1.产 品 资 料 介 绍:

192S06M0132B控制系统模块应用领域

192S06M0132B控制系统模块具备模块化集成、快速组网适配及精准闭环控制能力,支持信号采集与执行指令联动,兼容多种传感器与执行器,适配离散制造、智能装备及特种场景的管控需求,具体应用如下:

1. 智能仓储物流:管控AGV机器人路径规划与分拣设备,联动货架调度,实现仓储自动化流转。

2. 半导体制造设备:适配晶圆刻蚀、封装设备,精准控制机械臂动作与工艺气体流量。

3. 锂电生产流水线:管控电芯涂布、卷绕工序,实时调节压力、速度参数,保障电芯一致性。

4. 智能温室种植:联动温湿度、光照传感器,自动控制遮阳、灌溉、通风设备,调控生长环境。

5. 工业烤箱温控:实现多段式温度曲线控制,适配电子元件、五金件烘烤工艺,保障温控精度。

6. 轨道交通信号控制:用于站台屏蔽门、道岔控制模块,实现信号联动与安全联锁。

7. 光伏组件检测设备:管控EL检测仪、功率测试仪,联动传输线实现组件质量自动化筛查。

8. 包装机械控制:适配灌装、封膜、贴标设备,调节运行节拍,保障包装精度与效率。

9. 冷链冷库管控:联动制冷机组与温感节点,实现分区温控与超温报警,留存运行数据。

10. 机器人焊接工作站:控制焊接机器人运动轨迹与焊接参数,适配汽车零部件、钢结构焊接。

11. 智能楼宇自控:管控中央空调、新风系统,联动消防信号,实现能耗优化与应急调控。

12. 试验台测控系统:适配汽车、航空零部件试验台,采集力学、电学参数并闭环调控。

13. 垃圾焚烧处理:管控焚烧炉进料、鼓风系统,调节燃烧工况,降低有害气体排放。

14. 电子制造SMT设备:控制贴片机、回流焊炉,联动物料输送,保障贴片精度与焊接质量。

15. 特种车辆控制系统:适配工程车、环卫车,管控动力输出与作业装置,提升操作安全性。

注:产品核心优势为模块化设计、快速组网与高精度闭环控制,支持定制化信号适配,适配离散制造与特种管控场景。

192S06M0132B控制系统模块 英文资料:

192S06M0132B Control System Module Application Fields

The 192S06M0132B control system module has modular integration, fast networking adaptation, and precise closed-loop control capabilities. It supports signal acquisition and command execution linkage, is compatible with multiple sensors and actuators, and adapts to the control requirements of discrete manufacturing, intelligent equipment, and special scenarios. The specific applications are as follows:

1. Intelligent warehousing logistics: Manage AGV robot path planning and sorting equipment, coordinate shelf scheduling, and achieve automated warehousing circulation.

2. Semiconductor manufacturing equipment: adapted to wafer etching and packaging equipment, precise control of robotic arm movements and process gas flow.

3. Lithium battery production line: Control the coating and winding processes of battery cells, adjust pressure and speed parameters in real time, and ensure the consistency of battery cells.

4. Intelligent greenhouse planting: linked with temperature, humidity, and light sensors, automatically controlling shading, irrigation, and ventilation equipment, and regulating the growth environment.

5. Industrial oven temperature control: achieve multi-stage temperature curve control, adapt to electronic components and hardware baking processes, and ensure temperature control accuracy.

6. Rail transit signal control: used for platform screen doors and switch control modules to achieve signal linkage and safety interlocking.

7. Photovoltaic module testing equipment: Control EL detectors, power testers, and link transmission lines to achieve automated screening of module quality.

8. Packaging machinery control: adapted to filling, sealing, and labeling equipment, adjusting the operating cycle to ensure packaging accuracy and efficiency.

9. Cold chain cold storage control: Link refrigeration units with temperature sensing nodes to achieve zone temperature control and over temperature alarm, and retain operational data.

10. Robot welding workstation: controls the motion trajectory and welding parameters of the welding robot, and is suitable for welding automotive parts and steel structures.

11. Intelligent building automation: Control central air conditioning and fresh air systems, link fire signals, achieve energy optimization and emergency regulation.

12. Test bench measurement and control system: adapted to automotive and aviation component test benches, collecting mechanical and electrical parameters and closed-loop control.

13. Garbage incineration treatment: Control the feeding and blowing system of the incinerator, adjust the combustion conditions, and reduce harmful gas emissions.

14. Electronic manufacturing SMT equipment: controls the surface mount machine, reflow soldering furnace, and links material transportation to ensure surface mount accuracy and welding quality.

15. Special vehicle control system: adapted to engineering vehicles and sanitation vehicles, controls power output and operating devices, and enhances operational safety.

Note: The core advantages of the product are modular design, fast networking, and high-precision closed-loop control, supporting customized signal adaptation, and adapting to discrete manufacturing and special control scenarios.

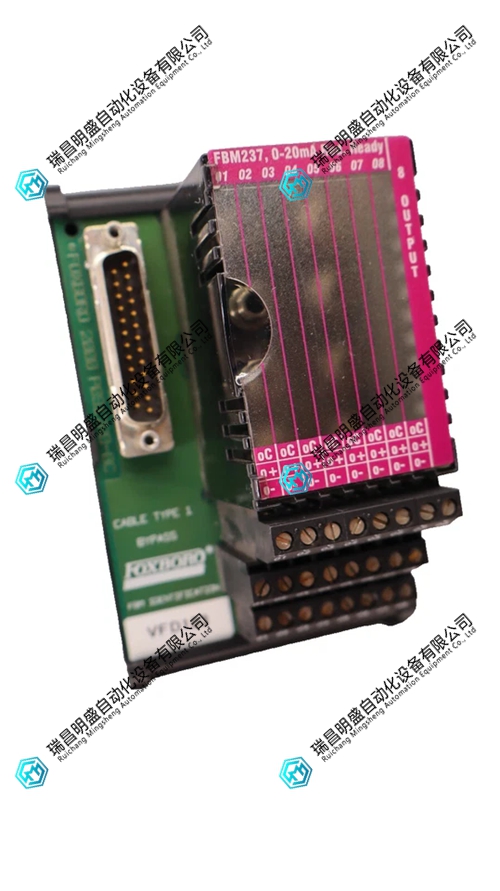

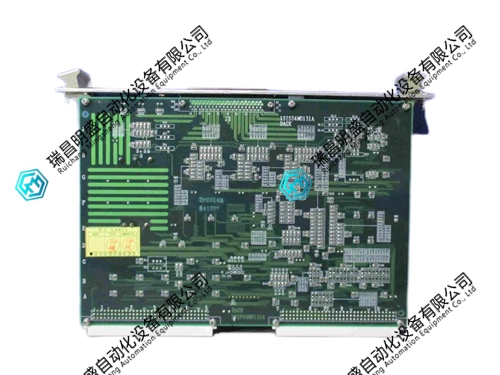

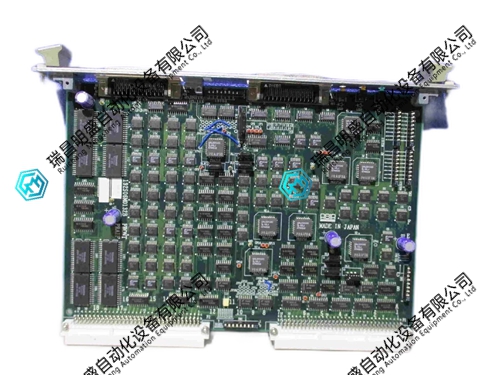

192S06M0132B控制系统模块 产品展示

产品视频

3.其他产品

TRICONEX 3604E控制器

ICS TRIPLEX T8193模块化控制系统

Siemens 193-1CL00-0XA0 数字输出模块

4.其他英文产品

RELIANCE 57C328 Remote I/O Network Interface Module

KOLLMORGEN S70601-SE Digital Output Module

HONEYWELL CC-TUIO31 I/O Module

| 489-P5-LO-A20-E | HP59A60192 | IC3600SVDC1C |

| 489-P5-LO-A20 | HLLA-1 | IC3600SVDC1 |

| 489-P5-HI-A20-T-H | HZ171A601 | IC3600SVDB1 |

| 489-P5-HI-A20-T | HP56A60192 | IC3600SVDA1B |

| 489-P5-HI-A20-E-H | SS7-35B | IC3600TPAE1B |

| 489-P5-HI-A20-E | PSR45A-275 | IC3600TPAB1B |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218