GIDINGS&LEWIS 501-03437-00变频器模块

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 501-03437-00 变频器模块:工业调速的节能核心

多元应用领域

英文资料:

GIDINGS&LEWIS 501-03437-00 frequency converter module: the energy-saving core of industrial speed regulation

In industrial production, the speed control and efficient operation of motors are directly related to production efficiency and energy consumption. The GIDINGS&LEWIS 501-03437-00 frequency converter module, with its precise speed regulation capability and excellent energy-saving characteristics, has become a key hub for connecting power supplies and motors, and is widely used in various industrial scenarios.

Diversified application areas

CNC machine drive system: In CNC equipment such as lathes and milling machines, the 501-03437-00 frequency converter module provides flexible speed adjustment for the spindle motor and feed motor. When processing parts of different materials, the module can adjust the motor speed in real time according to cutting requirements - increasing the speed to enhance cutting force when cutting hard alloys, and reducing the speed to avoid workpiece deformation when processing thin-walled parts. By precisely controlling the motor output, the machining accuracy is ensured while reducing idle energy consumption, enabling the machine tool to maintain efficient operation under complex working conditions.

Industrial pump and fan control: In industries such as chemical and water treatment, this module is commonly used to control fluid equipment such as water pumps and fans. When the system flow demand changes, the frequency converter dynamically adjusts the motor speed, replacing the traditional valve throttling method. For example, in the central air conditioning water circulation system, the water pump speed is automatically reduced according to changes in indoor temperature, reducing pipeline pressure loss. Compared with constant speed operation, it can save more than 30% energy, while reducing equipment wear and extending service life.

Conveyor and transmission equipment: The transmission equipment such as conveyor belts and elevators in automated production lines rely on frequency converters to achieve smooth speed regulation. In the logistics sorting line, the module adjusts the conveyor belt speed according to the density of goods - increasing the speed during peak hours to accelerate the flow, reducing the speed during low peak periods to save energy, and avoiding equipment idling and wasting energy. In elevators and lifting equipment, precise control of motor start-up and braking processes is used to achieve smooth operation, reduce mechanical impact, and improve equipment safety.

Metallurgy and Heavy Machinery: In heavy equipment such as steel mills and mining crushers, the 501-03437-00 frequency converter module is responsible for heavy-duty starting and speed regulation tasks. During the steel rolling process, the speed of the rolling mill motor is adjusted in real-time according to the thickness of the steel plate to ensure rolling accuracy; When the crusher is running, it adapts to the crushing requirements of different hardness ores through speed closed-loop control, avoiding equipment overload and shutdown, and improving production continuity.

Textile and printing equipment: Precision equipment such as textile machines and printing machines require extremely high speed stability. The frequency converter module uses high-frequency pulse width modulation technology to control the motor speed fluctuation within ± 0.1%, ensuring uniform stretching of textile fibers and precise overprinting of printed patterns. In multi unit linkage equipment, synchronous speed regulation of each motor can also be achieved to ensure the coordination of the production process.

New energy and environmental protection equipment: In solar tracking systems and sewage treatment aeration equipment, modules dynamically adjust motor operation based on environmental parameters. When the solar panel tracks the sun, the inverter drives the motor to adjust the angle slowly and steadily, maximizing the absorption of light energy;

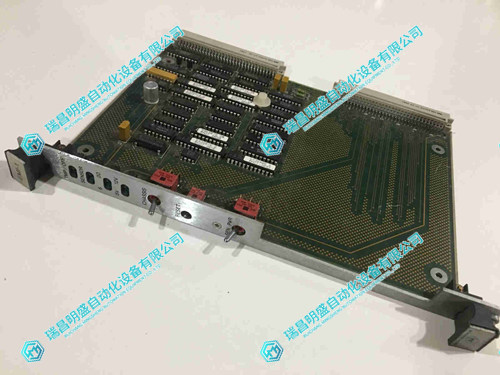

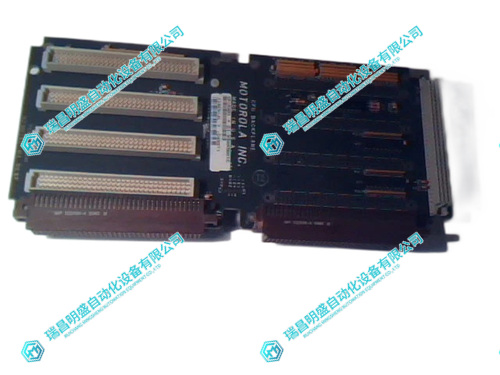

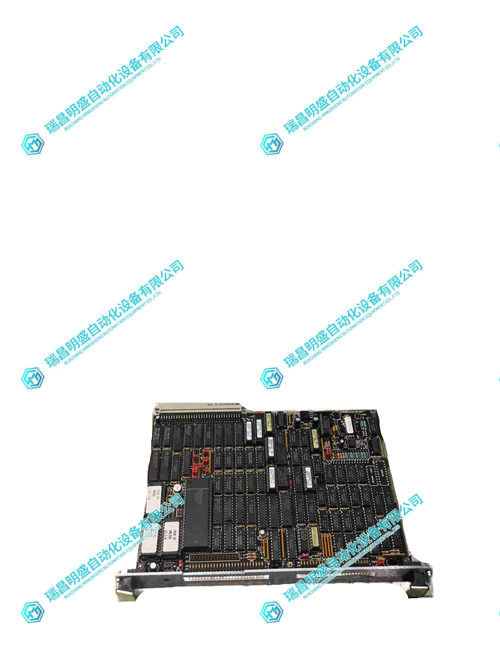

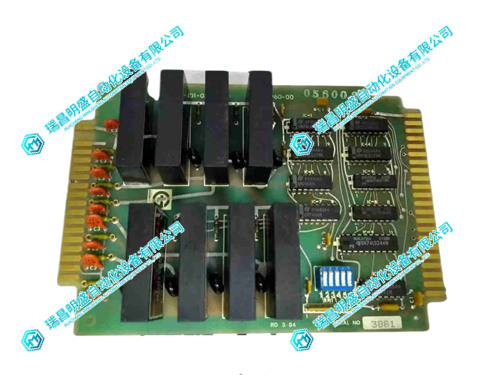

2.产 品 展 示

3.其他产品

FOXBORO FBM230 P0926GU数字输入模块

GE IC695CPU315中央处理器模块

HIMA LM002_MAX 985020002框架

4.其他英文产品

IS200SPIDG1ABA combustion engine card

GE IS220PPRFH1B 336A5026ADP2 power supply module

P0916PH P0916AL Terminal module

| SR469-P1-HI-A1-E | AMAT 0100-90517 | PFEA 113-65.1PXV |

| SR3720-3798-7-56C | AMAT 0100-93404 | PFCL 201CD-20.0KN |

| SR3720-3798-2A-56C | AMAT 0110-20001 | 57160001-UH DSTD150A ABB |

| SR3662-8292-2-48B | AMAT 0100-02409 | PFCL 201CE-20.0KN |

| SR3658-2255-7-56B | AMAT 0100-00206 | PFEA111-IP20 3BSE050090R20 |

| SR3644-4963-7-1 | AMAT 0100-94053 | 57350886 DSIM 2918 ABB |

| SR3642-4982-7-56BC-CU | AMAT 0100-71220 | PFCL 201C-50.0KN |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218