GIDINGS&LEWIS NE23-015伺服电机

1.产 品 资 料 介 绍:

GIDINGS&LEWIS NE23-015 伺服电机:工业自动化的动力中坚

多元应用领域

英文资料:

GIDINGS&LEWIS NE23-015 servo motor: the backbone of industrial automation power

In the vast field of industrial automation, servo motors, as the key power source for achieving precise motion control, directly affect the quality and efficiency of equipment operation based on their performance. GIDINGS&LEWIS NE23-015 servo motor stands out in many industrial scenarios with its excellent design and reliable performance, becoming the core force driving industrial production towards high precision and efficiency.

Diversified application areas

CNC machine tool drive: For CNC equipment such as lathes, milling machines, boring machines, etc., the NE23-015 servo motor is a key component in achieving high-precision machining. When machining precision shaft parts on a lathe, the motor precisely drives the spindle to rotate at high speed and stability, while precisely controlling the displacement of the feed shaft. The relative position between the tool and the workpiece is controlled with micrometer level precision, ensuring that the machined shaft parts have extremely high dimensional accuracy and low surface roughness, meeting the strict requirements of the mechanical manufacturing industry for precision parts. When machining complex mold contours on a milling machine, the motor quickly responds to control system instructions and collaborates with multi axis linkage to accurately position the tool along the complex trajectory, producing exquisite mold details and ensuring the precision and quality of mold forming.

Industrial automation equipment: Automated assembly lines, conveyor systems, and assembly platforms require high precision and coordination of power output, and the NE23-015 servo motor plays a pivotal role in this regard. On the automated assembly line, it drives the conveyor device to ensure that the products flow between each workstation at a constant speed and precise position, avoiding product collisions or stacking. On the assembly platform, the motor precisely controls the movement of the robotic arm, enabling it to accurately grasp and install small components, improve assembly accuracy and efficiency, ensure product quality consistency, and assist in efficient and stable operation of industrial automation production.

Robots and Multi Axis Control Systems: The agility and precision of industrial robots and robotic arms cannot be achieved without the assistance of the NE23-015 servo motor. In the automotive welding workshop, the NE23-015 servo motors at each joint of the robot work together to precisely control the posture and position of the robotic arm based on the preset welding trajectory, allowing the welding gun to move steadily and accurately along the weld seam, ensuring uniform and beautiful welding quality. In logistics and warehousing, AGV robots rely on this servo motor to accurately control wheel speed and steering, achieving autonomous navigation, precise obstacle avoidance, and cargo handling, improving logistics operation efficiency and accuracy, and meeting the modern logistics demand for efficient and precise operation of automated equipment.

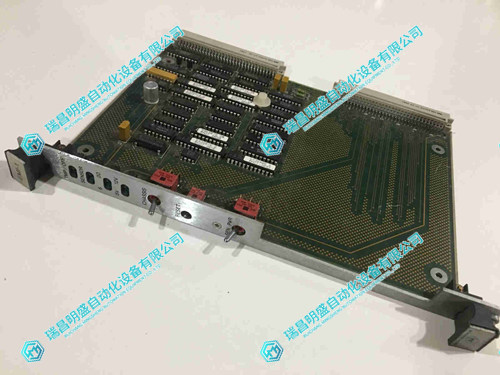

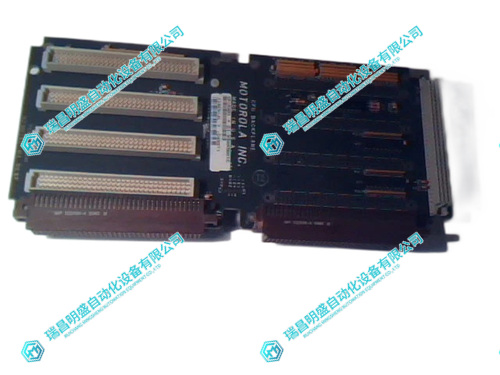

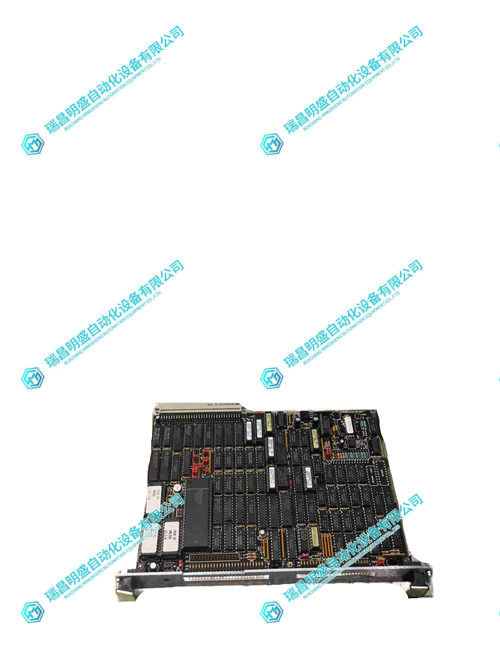

2.产 品 展 示

3.其他产品

B&R 5AP933.215C-00触摸屏

BENTLY 3500/33 149992-01控制卡背板

BENTLY 3500/15 127610-01电源卡

4.其他英文产品

ALSTOM LE109A-1 Communication circuit board

PROSOFT MVI56-MNETR module

PROSOFT MVI94-GSC interface module

| AMAT 0190-09267 | AMAT 0190-08911 | AMAT 0190-08853 |

| AMAT 0190-09267 | AMAT 0190-08922 | AMAT 0190-08855 |

| AMAT 0190-09134 | AMAT 0190-08931 | AMAT 0190-08856 |

| AMAT 0190-09139 | AMAT 0190-08964 | AMAT 0190-08858 |

| AMAT 0190-09141 | AMAT 0190-08965 | AMAT 0190-08858 |

| AMAT 0190-09153 | AMAT 0190-09009 | AMAT 0190-08875 |

| AMAT 0190-09160 | AMAT 0190-09009 | AMAT 0190-08911 |

| AMAT 0190-09160 | AMAT 0190-09027 | AMAT 0190-08922 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218