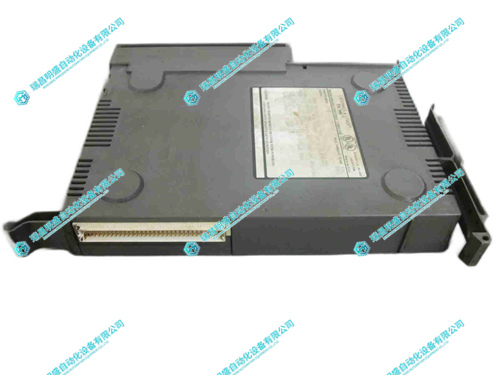

GIDINGS&LEWIS 502-03551-02交流电输入输出模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 502-03551-02 交流电输入输出模块产品特点解析

一、多通道交流输入输出:适配多设备协同需求

二、高精度信号处理:保障设备动作精准同步

三、高速响应:满足高速生产动态需求

英文资料:

GIDINGS&LEWIS 502-03551-02 AC Input/Output Module Product Features Analysis

GIDINGS&LEWIS 502-03551-02 AC input/output module is the core interaction unit for AC signal acquisition and driving in industrial automation systems. With seven core product features, it accurately adapts to the signal requirements of AC equipment, providing stable signal transmission and driving support for sensors, relays, AC motor drivers, etc., ensuring efficient operation of CNC machine tools, automated production lines, and other scenarios. The specific characteristics are analyzed as follows:

1、 Multi channel communication input and output: adapted to the collaborative needs of multiple devices

The module adopts a multi-channel AC input/output design, which can simultaneously process multiple AC signals, greatly improving the flexibility and efficiency of system control. At the input end, it supports 8-16 channels of AC signal acquisition (such as 220V/380V AC sensors, limit switch signals), and can synchronously receive equipment status signals from different workstations - for example, in an automated production line, the operating status of 12 AC motors can be collected through 12 input channels (such as motor overload protection switch signals); At the output end, it has 6-12 independent AC output channels, which can simultaneously drive relays, AC solenoid valves, small AC motors and other loads. For example, in packaging machinery, 8 output channels are used to control 8 AC loads such as feeding AC motors and cutting AC solenoid valves, without the need for additional modules, simplifying the system structure. Each channel is independently controllable and does not interfere with each other, meeting the industrial scenario requirements of multi device collaborative work and avoiding control group delays caused by insufficient channels.

2、 High precision signal processing: ensuring precise synchronization of equipment actions

The module has excellent high-precision AC signal processing capabilities, which can maintain high stability and accuracy in both signal acquisition and output, ensuring the precision and synchronization of industrial equipment actions. At the signal acquisition end, the accuracy error of AC voltage/current acquisition is ≤ 0.2% FS, which can accurately capture small signal changes of AC sensors (such as voltage fluctuations of AC pressure sensors), avoiding misjudgment of equipment status caused by acquisition errors; At the signal output end, the accuracy error of AC voltage output is ≤ 0.3% FS, and the stability of current output is ≤ 0.5%. For example, in a CNC machine tool, when outputting 380V AC voltage to the AC spindle driver, the voltage fluctuation is controlled within ± 1.14V to ensure stable spindle speed and avoid machining size deviation; In multi axis collaborative scenarios, precise AC signal output can achieve speed synchronization of multiple AC motors (such as warp and weft motors in textile machinery), ensuring process accuracy and reducing production waste caused by insufficient signal accuracy.

3、 High speed response: meeting the dynamic requirements of high-speed production

The module is equipped with an optimized AC signal processing circuit, which has fast input response and output driving capabilities, and can match the dynamic changes of high-speed production scenarios in real time. On the input side, the response time for collecting AC signals is ≤ 2ms,

2.产 品 展 示

3.其他产品

jetter JM-204-480-JC310-S1伺服驱动器

4.其他英文产品

ASEA 2668 180-291 slot control

| BA3628-7012-9-56BC | HG102A607 | 5751017-L DSTC456 ABB |

| BA3628-7012-9-48BP | HA48A6D521 | 5751017-A DST 452 ABB |

| BA3628-7012-1-56BC | HG105A6 | 57520001-DX/1 DSTC 406 ABB |

| BA3628-5822-9-56BC | HG92S94A6 | 57160001-AAA DSDI110A ABB |

| BA3628-1331-56B | HA110D6 | DSTC404 ABB |

| BA3624-7045-56C | SS9MS-11A1A0A | 5736 045-N DSMD113 ABB |

| BA3624-7024-9-56BC | HA42A6 | IMASO11 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218