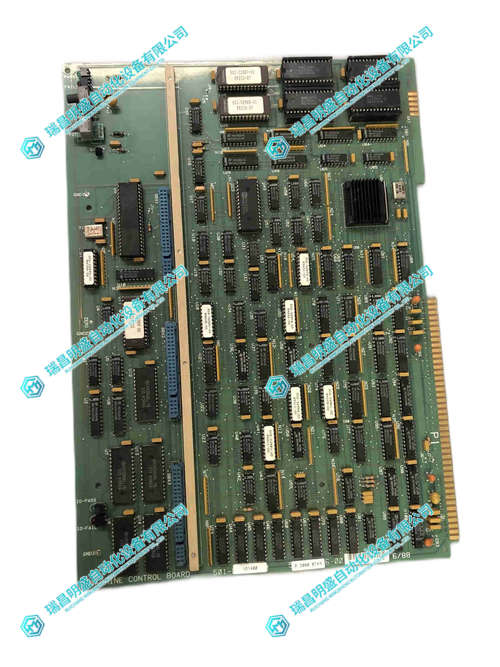

GIDDINGS & LEWIS 501-101400机器控制板

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 501-101400 机器控制板详解

一、核心功能:设备运行的 "总调度中心"

二、技术特点:支撑高效控制的关键性能

英文资料:

GIDINGS&LEWIS 501-101400 Machine Control Board Detailed Explanation

1、 Core Function: The 'General Dispatch Center' for device operation

The GIDINGS&LEWIS 501-101400 machine control board serves as the core control module for industrial automation and CNC equipment, playing the role of the "overall dispatcher". After receiving instructions from the upper controller, it coordinates the actions of various execution units such as servo drives, stepper motors, hydraulic valves, etc. through precise signal conversion and distribution. At the same time, it integrates motion control and logic control functions to ensure that each link of the machine tool or automation equipment runs in sequence and synchronously. It is the core hub for efficient and precise operation of complex industrial systems.

2、 Technical features: Key performance supporting efficient control

Multi control capability: supports multiple modes such as pulse output, direction control, and logic execution control, and can adapt to different types of actuators. For example, the displacement accuracy of the feed axis is controlled by pulse signals, the rotation direction of the spindle is adjusted by direction signals, and the linkage of auxiliary equipment is achieved through logic control to meet the diverse control needs of complex equipment.

Flexible interface configuration: The input interface can receive instruction signals from the CPU or logic controller, and the output interface can drive multiple execution mechanisms. It can be directly connected to servo drives, relays, and other devices, and can also increase control channels through expansion modules to adapt to different scenarios from single devices to multi unit linkage.

Industrial grade signal compatibility: Compatible with industrial standard levels such as 24VDC, ensuring seamless signal integration with upstream and downstream devices (such as sensors and actuators), avoiding signal transmission errors or equipment damage caused by level mismatch, and improving system compatibility.

High speed response and synchronization: Equipped with high-speed pulse output capability, supporting multi axis synchronous control, and response delay controlled within milliseconds. In multi axis linkage equipment, it is possible to ensure that the time difference between the actions of each axis is controlled within a very small range. For example, in the X and Y axis linkage of CNC machine tools, high-precision linear or circular interpolation can be achieved.

Comprehensive protection mechanism: integrated overload, short circuit, overvoltage, and signal abnormality protection functions. When overload of the actuator, short circuit of the circuit, or abnormal power supply voltage is detected, the output signal will be immediately cut off and an alarm will be triggered to protect the control board and downstream equipment from damage and reduce fault losses.

Advantages of modular design: Adopting a plug-in card design, it can be directly installed in cabinets or racks, and installation and replacement do not require dismantling the entire control system. When upgrading or maintaining equipment, simply plug and unplug modules to complete the operation, greatly reducing downtime and improving system maintainability.

Intuitive status monitoring: Real time display of the working status of each control channel (such as normal operation, fault, standby) through LED indicator lights. Technicians can quickly determine whether signal transmission is normal, shorten troubleshooting time, and improve debugging and maintenance efficiency.

2.产 品 展 示

3.其他产品

4.其他英文产品

DEIF LSU-113DG voltage regulator

AFP9075355 3BHS537443 voltage regulator

| PMB31B-00114-01 | AMAT 0100-01488 | PFTL201C 50.0KN |

| PMB31B-00114-00 | AMAT 0100-03133 | PFTL201C |

| PMB31B-00101-03 | 07EB200 | N32HLHJ-LNK-NS-00 |

| PMB31B-00101-02 | NPSI02 | 57120001-HE DSAI 309 |

| PMB31B-00101-01 | NKAS11 | P21NSXS-LSS-NS-05 |

| PMB31B-00101-00 | AMAT 0100-91085 | PFTL101AER 2.0KN 3BSE023012R1 |

| PMB31B-00100-00 | INBIM02 | 57160001-PA DSDI 116 |

Contact: +86 15270269218