Rexroth VT-HNC100-1-23W-08-S-0 数字轴控制器

1.产 品 资 料 介 绍:

- 单轴控制精度出众:Rexroth VT-HNC100-1-23W-08-S-0 是专业数字轴控制器,主打单轴精准控制,能精细调节轴的位置、速度和扭矩,像数控机床的主轴转动、精密机床的刀具位移,重复定位误差极小,确保加工件尺寸精准,减少废品率。

- 适配液压 / 电动轴场景:既能对接液压驱动轴,也能适配电动驱动轴,广泛用于注塑机、锻压设备、重型机床等场景,可直接兼容 Rexroth 系列驱动部件,也能适配部分第三方轴驱动设备,不用大改现有系统就能升级。

- 宽压供电易搭配:支持 24V 直流标准工业电源,和车间常见的控制柜电源直接匹配,不用额外定制专用电源,接线时不用反复调整电压适配,安装效率高。

- 恶劣环境稳运行:能在 0℃~60℃温度范围工作,防尘防潮性能出色,面对液压车间的油污、机械车间的粉尘,以及轻微电磁干扰,都能稳定输出控制指令,不容易因环境问题停机。

- 响应速度超及时:处理轴控制指令的延迟低,轴的启停、调速、定位能快速响应,比如锻压设备的实时压力调节、机床的紧急轴制动,瞬间跟进操作需求,避免动作滞后导致的加工误差。

- 安装灵活省空间:体积紧凑,支持面板安装或导轨安装,能轻松嵌入设备控制柜,和其他控制模块搭配布局时不占太多空间,尤其适合控制柜内元件密集的场景。

- 故障排查超简单:带清晰的状态指示灯和故障代码显示,电源通断、通信是否正常、轴运行是否异常,看灯或代码就能初步判断问题,维修人员不用逐个检测元件,大幅缩短排查时间。

- 编程调试易上手:支持通过专用软件或面板按键设置参数,界面直观,有基础工控知识的人员,短时间内就能学会调整轴的运行参数、设定定位目标,不用钻研复杂编程逻辑。

- 安全防护全方位:自带过流、过压、过热保护功能,当轴驱动电流异常、供电电压不稳或控制器温度过高时,会自动触发保护机制,避免控制器损坏,同时防止轴设备过载引发安全事故。

- 耐用性经得起考验:采用工业级耐磨、抗腐蚀材质,能承受设备运行时的轻微震动,符合国际工业安全标准,长期 24 小时连续工作也不易出故障,减少维护次数和成本。

Rexroth VT-HNC100-1-23W-08-S-0 数字轴控制器 英文资料:

Outstanding single axis control accuracy: Rexroth VT-HNC100-1-23W-08-S-0 is a professional digital axis controller that focuses on precise single axis control. It can finely adjust the position, speed, and torque of the axis, such as the spindle rotation of CNC machine tools and the tool displacement of precision machine tools, with extremely small repeat positioning errors, ensuring accurate workpiece size and reducing scrap rates.

Adapting to hydraulic/electric shaft scenarios: It can be used to connect hydraulic drive shafts as well as electric drive shafts, and is widely used in injection molding machines, forging equipment, heavy-duty machine tools, and other scenarios. It can be directly compatible with Rexroth series drive components and can also adapt to some third-party shaft drive equipment. It can be upgraded without major changes to the existing system.

Wide voltage power supply easy to match: supports 24V DC standard industrial power supply, directly matches with common control cabinet power supply in the workshop, does not require additional customized dedicated power supply, does not need to repeatedly adjust voltage adaptation during wiring, and has high installation efficiency.

Stable operation in harsh environments: capable of working within the temperature range of 0 ℃~60 ℃, with excellent dust and moisture resistance. Faced with oil stains in the hydraulic workshop, dust in the mechanical workshop, and slight electromagnetic interference, it can stably output control commands and is not easily shut down due to environmental issues.

Super timely response speed: The delay in processing axis control instructions is low, and the start stop, speed regulation, and positioning of the axis can respond quickly, such as real-time pressure adjustment of forging equipment and emergency axis braking of machine tools, instantly following up on operational requirements and avoiding machining errors caused by action lag.

Flexible installation and space saving: Compact in size, supports panel or rail installation, can be easily embedded in equipment control cabinets, and does not take up too much space when laid out with other control modules, especially suitable for scenarios with dense components inside the control cabinet.

Troubleshooting is extremely simple: with clear status indicator lights and fault code displays, power on/off, normal communication, and abnormal shaft operation, the problem can be preliminarily judged by looking at the lights or codes. Maintenance personnel do not need to test each component one by one, greatly reducing troubleshooting time.

Easy to use programming and debugging: supports setting parameters through dedicated software or panel buttons, with an intuitive interface. Personnel with basic industrial control knowledge can learn to adjust axis operating parameters and set positioning targets in a short period of time without delving into complex programming logic.

Comprehensive safety protection: It comes with overcurrent, overvoltage, and overheating protection functions. When the shaft drive current is abnormal, the power supply voltage is unstable, or the controller temperature is too high, the protection mechanism will be automatically triggered to avoid damage to the controller and prevent overload of the shaft equipment from causing safety accidents.

Durability can withstand the test: Made of industrial grade wear-resistant and corrosion-resistant materials, it can withstand slight vibrations during equipment operation, comply with international industrial safety standards, and work continuously for 24 hours without easy failures, reducing maintenance frequency and costs.

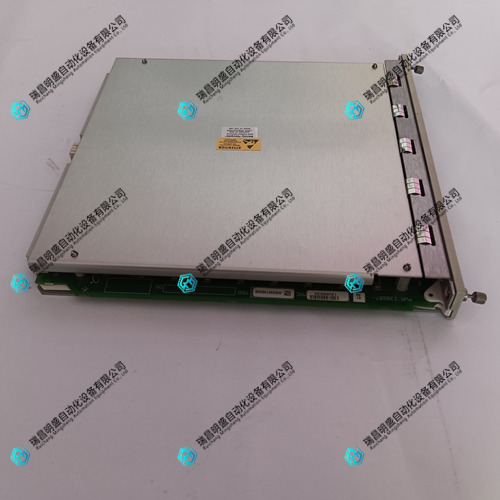

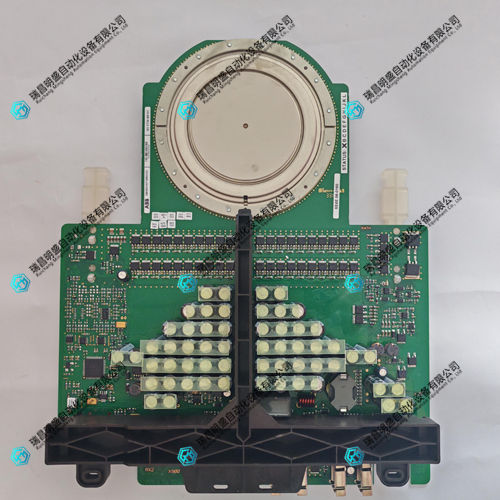

REXROTH VT-HNC100-1-23W-08-S-0 数字轴控制器 产品展示

产品视频

3.其他产品

TRICONEX AI2351 7400210-010 模块底座

TRICONEX AI2361 7400210-020处理器模块

TRICONEX AI3351分析输入模块

4.其他英文产品

MATROX Y7116-04 Controller Module

MASONEILAN SVI2-21123121 Valve Positioner

EMERSON VE4003S2B9 Analog Input Module

| IC3600PVZA1 | 531X189LTBAKG1 | IC3600EPSM1E1B |

| IC3600PTJA4A | 531X189LTBAJG1 | IC3600EPSM1 |

| IC3600PTJA4 | 531X189LTBAHG1 | IC3600EPSK2 |

| IC3600PSZA1 | 531X187VCTADG1 | IC3600EPSK1 |

| IC3600PCZA1 | 531X187VCTABH1 | IC3600EPSH1D |

| IC3600LTGA1 | 531X187VCTABG1 | IC3600EPSH1B1E |

| IC3600LTDA1C | 531X186CPSAGG1 | IC3600EPSH1B1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218