GIDINGS&LEWIS 502-02426-01信号转换器

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 502-02426-01 信号转换器

产品概述

技术参数

应用场景

英文资料:

GIDINGS&LEWIS 502-02426-01 Signal Converter

In industrial automation systems, abnormal signal format differences between different devices become obstacles to collaborative operation. GIDINGS&LEWIS 502-02426-01 signal converter, as a professional "signal translator", accurately solves signal adaptation problems and ensures smooth transmission of system information flow.

Product Overview

GIDINGS&LEWIS 502-02426-01 signal converter is a key interface device in industrial control, with the core function of realizing the conversion and adaptation of different types of signals. It can safely convert signals from controllers, sensors, or actuators (such as analog and digital signals, signals of different levels) into a format recognizable by the target device, ensuring the accuracy and compatibility of signal transmission. It is widely used in scenarios such as CNC machine tools, automated production lines, servo systems, and is an important link connecting various aspects of the system.

Technical Specifications

Signal conversion capability: Supports bidirectional conversion of analog (current/voltage) and digital signals, compatible with multiple level standards (such as TTL, RS485), and meets the diverse signal requirements of industrial equipment.

Electrical isolation design: It has industrial grade isolation function, blocks interference between different circuits, and ensures signal stability in strong electromagnetic environment, especially suitable for complex scenarios such as metallurgy and chemical industry.

High speed response performance: low conversion delay, millisecond level response speed, meeting real-time control requirements, such as dynamic signal feedback and instruction execution in automated production lines.

Modular installation: Adopting a slot style design, it is easy to quickly integrate into the system, and can be directly plugged and replaced during maintenance, reducing downtime.

Environmental adaptability: Industrial grade protection, able to withstand high temperatures, vibrations, and electromagnetic interference, and maintain stable operation under harsh working conditions.

Application scenarios

Numerical Control Machine Tool: Convert the analog signals of sensors (such as temperature and pressure) into digital signals and transmit them to the main control system. At the same time, convert the digital instructions of the controller into servo driven recognizable analog signals to ensure machining accuracy.

Automated production line: adapted to different signal types at different workstations (such as digital signals from photoelectric sensors and analog instructions from PLCs), ensuring signal coordination in material conveying, assembly, and other processes to maintain production rhythm.

Servo and motion control: Convert the digital feedback signal of the motor encoder and the analog control instructions of the controller to achieve precise control of speed and position, and improve the accuracy of equipment motion.

Process control industry: In metallurgical and chemical production, various sensors and control systems are connected to unify signal formats, ensuring accurate collection of process parameters (such as flow rate and liquid level) and effective execution of control instructions.

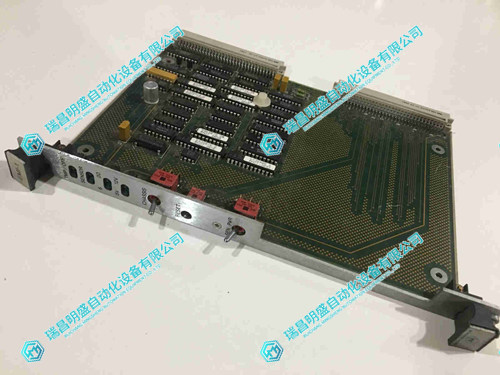

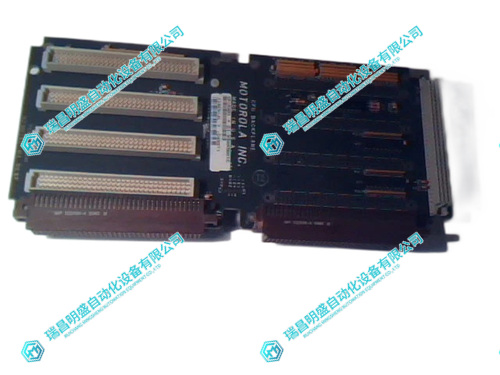

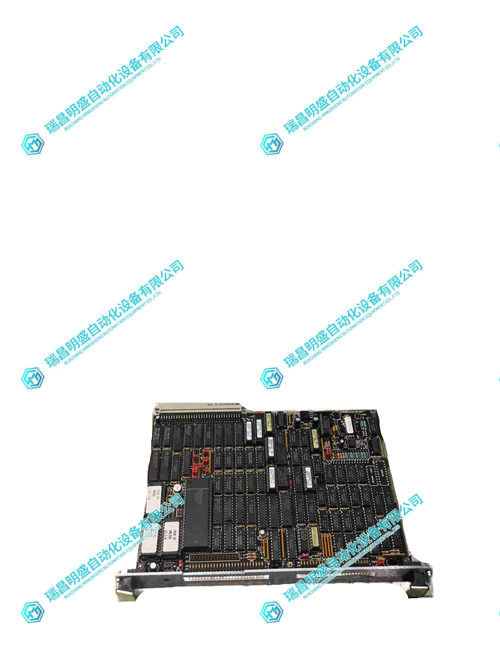

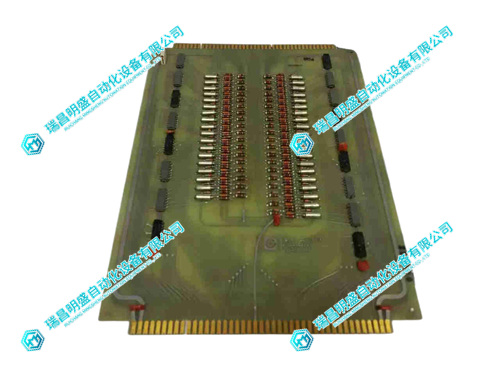

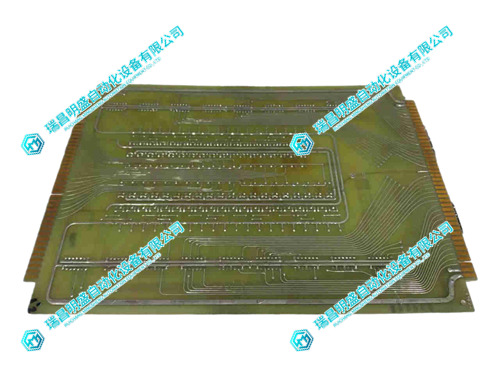

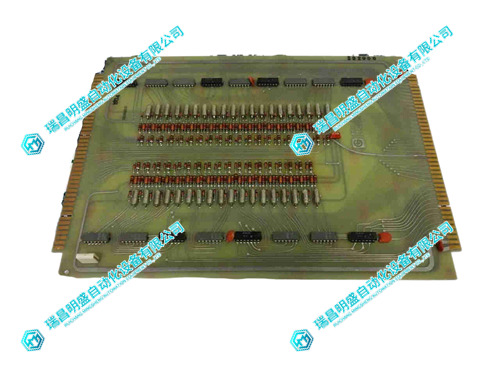

2.产 品 展 示

3.其他产品

DEIF GPU/2/GS控制器

HITACHI LYA010A控制卡

MOOG D136-001-007控制器

4.其他英文产品

WOODWARD 8440-1713 D Control the governor

TRICONEX EPI3382 Control card

ICS TRIPLEX 9100 base

| PMB33F-00100-02 | 70 AS 46b-E | XV7717C |

| PMB33F-00100-01 | NICL01 | P21NRXC-LSS-NS-06 |

| PMB33F-00100-00 | IMDSO04 | M22NRXA-JNN-NS-00 |

| PMB33E-20216-03 | 07EA80 | N31HLLL-LNK-NS-01 |

| PMB33E-20216-02 | IMAMM03 | M21NSXA-LNF-NS-02 |

| PMB33E-20216-01 | AMAT 0100-90941 | P22NRXB-LDF-NS-00 |

| PMB33E-20216-00 | 07BE62R1 | 5730030-UR DSAO 130 |

| PMB33E-20214-03 | IMCOM04 | 57160001-SH DSTD 306 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218