GIDINGS&LEWIS 31-50231N23 CPU板

1.产 品 资 料 介 绍:

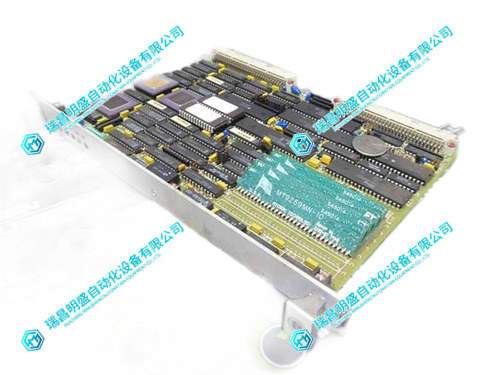

GIDINGS&LEWIS 31-50231N23 CPU 板:工业自动化的智慧中枢

多元应用领域

英文资料:

GIDINGS&LEWIS 31-50231N23 CPU board: the intelligent hub of industrial automation

In the complex architecture of industrial automation, the CPU board serves as the core control unit, responsible for data processing, logical operations, and equipment coordination. Its performance directly affects the operational efficiency of the entire industrial system. The GIDINGS&LEWIS 31-50231N23 CPU board, with its excellent design and powerful functionality, has become a key force in achieving efficient and precise control in many industrial scenarios.

Diversified application areas

In the field of CNC machine tools: For CNC machine tools such as lathes, milling machines, grinders, and machining centers, the 31-50231N23 CPU board is the core to ensure machining accuracy and stable equipment operation. When precision shaft parts are machined on a lathe, it collects various signals such as tool position sensors and spindle speed sensors in real time. After high-speed processing, it precisely controls the operation of the servo motor, allowing the tool to cut along the preset trajectory with micrometer level accuracy, ensuring that the machined shaft parts have extremely high dimensional accuracy and low surface roughness, which meets the strict standards of precision component machining in the mechanical manufacturing industry. When processing complex molds on a machining center, the CPU board coordinates multi axis linkage, accurately plans the motion paths of each axis based on the mold design drawings, achieves high-precision processing of complex surfaces, and improves the quality and efficiency of mold manufacturing.

Automated production line: The automated production line covers multiple links such as conveyor systems, sorting machinery, assembly lines, etc. The 31-50231N23 CPU board plays a key role in overall coordination. In the conveying system, it adjusts the motor speed of the conveyor belt in real time according to the material flow rate and production rhythm of the production line, ensuring smooth and efficient conveying of materials, and avoiding material accumulation or idle waste. During the operation of sorting machinery, the CPU board quickly processes the product feature data detected by sensors, such as size, weight, color, etc., and commands the sorting mechanism to accurately classify the products to the corresponding channels, improving sorting accuracy and efficiency. In the assembly line stage, it precisely controls the movement of the robotic arm, enabling it to accurately grasp and install components according to preset programs, improving assembly accuracy and efficiency, and ensuring the smooth operation of the entire automated production line.

Motion control system: In the motion control system that drives servo motors and stepper motors to achieve multi axis linkage control, the 31-50231N23 CPU board is the core for achieving precise motion. In a multi axis engraving machine, it simultaneously processes the position feedback signals and control instructions of multiple axis motors, accurately calculates the operating parameters of each axis motor through complex algorithms, achieves multi axis coordinated motion, and enables engraving tools to accurately engrave according to the design pattern, meeting the high-precision engraving needs of industries such as advertising production and handicraft processing. In the AGV (Automated Guided Vehicle) system of automated warehousing and logistics, the CPU board controls the operation of the AGV's motor, achieving autonomous navigation, precise positioning, and cargo handling of the AGV, and improving the automation level and operational efficiency of warehousing and logistics.

2.产 品 展 示

3.其他产品

HIMA LM002_MAX 985020002框架

HIMA X-BLK01 632590802安全控制模块

HIMA X-DI1601 985210222数字输入模块

4.其他英文产品

P0916PH P0916AL Terminal module

P0916PH P0916JS module

RV33-1 Automation module

| SR3642-4822-56BC-CU | AMAT 0100-00063 | DSDI452 ABB |

| SR3640-8634-7-56 | AMAT 0100-35414 | PFEA111 |

| SR3640-852-56C | AMAT 0100-01739 | 57160001-AK DSDO120 ABB |

| SR3640-8364-7-56C | AMAT 0100-91103 | 26390582-BL DSTK128 ABB |

| SR3640-8354-7-56C | AMAT 0100-00086 | 57310001-CC DSPC171 ABB |

| SR3640-8293-7-56HC | AMAT 0100-00109 | PFCL 201CE-50.0KN |

| SR3640-8293-7-13-48BC | AMAT 0100-00941 | 57310001-KN/2 DSTC175 ABB |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218