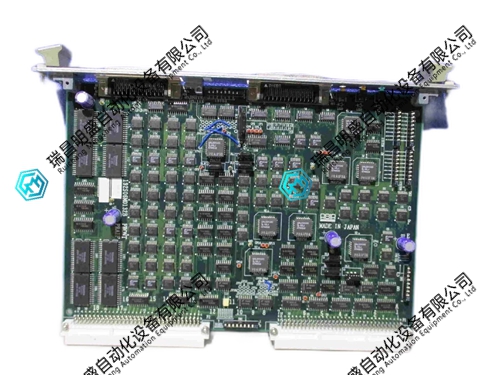

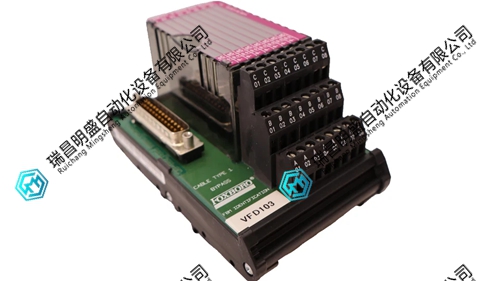

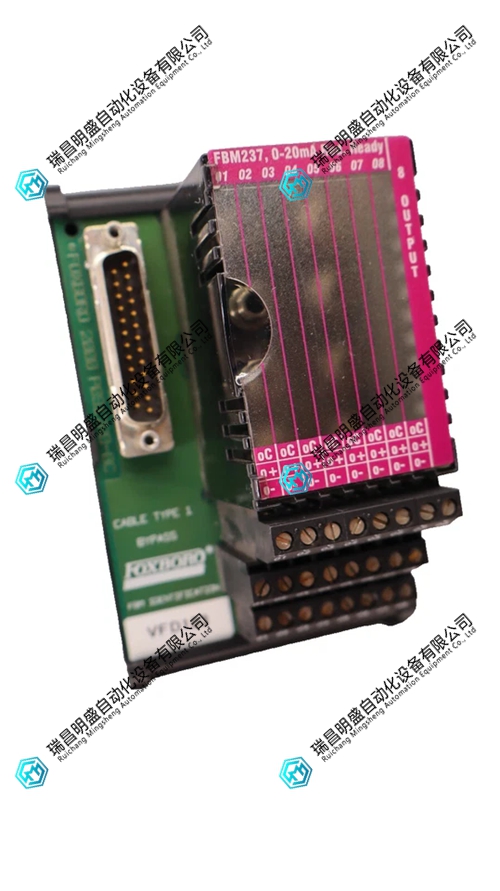

1.产 品 资 料 介 绍:

FBM237-P0917QZ输出模块为Foxboro I/A系列模拟输出模块,具备8通道独立隔离设计,支持4-20mA直流模拟输出与冗余配置,耐受-20℃至+70℃宽温及恶劣工业环境,兼容HART协议,可精准驱动执行机构,实现过程参数闭环控制,适配多行业自动化场景,具体应用如下:

1. 石油化工精馏装置:输出精准电流信号控制调节阀开度,调节物料流量与温度,依托冗余设计保障连续生产。

2. 火力发电锅炉系统:驱动给水调节阀、引风机执行机构,精准调控水位与风量,适配电厂高可靠性需求。

3. 城市污水处理厂:控制曝气阀、加药泵运行,根据水质参数动态调节输出,优化污水处理效率。

4. 制药行业反应釜:按工艺曲线调节搅拌转速与冷却阀开度,符合GMP规范,保障批次生产一致性。

5. 冶金连铸生产线:驱动结晶器液位调节阀,精准控制钢水液位,适配高温强干扰工业环境。

6. 食品饮料灌装线:控制流量调节阀与灌装阀,实现定量灌装,依托高精度输出保障产品规格统一。

7. 天然气长输管线:调节压力调节阀与截断阀,实时响应压力变化,保障管线输送安全稳定。

8. 水泥回转窑系统:驱动喂料机与喷煤量执行机构,调控窑内温度与物料配比,降低能耗。

9. 半导体洁净车间:控制新风阀与压力调节阀,维持车间恒温恒压,适配洁净度管控需求。

10. 海水淡化设备:调节反渗透膜压力调节阀,优化产水效率,耐受高盐雾腐蚀环境。

11. 橡胶硫化生产线:控制蒸汽阀与液压执行机构,精准调控硫化温度与压力,提升产品质量。

12. 城市集中供热管网:调节换热站供水调节阀,根据室外温度动态调整供热量,实现节能运行。

13. 锂电池材料搅拌设备:控制搅拌电机转速与进料阀,保障物料混合均匀度,适配锂电生产工况。

14. 工业窑炉温控系统:驱动燃气调节阀,按升温曲线精准控制炉内温度,适配高温工业场景。

15. 矿山浮选车间:调节药剂添加泵与浮选机液位阀,优化矿物浮选效率,耐受粉尘干扰环境。

注:产品核心优势为多通道隔离、冗余容错与高环境适应性,支持故障安全动作配置,兼容Foxboro DCS系统,适配各类工业过程闭环控制需求。

FBM237-P0917QZ输出模块 英文资料:

The FBM237-P0917QZ output module is a Foxboro I/A series analog output module with an 8-channel independent isolation design. It supports 4-20mA DC analog output and redundant configuration, and can withstand a wide temperature range of -20 ℃ to+70 ℃ and harsh industrial environments. It is compatible with the HART protocol and can accurately drive actuators to achieve closed-loop control of process parameters. It is suitable for automation scenarios in multiple industries. The specific applications are as follows:

1. Petrochemical distillation unit: Output precise current signals to control the opening of regulating valves, adjust material flow and temperature, and rely on redundant design to ensure continuous production.

2. Thermal power boiler system: Drive the feedwater control valve and induced draft fan actuator to accurately regulate the water level and air volume, adapting to the high reliability requirements of power plants.

3. Urban sewage treatment plant: Control the operation of aeration valves and dosing pumps, dynamically adjust the output according to water quality parameters, and optimize sewage treatment efficiency.

4. Pharmaceutical industry reaction kettle: Adjust the stirring speed and cooling valve opening according to the process curve to comply with GMP standards and ensure batch production consistency.

5. Metallurgical continuous casting production line: Drive the crystallizer liquid level regulating valve, accurately control the liquid level of molten steel, and adapt to high temperature and strong interference industrial environments.

6. Food and beverage filling line: Control the flow regulating valve and filling valve to achieve quantitative filling, relying on high-precision output to ensure uniform product specifications.

7. Natural gas long-distance pipelines: Adjust pressure regulating valves and shut-off valves to respond in real-time to pressure changes, ensuring safe and stable pipeline transportation.

8. Cement rotary kiln system: drives the feeder and coal injection actuator to regulate the temperature and material ratio inside the kiln, reducing energy consumption.

9. Semiconductor clean room: Control the fresh air valve and pressure regulating valve to maintain constant temperature and pressure in the workshop, and adapt to the requirements of cleanliness control.

10. Seawater desalination equipment: Adjust the pressure regulating valve of the reverse osmosis membrane to optimize water production efficiency and withstand high salt spray corrosion environments.

11. Rubber vulcanization production line: Control steam valves and hydraulic actuators, accurately regulate vulcanization temperature and pressure, and improve product quality.

12. Urban centralized heating pipeline network: Adjust the water supply regulating valve of the heat exchange station, dynamically adjust the heating amount according to the outdoor temperature, and achieve energy-saving operation.

13. Lithium battery material mixing equipment: Control the speed of the mixing motor and the feeding valve to ensure the uniformity of material mixing and adapt to the production conditions of lithium batteries.

14. Industrial kiln temperature control system: Drive the gas regulating valve to accurately control the temperature inside the furnace according to the heating curve, suitable for high-temperature industrial scenarios.

15. Mining flotation workshop: Adjust the reagent addition pump and flotation machine level valve to optimize mineral flotation efficiency and withstand dust interference environment.

Note: The core advantages of the product are multi-channel isolation, redundant fault tolerance, and high environmental adaptability. It supports fault safe action configuration, is compatible with Foxboro DCS system, and adapts to various industrial process closed-loop control requirements.

FBM237-P0917QZ输出模块 产品展示

产品视频

3.其他产品

Siemens 193-1CL00-0XA0 数字输出模块

A-B 1747-ASBPLC模块

HONEYWELL 8C-PCNT01 51454363-175扩展模块

4.其他英文产品

IS210AEBIH3BED Gas Turbine Safety Board

Honeywell 5119929-100 processor module

UNIOP EKDC-16-6ZA933-7 Display Module

| 4199J51-G01 | SSIV-21 | 57310255-A DSRF150 ABB |

| 4179J51-G01 | SS950-20000 | PFEA111-65 3BSE050090R65 |

| 4176J86-G01 | HG109A6 | PFEA 111, IP 65 |

| 4161J28-G03 | HZ40S202A6 | PFCL 201CD-10.0KN |

| 4145J42G1 | HM408A6 | 57160001-TZ DSTD110A ABB |

| 4145J42-G01 | P81010Z1200002 | PFCL 201CE-5.0KN |

| 4136J63G1 | HG96A603 | TRICONEX 3664 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218