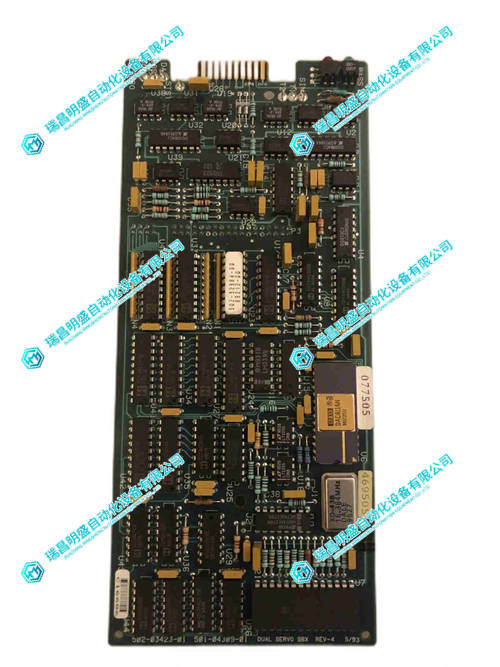

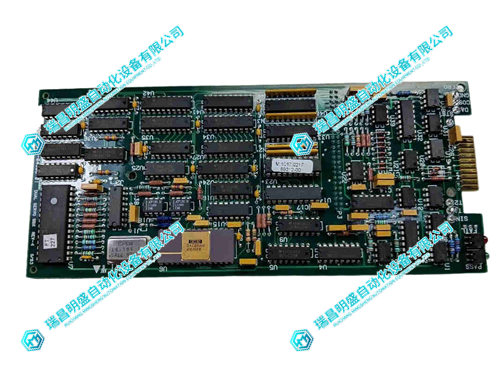

GIDINGS&LEWIS 501-04309-01双伺服驱动板

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 501-04309-01 双伺服驱动板

一、产品概述

二、技术参数(典型特性,实际数值需参考官方资料)

英文资料:

GIDINGS&LEWIS 501-04309-01 Dual Servo Drive Board

In the complex system of industrial automation, precise and efficient power control is the key to ensuring stable operation of equipment and achieving high-precision operations. GIDINGS&LEWIS 501-04309-01 dual servo drive board, as an execution module specially designed for industrial applications, plays a crucial role in multi axis linkage control scenarios with its unique dual channel design and excellent control performance.

1、 Product Overview

GIDINGS&LEWIS 501-04309-01 dual servo drive board is an extremely important execution component in industrial automation systems. Its core function is to drive two servo motors simultaneously, achieving precise control of motor speed, position, and torque. When working, it is like a sharp "information receiver", accurately receiving command signals from the main control system, and then quickly converting these signals into synchronous control signals, which are respectively transmitted to two servo motors. With this excellent control capability, the drive board has been widely used in precision machining of multi axis machine tools, flexible control of robot systems, and efficient operation of automated production lines, becoming a key driving force for promoting industrial automation processes, improving production efficiency and product quality.

2、 Technical parameters (typical characteristics, actual values need to refer to official materials)

Multi control mode: supports three modes: closed-loop position control, speed control, and torque control. In closed-loop position control mode, the drive board can accurately compare the actual position of the servo motor with the preset position based on feedback signals, adjust the output in real time, and ensure that the motor positioning accuracy reaches the micrometer level, meeting the extremely high precision requirements for tool position when machining precision parts with CNC machine tools. In speed control mode, the motor speed can be stably controlled to maintain smooth operation within a wide speed range, with minimal speed fluctuations, meeting the requirements of scenarios such as uniform speed conveying of materials by conveyor belts in automated production lines. The torque control mode endows the drive board with the ability to accurately adjust the output torque of the motor, which can adjust the torque in real time according to load changes, ensuring precise control of the grasping force when the robot grasps objects of different weights, avoiding damage or falling of the objects.

Dual channel parallel drive: With a dual channel design, it can simultaneously drive two servo motors to achieve dual axis collaborative work. This design greatly improves the system integration and control efficiency. In a multi axis motion platform, it can accurately control the synchronous motion of two axes, ensuring the accuracy of the motion trajectory; In an automated production line, the execution equipment of two workstations can be driven simultaneously to achieve efficient collaborative operations and improve overall production efficiency.

Flexible input signal: supports digital and analog command input, and can seamlessly integrate with various types of main control systems. Digital input can quickly respond to discrete control signals issued by the system, such as device start stop, forward and reverse commands, etc; Analog input is suitable for scenarios that require continuous adjustment of control parameters,

2.产 品 展 示

3.其他产品

ABB LDGRB-01 3BSE013177R1数字量输入/输出模块

ABB PP846 3BSE042238R1工业触摸屏

ABB PP846A 3BSE042238R2人机界面触摸屏

4.其他英文产品

ICS TRIPLEX T9110 Communication module

ICS TRIPLEX T9402 Power supply module

ICS TRIPLEX T9432 Programmable module

| PMB33E-20214-02 | DIO00 | PWM3624-5579-7-1 |

| PMB33E-20214-01 | 07EA90-S | P22NSXC-LNN-NS-02 |

| PMB33E-20214-00 | IPCHS02 | 57120001-PC DSAX 110 |

| PMB33E-20201-03 | PHBAOT1500S100 | 3BSE019297R1 DSRF 197 |

| PMB33E-20201-02 | NKTU113 | 57160001-MA DSTX 120 |

| PMB33E-20201-01 | 70 BL 30a | 57120001-MZ DSTA 191 |

| PMB33E-20201-00 | NTAI02 | PFTL301E 0.5KN 3BSE019050R500 |

| PMB33E-20200-03 | 07PS63R3 | M21NRXC-JNN-NS-00 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218