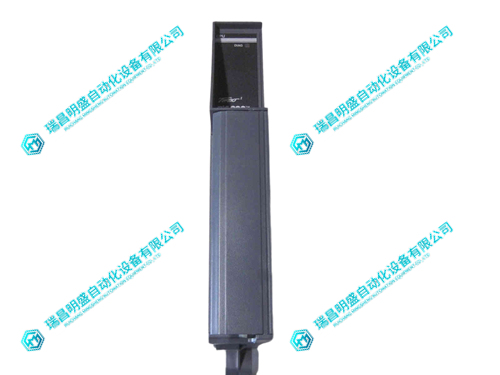

GIDINGS&LEWIS 502-03814-40输入输出模块

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 502-03814-40 输入输出模块:工业自动化的信号中枢

多元应用领域

英文资料:

GIDINGS&LEWIS 502-03814-40 Input/Output Module: Signal Center for Industrial Automation

In the complex system of industrial automation, efficient communication and precise control between different equipment and systems are crucial. The GIDINGS&LEWIS 502-03814-40 input/output module serves as a signal bridge connecting various devices and plays an indispensable role in many industrial scenarios due to its excellent performance.

Diversified application areas

CNC machine control system: For CNC machine tools, the 502-03814-40 input/output module is the core component for achieving precise machining control. When processing complex components, such as aircraft engine blades, the machine tool needs to precisely control the tool path according to programming instructions. The module quickly and accurately transmits signals from position sensors, speed sensors, etc. to the controller, enabling the controller to grasp the real-time operating status of various components of the machine tool. At the same time, the control instructions issued by the controller are transmitted to the executing mechanism, such as driving the servo motor to adjust the tool position, controlling the start and stop of the cooling system, ensuring that the machining accuracy reaches the micrometer level, and ensuring that the complex surface contour meets the design requirements.

Industrial automation production line: The assembly, sorting, conveying, and packaging systems in the automated production line rely on the 502-03814-40 input/output module to achieve signal acquisition and output control for each workstation. On the automated assembly line of automotive components, modules collect position signals of components detected by sensors and transmit them to the control system. Based on this, the control system commands the robotic arm to accurately grasp and install components, improving assembly accuracy and efficiency. In the sorting system, the product detection signal is transmitted to the control unit, which controls the sorting mechanism to accurately classify the products. In the transportation and packaging process, control the speed of the conveyor belt and the start stop of the packaging equipment to ensure the continuity and efficiency of the production process.

Servo and motion control system: In the operation of servo motors, stepper motors, or multi axis motion platforms, this input/output module serves as a data input/output interface and is the key to achieving closed-loop control and precise positioning. Taking a multi axis motion platform as an example, the module receives position feedback signals from the encoder and transmits them to the controller for analysis and processing. Based on the deviation calculation results, the controller sends control instructions to the motor driver through the module to adjust the motor speed and direction, making the platform accurately positioned. Under the requirements of high-speed and high-precision motion control, the module ensures timely and accurate data transmission, achieving stable and reliable operation of the equipment.

Robot system: The efficient operation of industrial robots and robotic arms relies on the 502-03814-40 input-output module. It supports the connection between robot sensors and actuators, achieving multi axis coordination and path planning. In logistics and warehousing, AGV robots transmit environmental perception signals from laser radar and visual sensors to the control system through modules. After processing, the control system sends instructions to the motor driver through the module to control the robot's travel path and actions.

2.产 品 展 示

3.其他产品

Prosoft 5304-MBP-PDPM控制器模块

B&R 5AP933.215C-00触摸屏

BENTLY 3500/33 149992-01控制卡背板

4.其他英文产品

IC660ELB921M Gas turbine electrical card

KUC711AE101 3BHB004661R0101 Excitation controller

ALSTOM LE109A-1 Communication circuit board

| AMAT 0190-07847 | AMAT 0190-08421 | AMAT 0190-08556 |

| AMAT 0190-09209 | AMAT 0190-08770 | AMAT 0190-08599 |

| AMAT 0190-09257 | AMAT 0190-08776 | AMAT 0190-08638 |

| AMAT 0190-09263 | AMAT 0190-08783 | AMAT 0190-08656 |

| AMAT 0190-09263 | AMAT 0190-08850 | AMAT 0190-08677 |

| AMAT 0190-09267 | AMAT 0190-08851 | AMAT 0190-08680 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218