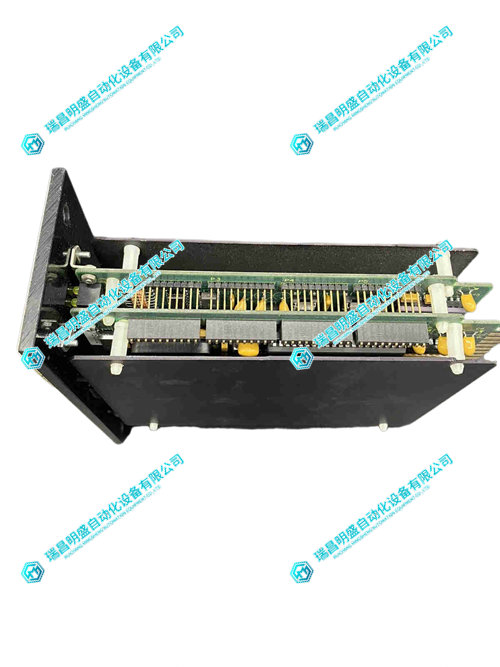

GIDINGS&LEWIS 503-17176-00 CPU 板

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 503-17176-00 CPU 板

一、产品概述

二、技术参数(典型特性,实际数值需参考官方资料)

英文资料:

GIDINGS&LEWIS 503-17176-00 CPU board

In the field of industrial automation, the efficient and precise operation of systems relies heavily on the strong support of core processing units. The GIDINGS&LEWIS 503-17176-00 CPU board, with its outstanding performance, has become the undisputed "brain" of industrial automation systems, deeply empowering various complex industrial scenarios.

1、 Product Overview

The GIDINGS&LEWIS 503-17176-00 CPU board serves as the core hub of industrial automation systems, fully responsible for executing control logic, processing massive data, and coordinating the collaborative operation of various modules. Its workflow is like a precise symphony performance, where various signals from input modules, sensors, and communication modules converge like notes from different instruments. The CPU board performs deep analysis and processing of these signals with high-speed logical computing capabilities, and then sends precise control instructions to the output module, servo driver, and actuator to ensure that each link is closely coordinated and consistent. From precision CNC machining, to efficient automated production lines, to flexible and precise robot systems, this CPU board is widely used in various key industrial scenarios and has become a key force in promoting industrial automation processes.

2、 Technical parameters (typical characteristics, actual values need to refer to official materials)

Powerful processing capability: Equipped with a high-performance industrial CPU, it is like having a super "smart chip" that can easily cope with the challenges of complex logical operations and multitasking parallel processing. Whether it is the complex tool path planning calculations required for CNC machining of complex parts, or the simultaneous processing of status monitoring and control instructions for multiple workstations in automated production lines, it can ensure efficient and orderly execution of various tasks with excellent computing performance, meeting the strict requirements of industrial production for real-time and accuracy.

Rich interface types: Excellent compatibility, seamless integration with internal buses, communication modules, and I/O modules. The internal bus is like an information highway, ensuring high-speed and stable transmission of data within the system; The communication module interface can flexibly connect industrial Ethernet, serial port, and fieldbus, facilitating efficient data exchange with external devices such as PLC, servo drive, and HMI system; The I/O module interface is responsible for accurately receiving and outputting various control signals, achieving precise control of various parts of the system, and building an interconnected and collaborative industrial automation ecosystem.

Efficient storage capability: Integrated RAM/ROM provides solid data storage support for system operation. Among them, RAM is used for fast reading and writing of data during program execution, ensuring rapid system response; ROM is used to store critical control programs, process parameters, and valuable historical data. Even in emergency situations such as system power outages, historical data and important parameters can still be fully saved, providing strong support for the rapid recovery and operation of the system after restart, as well as subsequent data analysis and process optimization.

2.产 品 展 示

3.其他产品

XYCOM XVME-674控制模块

5SHY3545L0010 3BHB013088R0001 ABB IGBT模块

ABB 3BHE009681R0101 GVC750BE101 2023.04.22现货

4.其他英文产品

MVME61006E-0163 controller card

PM864A 3BSE018162R1 Control processor

REF542plus Operation panel

| PMB33E-20214-02 | DIO00 | PWM3624-5579-7-1 |

| PMB33E-20214-01 | 07EA90-S | P22NSXC-LNN-NS-02 |

| PMB33E-20214-00 | IPCHS02 | 57120001-PC DSAX 110 |

| PMB33E-20201-03 | PHBAOT1500S100 | 3BSE019297R1 DSRF 197 |

| PMB33E-20201-02 | NKTU113 | 57160001-MA DSTX 120 |

| PMB33E-20201-01 | 70 BL 30a | 57120001-MZ DSTA 191 |

| PMB33E-20201-00 | NTAI02 | PFTL301E 0.5KN 3BSE019050R500 |

| PMB33E-20200-03 | 07PS63R3 | M21NRXC-JNN-NS-00 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218