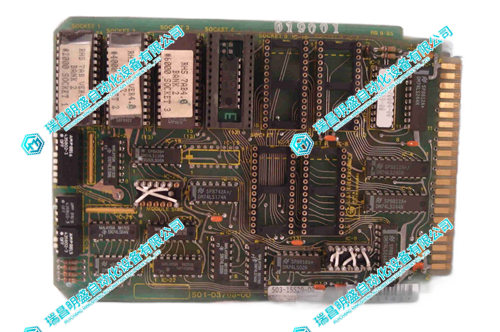

GIDINGS&LEWIS 503-15529-00存储板

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 503-15529-00 存储板:工业数据存储的可靠基石

多元应用领域

英文资料:

GIDINGS&LEWIS 503-15529-00 Storage Board: A Reliable Foundation for Industrial Data Storage

In the current era of accelerating industrial automation, efficient storage and rapid retrieval of massive data have become the key to ensuring stable equipment operation and improving production efficiency. The GIDINGS&LEWIS 503-15529-00 storage board plays an indispensable role in numerous industrial scenarios due to its excellent performance and reliable quality.

Diversified application areas

Numerical Control Machine Tool System: For CNC equipment such as lathes, milling machines, boring machines, etc., the 503-15529-00 storage board is the core carrier for storing machining programs, tool path data, and equipment operating parameters. When processing complex components, such as aircraft engine blades, the machine tool needs to run according to precise machining programs. The storage board stably stores these programs to ensure that the controller can quickly read and execute them, ensuring precise tool positioning and achieving micrometer level machining accuracy, meeting the stringent requirements of high-end manufacturing for precision machining. At the same time, real-time parameters during the operation of the equipment, such as spindle speed, feed rate, etc., are also recorded on the storage board for subsequent equipment maintenance and performance optimization analysis.

Industrial automation production line: In an automated production line, various equipment generates a large amount of data, including material conveying information, product testing data, equipment operation status, etc. The 503-15529-00 storage board stores these data in an orderly manner, providing data support for monitoring and management of the production process. On the automated assembly line of automotive parts, the storage board records the operation data of each assembly station. Once a product quality problem occurs, it can quickly trace the production process, locate the problematic link, and improve production management efficiency and product quality stability. In the material sorting system, storage boards store cargo information and sorting path data to assist sorting equipment in efficiently and accurately completing sorting tasks.

Robot control system: Industrial robots need to store a large amount of motion trajectory data, joint position information, and task instructions when performing tasks. The 503-15529-00 storage board provides sufficient storage space for the robot control system, ensuring that the robot can quickly access relevant data when performing complex tasks such as welding, handling, and sorting, achieving precise multi axis coordinated motion. For example, in the automobile welding workshop, robots accurately control the position and posture of the welding gun based on the welding trajectory data in the storage board, ensuring uniform and beautiful welding quality; In logistics warehousing, AGV robots rely on stored map data and task instructions to achieve autonomous navigation and cargo handling.

Process control and monitoring systems: Process control and monitoring systems in industries such as chemical, energy, and metallurgy require extremely high reliability for data storage. The 503-15529-00 storage board is used to store key process parameters such as temperature, pressure, flow rate, and equipment operating status data during the production process. In chemical production, real-time temperature and pressure data of the reaction kettle are recorded on the storage board. Once the parameters are abnormal, the control system can quickly analyze and take measures based on the stored data to ensure production safety.

2.产 品 展 示

3.其他产品

REOTRON 567LH-DP24直流电源

SAGEMCOM 252720938AB控制模块

SAGEMCOM 252721013AF

4.其他英文产品

1407-CGCMC module

ALSTOM AB121 Control card

ALSTOM AH116-2 Control card

| AMAT 0190-06071 | AMAT 0190-35243 | AMAT 0190-27579 |

| AMAT 0190-06073 | AMAT 0190-35250 | AMAT 0190-27580 |

| AMAT 0190-06098 | AMAT 0190-35254 | AMAT 0190-27661 |

| AMAT 0190-06120 | AMAT 0190-35255 | AMAT 0190-27707 |

| AMAT 0190-06182 | AMAT 0190-35259 | AMAT 0190-27818 |

| AMAT 0190-06212 | AMAT 0190-35278 | AMAT 0190-27886 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218