GIDINGS&LEWIS 501-09791-00解码器板

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 501-09791-00 解码器板

一、产品概述

二、技术参数(典型特性,实际数值需参考官方资料)

英文资料:

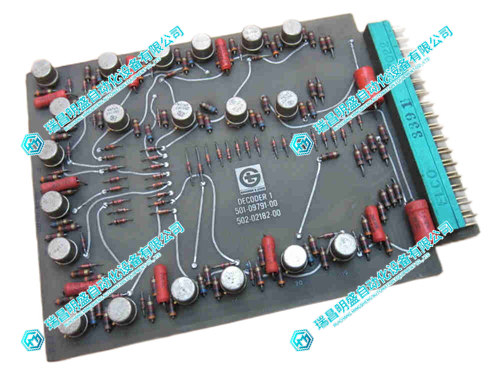

GIDINGS&LEWIS 501-09791-00 decoder board

In the process of industrial control and motion control systems moving towards high precision and intelligence, the GIDINGS&LEWIS 501-09791-00 decoder board serves as the core signal processing hub, undertaking a critical mission to provide solid support for the precise operation and efficient control of the system.

1、 Product Overview

The GIDINGS&LEWIS 501-09791-00 decoder board is designed for complex industrial environments and is a functional module dedicated to deep processing of output data from encoders, sensors, or other digital signal sources. Its workflow is like a precise signal "translation" and "organization". It first receives complex data from various signal sources, which may exist in different encoding forms, frequencies, and transmission protocols. Subsequently, the decoder board uses built-in advanced algorithms and circuits to decode these data, converting them from obscure and difficult to understand encoding formats into a universal form that the system can easily understand. Subsequently, through a series of conversion and processing steps, the signal is further optimized to ultimately output accurate and reliable position, velocity, or status information for the controller. In core industrial equipment such as CNC machine tools, servo drive systems, and automated production equipment, it serves as a key feedback interface module, like the system's "perception nerve", providing real-time feedback on the equipment's operating status to the control system, enabling the system to make timely and accurate decisions based on this information, ensuring that the equipment is always in the best operating state, and the production process can be efficiently and stably promoted.

2、 Technical parameters (typical characteristics, actual values need to refer to official materials)

Accurate functional positioning: Its core function focuses on efficient and accurate decoding and processing of encoders and various digital signals. Whether it is pulse signals from high-precision encoders for precise positioning or digital information from sensor outputs reflecting device operating status, this decoder board can accurately identify and process them, providing a reliable data foundation for subsequent control processes.

Wide compatibility of input signals: Depending on specific model differences, it can flexibly support incremental or absolute encoder signals. Incremental encoder signals are commonly used to measure the relative displacement and velocity of equipment. By monitoring the number and frequency of pulses, the decoder board can accurately calculate the motion changes of the equipment; The absolute value encoder signal can provide absolute position information of the device, playing an irreplaceable role in some application scenarios that require extremely high position accuracy and require the device to accurately know its own position even after power failure and restart. This wide compatibility with different types of encoder signals greatly expands its application scope in various industrial equipment.

Efficient output format: After decoding and processing, the signal is output in a standardized digital signal format. This standardized design enables the controller to directly and quickly recognize and process these signals without the need for complex format conversion and adaptation, effectively improving data transmission and system response speed, ensuring that the control system can respond in a timely manner

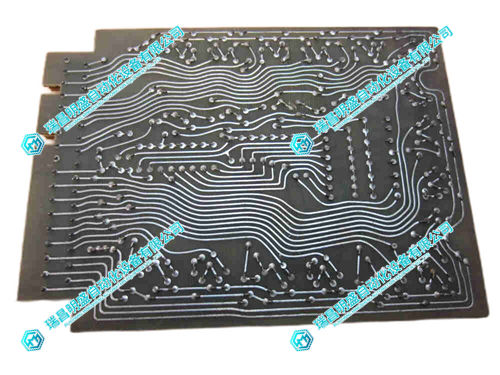

2.产 品 展 示

3.其他产品

ICS TRIPLEX T9451模块

ABB DDC779BE02 3BHE006805R0002控制模块

Agilent E1406A模拟输入输出模块

4.其他英文产品

BACHMANN MP226/EW Expansion module

NTCF22 Voltage monitoring module

PM866K01 3BSE050198R1 DCS controller

| PXIe-8388 | R45HEAA-R2-NS-NV-00 | S33HNAA-RNNM-00 |

| PXIe-8384 | R84GENA-R2-NS-NV-00 | S24HMNA-HNNM-00 |

| PXIe-8234 | R43GENA-TS-M3-VS-02 | R22GMNA-NP-NS-NV-03 |

| PXIe-8135 | R45HCNA-R2-NS-NV-00 | S34HNNA-RNNM-00 |

| PXIe-8133 | SC104-001-T4 | S21HNNA-HGNS-02 |

| PXIe-8130 | R34JENT-TS-LB-NV-01 | R34KMNC-R2-NS-NV-00 |

| PXIe-8115 | R34KENP-R2-NS-NV-00 | R32GENC-HS-ND-VS-00 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218