GIDINGS&LEWIS 501-03882-00接口板

1.产 品 资 料 介 绍:

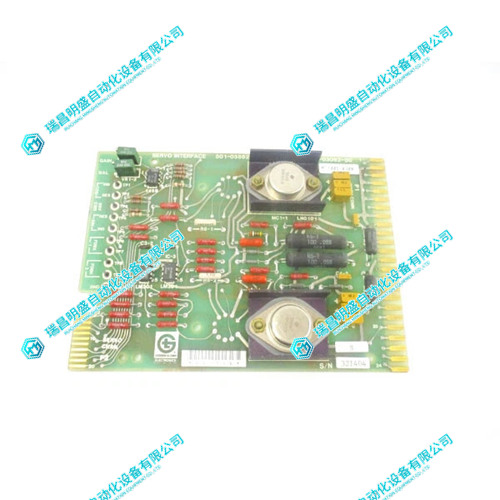

GIDINGS&LEWIS 501-03882-00 接口板:工业自动化的连接枢纽

多元应用领域

英文资料:

GIDINGS&LEWIS 501-03882-00 Interface Board: Connection Hub for Industrial Automation

In the complex system of industrial automation, efficient and stable communication and connection between devices are crucial. The GIDINGS&LEWIS 501-03882-00 interface board, with its excellent performance and meticulous design, has become a core component for signal transmission, data interaction, and device collaboration in many industrial scenarios.

Diversified application areas

CNC machine control system: For CNC machine tools, the 501-03882-00 interface board is the key to realizing signal transmission and interface management between the controller and sensors, actuators, and other modules. When machining precision shaft parts on a lathe, the interface board quickly transmits the tool position signal detected by the position sensor to the controller, and accurately conveys the control instructions issued by the controller to the servo motor and other actuators, ensuring that the tool cuts along the preset path with micrometer level accuracy, guaranteeing machining accuracy and equipment reliability, and meeting the strict requirements of precision machining in the mechanical manufacturing industry.

Industrial automation production line: The automation production line covers multiple links such as conveying, assembly, sorting, and packaging. The 501-03882-00 interface board is responsible for signal coordination and data transmission between multiple devices. On the automated assembly line, it transmits the position sensor signal of the robotic arm to the control system, and at the same time, transmits the grasping and installation instructions of the control system to the robotic arm actuator, ensuring precise and efficient assembly actions. In the sorting system, the product detection sensor signals are transmitted to the control unit to control the sorting mechanism to accurately classify products, ensuring smooth production processes and improving the overall efficiency of the production line.

Servo and multi axis motion control system: Provides interface support for servo motors, stepper motors, and multi axis drive systems, with the 501-03882-00 interface board assisting in achieving closed-loop control and motion synchronization. In a multi axis machining center, the interface board transmits the encoder feedback signals of each axis motor to the controller. The controller adjusts the motor operating parameters based on these signals to achieve multi axis coordinated motion, enabling the tool to accurately process according to complex trajectories and meet the demand for precision motion control in industrial production.

Robot and robotic arm system: Connect the sensors and control modules of industrial robots or robotic arms, and the 501-03882-00 interface board is used to issue action commands and collect feedback signals. In logistics and warehousing, AGV robots transmit environmental perception signals from laser radar and visual sensors to the control system through an interface board. After processing, the control system sends driving paths and action instructions to the motor driver through the interface board, achieving autonomous navigation, precise obstacle avoidance, and cargo handling. In industrial production, when the robotic arm performs tasks such as welding and polishing, the interface board transmits real-time force sensor and position sensor data to ensure that the robotic arm operates accurately based on the actual situation of the workpiece.

2.产 品 展 示

3.其他产品

ABB AIM0006 2RCA021397A0001P数字量模块

ABB XO08R2 1SBP260109R1001数字输出模块

FOXBORO FBM230 P0926GU数字输入模块

4.其他英文产品

DSAB-01C Trigger plate

140CRA31200 Motion module

RELIANCE 57C413B programmable controller

| SRF5360-4985-84-5-82BC-CU | SC402-048-T4 | SC905-001-01 |

| SRF5348-4485-84-5-45BC-CU | SC402-001-T5 | SC903-024-01 |

| SRF5348-4485-84-45BC-CU | SC402D23T4 | SC902NN-001-01 |

| SRF3756-4996-84-5-56BC-CU | SC403044T3 | SC942-001-01 |

| SRF3752-4984-84-5-56BC-CU | SC402-001-T2 | SC753B-001-02 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218