TEL Tokyo Electron 408-500111-3自动装载机板

1.产 品 资 料 介 绍:

中文资料:

TEL Tokyo Electron 408-500111-3 自动装载机板 是东京电子(TEL)半导体制造设备中用于控制晶圆自动装载/卸载装置的专用控制电路板。该板卡通常安装于前端装载系统(Front-End Module, FEM)或自动化搬运系统中,实现晶圆盒(FOUP/SMIF)与工艺舱室之间的高精度传送。

一、产品概述

| 项目 | 内容 |

|---|---|

| 产品名称 | 自动装载机板(Auto Loader Board) |

| 产品型号 | 408-500111-3 |

| 制造厂商 | Tokyo Electron Ltd.(东京电子) |

| 安装位置 | 晶圆自动搬运系统/前端模块控制单元内部 |

| 功能定位 | 晶圆装载与卸载机构的控制与状态管理 |

二、核心功能

自动装载控制

控制机械臂、升降平台、真空吸附系统等完成晶圆自动装载动作;

管理晶圆盒对接、舱门开启/关闭、Wafer对准等精细动作。

动作信号输出与反馈采集

输出多路驱动信号,驱动步进电机或伺服系统执行搬运动作;

采集传感器反馈,如位置传感器、对位传感器、门禁状态等。

状态监测与异常处理

实时监控自动装载系统工作状态,支持中断、报警与自诊断功能;

保障晶圆搬运过程的可靠性与安全性。

三、典型应用领域

TEL 涂胶显影机(Coater/Developer):自动装载晶圆至旋涂/显影腔体;

蚀刻设备(Etcher)、清洗设备(Cleaner):控制晶圆从前端到腔体的精密转移;

前端模块(FEM) 与 中控系统 的连接桥梁。

英文资料:

The TEL Tokyo Electron 408-500111-3 automatic loader board is a dedicated control circuit board used in the semiconductor manufacturing equipment of Tokyo Electronics (TEL) to control the automatic wafer loading/unloading device. This board is usually installed in the Front End Module (FEM) or automated handling system to achieve high-precision transfer between the wafer box (FOUP/SMIF) and the process compartment.

1、 Product Overview

Project Content

Product Name: Auto Loader Board

Product model 408-500111-3

Manufacturer Tokyo Electron Ltd

Installation location: Inside the wafer automatic handling system/front-end module control unit

Control and status management of functional positioning wafer loading and unloading mechanism

2、 Core functions

Automatic loading control

Control the robotic arm, lifting platform, vacuum adsorption system, etc. to complete the automatic wafer loading action;

Manage precise actions such as docking of crystal round boxes, opening/closing of cabin doors, and alignment of wafers.

Action signal output and feedback acquisition

Output multiple drive signals to drive stepper motors or servo systems to perform handling actions;

Collect sensor feedback, such as position sensors, alignment sensors, access control status, etc.

Status monitoring and exception handling

Real time monitoring of the working status of the automatic loading system, supporting interrupt, alarm, and self diagnostic functions;

Ensure the reliability and safety of the wafer handling process.

3、 Typical application areas

TEL Coater/Developer: Automatically loads wafers into spin coating/development chambers;

Etcher and Cleaner: Control the precise transfer of wafers from the front end to the cavity;

The connection bridge between the front-end module (FEM) and the central control system.

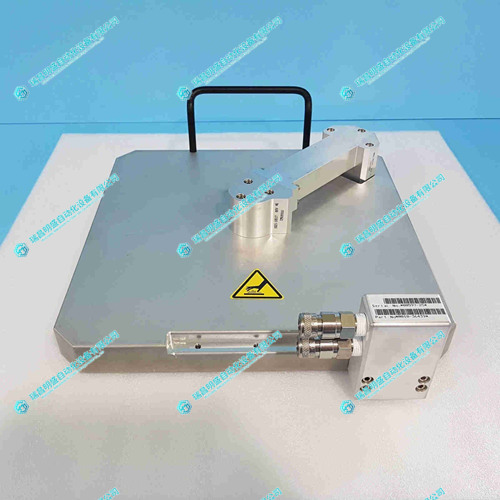

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA YB161102-AK Robot Computer Board

| R46GENA-T2-NS-NV-02 | R34JENT-TS-LA-NV-01 | R43HENA-TS-NF-NV-00 |

| R46GENA-R2-NS-NV-00 | R32GENC-HS-ND-NV-00 | S33HSNA-RNNM-02 |

| R46GENA-R2-NG-VS-00 | R46GSNA-HS-NS-NV-03 | S31GNAA-RNNM-00 |

| R46GENA-HS-NS-NV-00 | R33GENT-TS-NS-NV-00 | R43GENA-R2-NS-NV-00 |

| R46GEBA-R2-NS-VS-00 | R45GENA-R2-NS-NV-00 | S21HNNA-RNN6-00 |

| R46GEBA-R2-NS-NV-02 | R22H5NA-R1-NS-NV-17 | R24SSNA-R1-NS-NV-03 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218