1.产 品 资 料 介 绍:

FBM242-P0916JY外置开关模块为Foxboro I/A Series DCS系统专用离散量输入模块,具备16通道干触点信号采集、全通道电气隔离功能,支持-40℃至+85℃宽温工作与IP67防护等级,可精准接收现场传感器信号并传输至控制系统,适配恶劣工业环境下的离散控制与状态监测需求,具体应用如下:

1. 石油化工储罐区:采集储罐液位开关、紧急切断阀状态信号,联动安全联锁系统,保障储运安全。

2. 火力发电汽轮机室:监测阀门开度限位开关、轴承振动传感器信号,实时反馈设备运行状态,支撑故障预警。

3. 汽车焊装生产线:接收工装夹具定位开关、焊枪到位信号,联动控制焊接流程,保障工位精准衔接。

4. 城市给排水泵站:采集水泵启停状态、止回阀开关信号,上传至管控平台,实现泵站自动化运维。

5. 冶金高炉上料系统:监测料仓料位开关、皮带跑偏传感器信号,调控上料节奏,防范物料溢出风险。

6. 制药洁净车间:接收门窗密封开关、压差传感器信号,符合GMP规范,保障车间洁净度与密封性。

7. 天然气处理厂:采集过滤器压差开关、安全阀状态信号,实时反馈设备工况,支撑工艺优化。

8. 智能仓储分拣线:接收货物到位开关、分拣机构限位信号,联动AGV调度,实现自动化分拣流转。

9. 水泥厂熟料库:监测库顶除尘器启停开关、料位报警开关信号,保障熟料储存与输送稳定。

10. 污水处理格栅间:采集格栅机运行状态、过载保护开关信号,自动调控清污节奏,防范设备损坏。

11. 半导体晶圆厂:接收光刻机工位定位开关、真空度检测信号,精准反馈设备运行状态,保障制程稳定。

12. 矿山井下运输系统:监测矿车到位开关、轨道道岔状态信号,适配高粉尘环境,保障运输安全。

13. 食品加工包装车间:采集包装膜张力开关、成品检测开关信号,调控包装流程,保障产品合格率。

14. 轨道交通车辆段:监测列车制动状态开关、车门限位信号,上传至调度系统,支撑车辆运维管控。

15. 光伏电站逆变器室:采集逆变器启停状态、冷却风扇运行开关信号,实时监测设备工况,保障发电稳定。

注:产品核心优势为高防护等级、全通道隔离与宽温适应性,兼容Foxboro I/A系列DCS,支持在线诊断,适配各类工业离散控制与状态监测场景。

FBM242-P0916JY外置开关模块 英文资料:

The FBM242-P0916JY external switch module is a specialized discrete input module for Foxboro I/A Series DCS systems, with 16 channel dry contact signal acquisition and full channel electrical isolation functions. It supports wide temperature operation from -40 ℃ to+85 ℃ and IP67 protection level. It can accurately receive on-site sensor signals and transmit them to the control system, adapting to the discrete control and status monitoring needs in harsh industrial environments. The specific applications are as follows:

1. Petrochemical tank area: Collect tank level switch and emergency shut-off valve status signals, link safety interlock system to ensure storage and transportation safety.

2. Thermal power generation turbine room: Monitor valve opening limit switches, bearing vibration sensor signals, provide real-time feedback on equipment operating status, and support fault warning.

3. Automotive welding production line: receiving fixture positioning switches and welding gun positioning signals, linking and controlling the welding process to ensure precise connection between workstations.

4. Urban water supply and drainage pump station: Collect the start stop status and check valve switch signals of the pump, upload them to the control platform, and achieve automated operation and maintenance of the pump station.

5. Metallurgical blast furnace feeding system: Monitor the level switch of the silo and the signal of the belt deviation sensor, regulate the feeding rhythm, and prevent the risk of material overflow.

6. Pharmaceutical cleanroom: Receive signals from door and window sealing switches and differential pressure sensors, in compliance with GMP standards, to ensure the cleanliness and sealing of the workshop.

7. Natural gas processing plant: Collect filter differential pressure switch and safety valve status signals, provide real-time feedback on equipment operating conditions, and support process optimization.

8. Intelligent warehouse sorting line: receives goods arrival switch, sorting mechanism limit signal, links AGV scheduling, and realizes automated sorting flow.

9. Cement plant clinker warehouse: Monitor the start stop switch of the dust collector on the top of the warehouse and the level alarm switch signal to ensure stable storage and transportation of clinker.

10. Sewage treatment grid room: Collect the operating status of the grid machine, overload protection switch signals, automatically adjust the cleaning rhythm, and prevent equipment damage.

11. Semiconductor wafer fab: Receive positioning switches and vacuum detection signals from lithography machine workstations, accurately feedback equipment operating status, and ensure process stability.

12. Underground transportation system in mines: Monitor the status signals of the mine car's in place switch and track switch, adapt to high dust environments, and ensure transportation safety.

13. Food processing and packaging workshop: Collect signals from packaging film tension switches and finished product detection switches, regulate packaging processes, and ensure product qualification rates.

14. Rail Transit Vehicle Depot: Monitor train braking status switches and door limit signals, upload them to the dispatch system, and support vehicle operation and maintenance control.

15. Photovoltaic power station inverter room: Collect the start stop status of the inverter and the operation switch signal of the cooling fan, monitor the equipment working conditions in real time, and ensure stable power generation.

Note: The core advantages of the product are high protection level, full channel isolation, and wide temperature adaptability. It is compatible with Foxboro I/A series DCS, supports online diagnosis, and is suitable for various industrial discrete control and status monitoring scenarios.

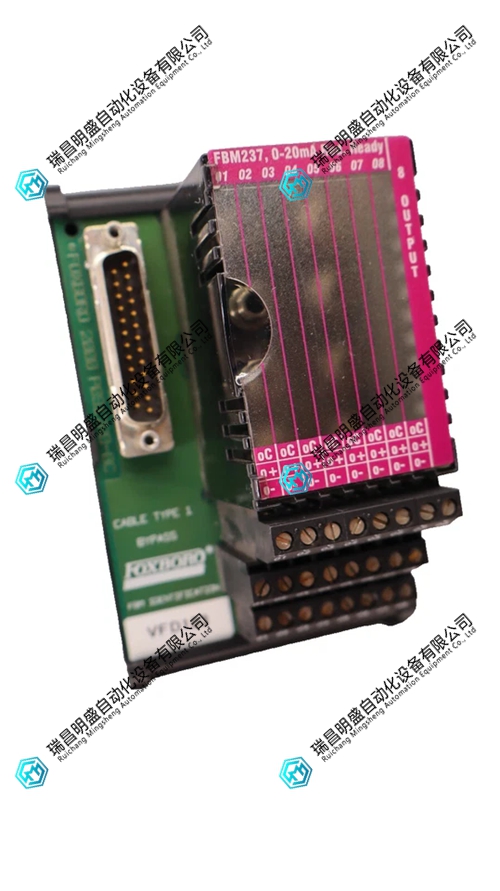

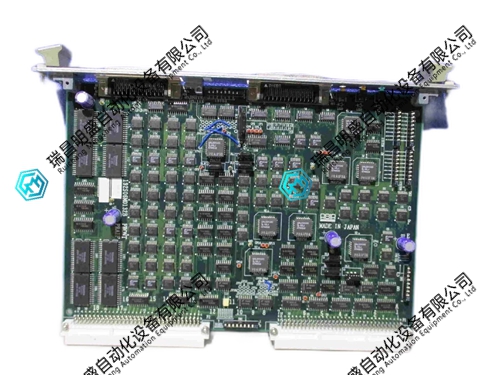

FBM242-P0916JY外置开关模块 产品展示

产品视频

3.其他产品

A-B 1747-ASBPLC模块

HONEYWELL 8C-PCNT01 51454363-175扩展模块

MECS CS-1000 UTX1700PTFE气体吸收器

4.其他英文产品

Honeywell 5119929-100 processor module

UNIOP EKDC-16-6ZA933-7 Display Module

B&R X20AIB744 Analog Input Module

| 4136J63-G01 | SS7PG-48BMC | IMDSI22 |

| 40PA60-36-37-TEFC-G | HG932A6 | IMDSM04 |

| 40PA59-55-TEFC-S | 193X735ACG01 | 067-10098-0000 |

| 40PA58-53-TEFC-S | PRD-SC30000Z-41 | 0AF00 |

| 40PA57-36-37-TENV-S | SS2000MD7-RC | 6ES5306-7LA11 |

| 40PA56-55-TEFC-G | SS2000MD4-101 | 53575-00001-C |

| 40PA54-36-37-TEFC-S | 51350-60 | SH845GV |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218