TEL Tokyo Electron EC81-000053-11数字量控制板卡

1.产 品 资 料 介 绍:

中文资料:

TEL Tokyo Electron EC81-000053-11 数字量控制板卡(Digital I/O Control Board) 是用于TEL半导体设备中的关键控制模块之一,负责数字输入/输出信号的处理与执行控制任务。该板卡在TEL的多个核心设备系统中广泛部署,尤其用于执行机械联动、设备状态监控、安全联锁及工艺流程逻辑控制。

一、基本信息

产品名称:数字量控制板卡

产品型号:EC81-000053-11

制造商:Tokyo Electron Ltd.(TEL)

板卡类型:数字输入/输出控制模块(Digital I/O Board)

部署位置:设备电控机柜或模块控制系统中

二、主要功能

数字信号输入处理(DI)

接收来自传感器、限位开关、按钮、继电器等外部设备的开关信号;

判断设备运行状态、物理位置状态或过程触发条件。

数字信号输出控制(DO)

输出控制信号至执行器件,如继电器、气动阀、电磁锁、指示灯等;

用于设备动作控制、状态反馈或安全联锁输出。

状态监测与逻辑控制

配合主控制器(PLC/嵌入式系统)实现流程逻辑、故障响应、自动切换等任务。

通信与同步

通过背板总线或专用控制总线与主控系统进行通信,参与多模块同步运行。

三、典型应用领域

| 应用设备 | 控制任务 |

|---|---|

| Etcher(干法刻蚀) | 控制气阀开关、等离子体启停、安全门状态检测等 |

| CVD/ALD设备 | 管理气体供给阀、电源联锁、温控系统启停 |

| 光刻涂胶设备(Track) | 控制晶圆传输动作、烘烤单元门控、显影流程逻辑 |

| 晶圆搬运系统 | 检测机械臂到位、真空吸附、托盘状态等信号 |

英文资料:

The TEL Tokyo Electron EC81-000053-11 Digital I/O Control Board is one of the key control modules used in TEL semiconductor equipment, responsible for processing and executing control tasks for digital input/output signals. This board is widely deployed in multiple core equipment systems of TEL, especially for performing mechanical linkage, equipment status monitoring, safety interlocking, and process logic control.

1、 Basic Information

Product Name: Digital Control Board

Product model: EC81-000053-11

Manufacturer: Tokyo Electron Ltd. (TEL)

Board type: Digital I/O Board

Deployment location: In the equipment control cabinet or module control system

2、 Main functions

Digital Signal Input Processing (DI)

Receive switch signals from external devices such as sensors, limit switches, buttons, relays, etc;

Determine the operational status, physical location status, or process triggering conditions of the equipment.

Digital Signal Output Control (DO)

Output control signals to actuators such as relays, pneumatic valves, electromagnetic locks, indicator lights, etc;

Used for equipment action control, status feedback, or safety interlock output.

State monitoring and logic control

Collaborate with the main controller (PLC/embedded system) to implement tasks such as process logic, fault response, and automatic switching.

Communication and synchronization

Communicate with the main control system through the backplane bus or dedicated control bus to participate in synchronous operation of multiple modules.

3、 Typical application areas

Application device control tasks

Etcher (dry etching) control valve switch, plasma start stop, safety door status detection, etc

CVD/ALD equipment management gas supply valve, power interlock, temperature control system start stop

Photolithography coating equipment (Track) controls wafer transfer actions, baking unit gate control, and development process logic

The wafer handling system detects signals such as the arrival of the robotic arm, vacuum suction, and tray status

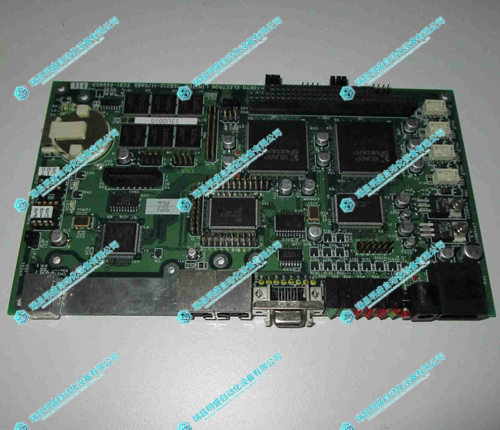

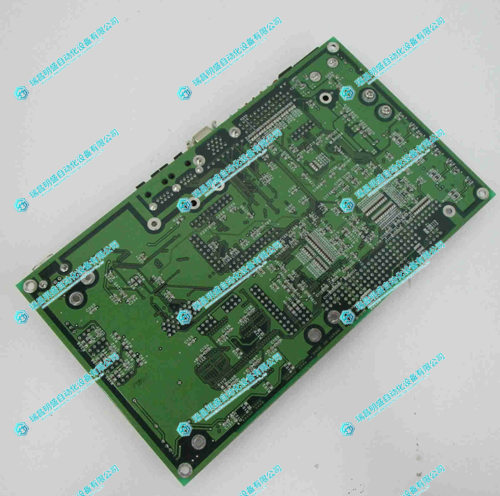

2.产 品 展 示

3.其他产品

4.其他英文产品

Radisys ATCA-PP81 controller module

AMAT 0190-24282 encoder module

IC3600EPSS1B power supply boar

| PPM-3 | HONEYWELL CC-TCF901 | 170M6467 3AUA0000062487 |

| PPC-IPC-S | GENERA G2010 A 10.4ST | 6DD2920-0AM0 |

| PP881 3BSE094354L1 | TVB3101-1/ISC | 6DD2920-0AR5 |

| PP875 3BSE092977R1 | AP-1031D ID01050A | SDCS-FEX-4 3ADT314500R1001 |

| PMB33F-20216-02 | IS420ESWBH3A | 6DD2920-0BB0 |

| PMB33F-20216-01 | DAI03 | 07KT98 GJR5253100R0160 |

| PMB33F-20216-00 | PM862K01 3BSE076940R1 | YPH107A 3ASD579001A9 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218