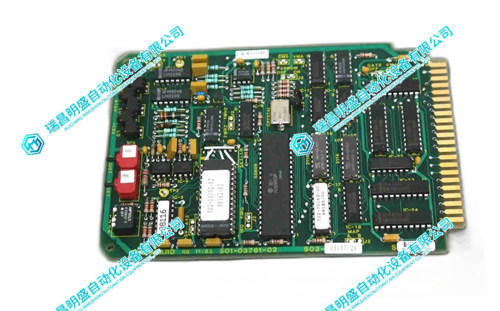

GIDINGS&LEWIS 501-03761-02 CPU板

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 501-03761-02 CPU 板:工业自动化的智能核心

多元应用领

英文资料:

GIDINGS&LEWIS 501-03761-02 CPU board: the intelligent core of industrial automation

In the complex system of industrial automation, the CPU board serves as the "brain" of the control system, and its performance directly determines the operational efficiency, control accuracy, and intelligence level of the entire industrial system. The GIDINGS&LEWIS 501-03761-02 CPU board, with its excellent design and powerful functionality, has become the core force for achieving efficient and precise control in many industrial scenarios.

Diversified application areas

Central processing and logical operations: As the core processing unit of the control system, the 501-03761-02 CPU board is responsible for executing complex logical operations and data processing. In industrial production, it quickly analyzes and processes data collected by various sensors, such as temperature, pressure, position, etc., and provides intelligent control decisions for industrial equipment based on preset control strategies and algorithms. In the chemical production process, based on the temperature, pressure, and material flow rate data inside the reaction kettle, the CPU board performs complex calculations to accurately control the opening of valves, pump speed, and other actuators, ensuring that chemical reactions proceed under optimal conditions and improving product quality and production efficiency.

Real time signal management: Efficient management of high-speed data from sensors, I/O modules, and encoders is the key to achieving precise real-time control of industrial systems on the 501-03761-02 CPU board. When the CNC machine tool is running, it collects real-time signals from the tool position encoder, processes them quickly, and feeds back the position information to the control system. At the same time, it receives motion instructions from the control system and transmits them to the motor driver in a timely manner, achieving micrometer level precision positioning and motion control of the tool, ensuring the machining accuracy of parts, and meeting the strict requirements of precision machining in the mechanical manufacturing industry.

Multi task collaborative control: supports simultaneous operation and scheduling of multiple axes and devices, and the 501-03761-02 CPU board achieves synchronization and coordination of complex production lines. On the automated assembly line of automobile manufacturing, it simultaneously controls the operation of multiple robotic arms, conveyor belts, and detection equipment. The robotic arm is responsible for grasping and installing components, the conveyor belt ensures accurate delivery of components to the assembly station, the detection equipment monitors the assembly quality in real time, and the CPU board coordinates various devices through precise task allocation and time scheduling to improve assembly efficiency and quality, ensuring efficient and stable operation of the production line.

Network and Communication Interface Management: Integrating industrial Ethernet, RS-485, or other fieldbus protocol interfaces, the 501-03761-02 CPU board enables data exchange between the control system and external devices. In the smart factory, through the industrial Ethernet interface, it uploads the operational data of production equipment to the enterprise management system, and management personnel can real-time grasp information such as production progress and equipment status. At the same time, receive production plans and control instructions from the management system, adjust equipment operating parameters, and achieve information management and remote control of the production process.

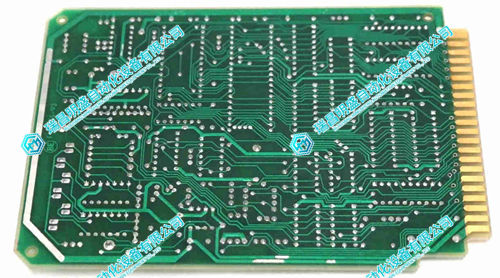

2.产 品 展 示

3.其他产品

ABB XO08R2 1SBP260109R1001数字输出模块

FOXBORO FBM230 P0926GU数字输入模块

GE IC695CPU315中央处理器模块

4.其他英文产品

RELIANCE 57C413B programmable controller

FBM224 P0926GG I / O module

IS200SPIDG1ABA combustion engine card

| SRF3632-5227-84-5-56BC-CU | SC403-013 | SC753A-010-02 |

| SR5348-4592-45B | SC403-012-T2 | SC943T200101 |

| SR5340-5370-4-45B | SC403-004-T3 | SC903NN-033-01 |

| SR489-P5-HI-A20 | SC402-037-T3 | SC903AN-001-01 |

| SR489-CASE | SC403-002-T4 | SC904NN-001-01 |

| SR469-P5-LO-A20-T | SC402-011-T3 | SC933-050-01 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218