AMAT Applied Materials 0100-18043插槽背板

1.产 品 资 料 介 绍:

AMAT Applied Materials 0100-18043插槽背板 英文资料:

1. High-density multi-interface expansion capability

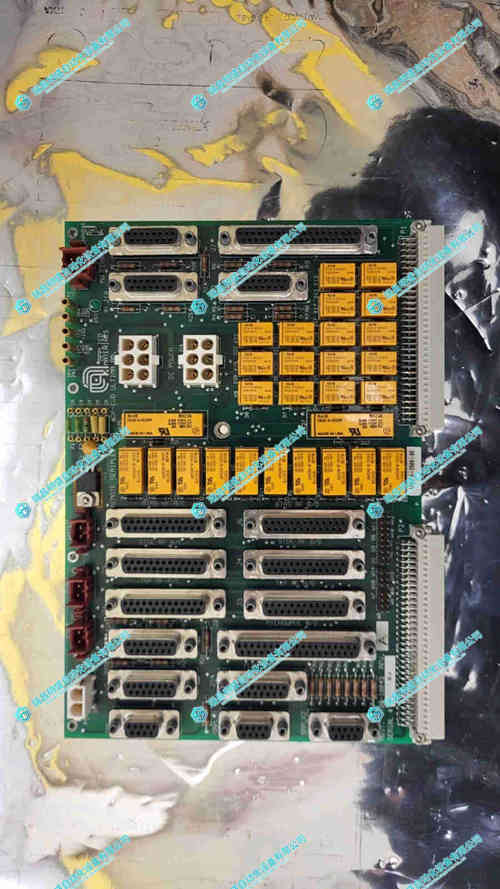

As the core hub for circuit interconnection of semiconductor equipment, the core advantage of the 0100-18043 slot backplane lies in its compatibility with all types of modules and interface expansion performance. Referring to the modular integration requirements of AMAT devices, this backplane is likely to adopt a 16-24 standardized slot design, compatible with multiple types of boards such as digital I/O boards (like 0100-20003), controller modules, power modules, etc. A single slot supports high-speed protocols such as PCIe Gen6 and EtherCAT. At the same time, traditional industrial bus interfaces such as RS485 and CANopen are reserved to meet the interconnection requirements of different functional modules in etching machines and thin film deposition equipment. The slot spacing strictly adheres to the 3U/6U standard board card specifications. Each slot has a power supply capacity of up to 300W, which can directly provide stable power to high-power modules without the need for additional independent power supplies, effectively simplifying the internal circuit layout of the equipment.

2. High-speed signal synchronous transmission capability

In response to the strict requirements of semiconductor equipment for signal real-time performance, the backplane of this slot highlights low latency and anti-interference characteristics in signal processing. By adopting a layered grounding and differential signal wiring design, the power layer, ground layer and signal layer are alternately arranged. Combined with impedance matching technology (characteristic impedance control accuracy ±5%), the transmission delay of PCIe Gen6 signals is controlled within 5ns, and the communication cycle of EtherCAT is stably maintained at 125μs. Ensure the distortion-free synchronous transmission of the RF control signals and sensor data of the etching machine. The backplane is equipped with an internal signal relay amplification module. Each signal is provided with an independent signal conditioning circuit, which can compensate for signal attenuation caused by multi-module cascading. It supports 8-level module expansion while maintaining signal integrity, meeting the multi-module collaborative control requirements of large semiconductor equipment.

Iii. Specialized Adaptation design for Harsh Environments

To address the complex working conditions of semiconductor cleanrooms and equipment clusters, the backplane is designed with full consideration of anti-interference and clean compatibility capabilities in its hardware. The substrate adopts Megtron 7 high-performance laminate, which combines low dielectric loss (Df≤0.002@10GHz) and high thermal conductivity. Combined with grid copper cladding and embedded resistor technology, the temperature rise during full-load operation is reduced by 35% compared with the traditional FR-4 substrate. The surface adopts the chemical gold precipitation process, and the precipitation amount of metal ions is less than 0.05ppm, which complies with the SEMI F57 standard and is suitable for a Class 10 cleanroom environment. The casing is made of 316L stainless steel shielding frame, with an electromagnetic interference suppression capacity of over 120dB, which can resist the strong electromagnetic radiation generated by the RF power supply of the etching machine and prevent equipment maloperation caused by signal crosstalk. It has simultaneously passed the IP65-level protection certification, withstanding a wide temperature range of -30 ℃ to 70℃ and a high humidity environment of 90% RH, meeting the environmental differences of factories in different regions.

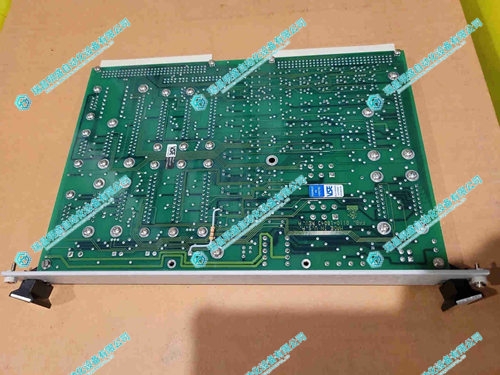

AMAT Applied Materials 0100-18043插槽背板 产品展示

产品视频

3.其他产品

IS420PUAAH1A 控制器模块

PM645B 处理器模块

WOODWARD 8273-140 速度控制器

4.其他英文产品

UNS3670A-Z,V2 HIEE205011R0002 Excitation card

YASKAWA CACR-02-TE1K Driver module

EATON MPB1-TP Spare parts module

| S33GNAA-RNNM-00 | SC725B001 | SCE905-001-01A |

| S33GMNA-RNNM-00 | SC452-033-03 | SCE905AN-002-01 |

| S33ANNH-RNUM-00 | SC725A-001-PM72003 | SCE905NN-000-01 |

| S32HSNA-RNNM-03 | SC452-013-05 | SCE905-001-01 |

| S32HNNA-RNNM-00 | SC723A-001 | SCE903-001-01 |

| S32HNNA-HGVM-00 | SC726A-001-PM72009 | SCE904-002-01 A |

| S32HMAA-HNNM-03 | SC453-016-02 | SC904AN-046-01 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218