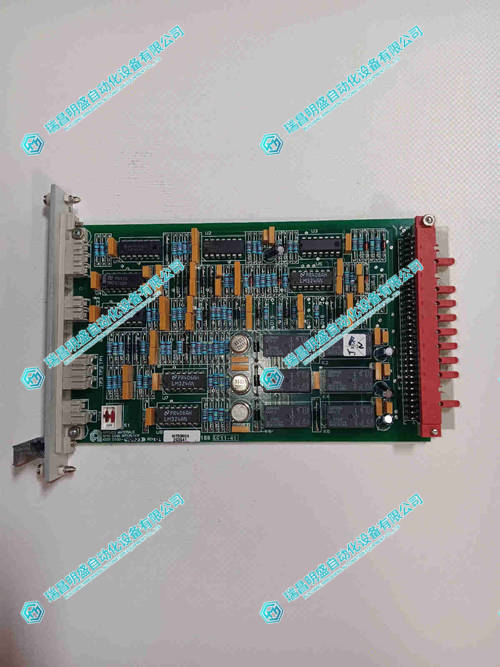

GIDINGS&LEWIS 502-03994-00数据采集模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 502-03994-00 数据采集模块产品特点解析

一、多通道数据采集:覆盖多源信号接入需求

二、高精度采集:保障数据可靠性与决策准确性

三、高速数据处理:适配高速场景实时性需求

英文资料:

GIDINGS&LEWIS 502-03994-00 Data Acquisition Module Product Features Analysis

The GIDINGS&LEWIS 502-03994-00 data acquisition module is the "core data acquisition unit" in industrial automation systems, responsible for the key functions of "multi-source signal access - precise measurement - real-time transmission". With seven core product features, it provides reliable raw data support for scenarios such as CNC machine tools and automated production lines, ensuring accurate decision-making and efficient operation of control systems. The specific characteristics are analyzed as follows:

1、 Multi channel data acquisition: covering multi-source signal access requirements

The module adopts a multi-channel design, which can simultaneously access and collect multiple different types of signals, perfectly adapting to the monitoring needs of multiple devices and parameters in industrial sites. On the one hand, it supports multiple digital signal inputs (usually 8-16 channels, depending on the configuration), and can be connected to photoelectric switches, travel switches, equipment status indicator lights, etc. to collect discrete status signals such as material arrival, equipment start stop, and fault alarms. For example, in an automated production line, it synchronously collects material detection signals from 6 workstations and operation status signals from 6 devices through 12 digital channels; On the other hand, it supports multiple analog signal inputs (usually 4-8 channels) and can be connected to temperature sensors (such as PT100 thermistor), pressure transmitters (4-20mA current signal), liquid level sensors (0-10V voltage signal), etc. to collect continuously changing physical parameters. The multi-channel parallel acquisition capability avoids the data delay caused by single channel one by one acquisition, greatly improves the efficiency of system data acquisition, reduces the number of modules, simplifies cabinet wiring and system structure.

2、 High precision acquisition: ensuring data reliability and decision-making accuracy

The module has excellent high-precision acquisition capabilities and can accurately measure key parameters such as voltage, current, and frequency, providing a reliable data foundation for control and monitoring systems and avoiding control errors caused by data deviations. In terms of analog data acquisition, the accuracy error of voltage acquisition is ≤ 0.1% FS, and the accuracy error of current acquisition is ≤ 0.05% FS. For example, when collecting 4-20mA signals from a pressure transmitter, the measurement error is ≤ 0.008mA, which can accurately reflect small changes in pressure inside the pipeline (such as pressure fluctuations of 0.1kPa); In terms of frequency acquisition, the measurement accuracy can reach ± 0.1Hz, which can accurately capture subtle changes in motor speed and pulse signal frequency (such as precise identification when the spindle speed fluctuates from 1500r/min to 1501r/min). In CNC machine tools, real-time detection of tool cutting load overload can be achieved by high-precision acquisition of spindle motor current signals; In chemical production, precise collection of reaction kettle temperature signals (error ≤ 0.1 ℃) ensures that the temperature control system can adjust the heating power in a timely manner, guaranteeing stable production processes and fully meeting the strict requirements for data accuracy in industrial scenarios.

2.产 品 展 示

3.其他产品

jetter JM-204-480-JC310-S1伺服驱动器

4.其他英文产品

ABB P8480 Analog Output Module

Radisys EPC-3307 processor board

| BA3614-4648-9-56BC | HZ40A60818 | EXM-17 |

| BA3608-1699-48B | H2-1522-1151 | 060-03644-0000 |

| AWC 500 | AMAT 0100-51017 | 44308902 |

| AMC 300 | AMAT 0100-90522 | 330878-90-00 |

| ALSTOM V4555724-0100 | AMAT 0100-76088 | 3500/22 146031-01 |

| AGL 400 | AMAT 0100-01714 | CE945GM2A-T25 |

| AGC-4 | AMAT 0100-38018 | GKWE001450R0009 XT382B-R9 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218