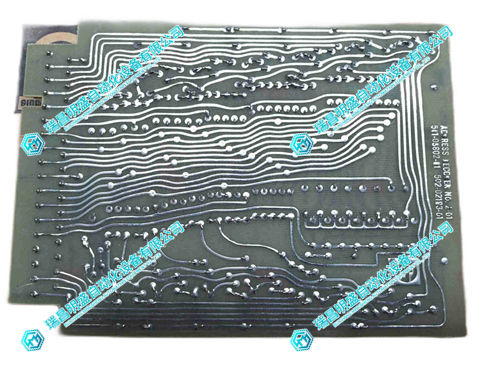

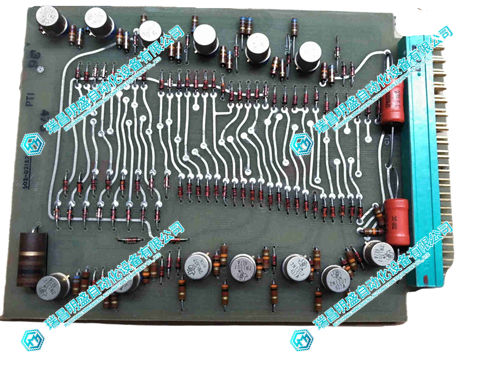

GIDINGS&LEWIS 502-02183-01存储板

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 502-02183-01 存储板

一、产品概述

二、技术特性

英文资料:

GIDINGS&LEWIS 502-02183-01 Storage Board

In the current era of increasingly complex industrial automation and numerical control systems, with constantly increasing requirements for data processing and storage, the GIDINGS&LEWIS 502-02183-01 storage board plays a crucial role as a key data storage and management hub in various industrial equipment, providing solid guarantees for the stable operation and efficient data processing of the system.

1、 Product Overview

The GIDINGS&LEWIS 502-02183-01 storage board is carefully designed for data storage and fast access requirements in industrial environments. It bears the responsibility of storing a large amount of critical data, including equipment operating parameters, processing technology files, system configuration information, and various real-time collected production data. In the entire industrial control system, the storage board is like a precise data "warehouse", which not only securely and stably stores various types of data, but also quickly and accurately retrieves data when needed by the system for use by controllers, computing modules and other equipment, ensuring smooth transmission and efficient utilization of data in the industrial production process, and avoiding problems such as system operation lag and production interruption caused by poor data storage and retrieval.

2、 Technical characteristics

Large capacity storage capability: With excellent large capacity storage characteristics, it can accommodate massive amounts of industrial data. Whether it is a complex CNC machining program that contains detailed information such as tool paths and cutting parameters, or long-term accumulated equipment operation status data in automated production lines, the storage board can easily handle it. This feature allows industrial enterprises to avoid frequent concerns about insufficient data storage space, and can store various key data in a long-term and stable manner, providing rich data support for production process traceability, process optimization, and equipment maintenance.

High speed data reading and writing: With high-speed data reading and writing performance, it can complete data storage and reading operations in a very short time. Real time data is crucial in industrial production sites. For example, in the process of CNC machining, the controller needs to quickly adjust the machining parameters based on real-time collected tool wear data, workpiece machining status, and other information. This requires the storage board to be able to quickly read relevant data and transmit it to the controller. This storage board, with its high-speed read and write capabilities, can meet the needs of industrial systems for fast data processing, ensuring rapid system response and efficient and accurate production process advancement.

Data stability and reliability: The use of industrial grade high-quality storage chips and advanced circuit design greatly ensures the stability and reliability of data storage. In industrial environments, there are many unfavorable factors such as electromagnetic interference, temperature fluctuations, and unstable power supply, which can easily cause data damage or loss. The GIDINGS&LEWIS 502-02183-01 storage board effectively resists these interferences through excellent electromagnetic shielding design, temperature compensation technology, and power management mechanism, ensuring that data remains complete and accurate throughout the storage process. Even under extremely harsh working conditions, it can reliably store data,

2.产 品 展 示

3.其他产品

ABB DDC779BE02 3BHE006805R0002控制模块

Agilent E1406A模拟输入输出模块

Agilent E1740A高速数字信号模块

4.其他英文产品

PM866K01 3BSE050198R1 DCS controller

5X00063G01 Ovation analog module

Reliance DDS-LPS Interface component module

| PXIe-6545 | R45HCNA-TS-LF-NV-00 | S24HNNA-RNNM-00 |

| PXIe-6544 | SC103 | S32HNNA-RNVM-02 |

| PXIe-6363 | R43HEAA-R2-NS-NV-00 | R45GCAA-R2-NS-NV-80 |

| PXIe-6259 | R21HSNA-R1-NS-VS-04 | R32GENP-R2-NS-NV-00 |

| PXIe-5673E | R88SENA-T2-SS-NV-03 | S32GMNA-RNNE-00 |

| PXIe-5665 | R34JENC-R2-NS-VS-00 | R33HENC-R2-NS-NV-00 |

| PXIe-5653 | R33HDNC-R2-NS-NV-00 | R33GENC-TS-NS-NV-00 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218