GIDINGS&LEWIS M.1017.6088 输入输出模块

1.产 品 资 料 介 绍:

一、产品概述

二、技术特性

英文资料:

1、 Product Overview

In the industrial automation layout constructed by the Giddings&Lewis PiC900 series control system, the M.1017.6088 input/output module occupies a pivotal position and can be regarded as a key "signal hub" for the system's interaction with the outside world. Its core mission is to efficiently achieve digital and analog signal interaction between controllers and field devices, which is the cornerstone of ensuring the smooth operation of the entire industrial automation system. On the one hand, it is like a sharp "sensing antenna", responsible for accurately collecting real-time data from various sensors and device status signals. Whether it is environmental temperature data feedback from temperature sensors or device position status transmitted by limit switches, it can be quickly captured by it; On the other hand, it also transforms into a powerful "control executor", accurately outputting control instructions generated by the controller to actuators or devices, driving motors to operate, controlling valve opening and closing, thereby achieving real-time monitoring and precise control of industrial automation systems, ensuring the orderly progress of production processes.

2、 Technical characteristics

Multi channel input/output, compatible with multiple signals: M.1017.6088 has powerful multi-channel input/output capabilities and can simultaneously support input/output operations for multiple digital and analog signals. In complex industrial production environments, there are various types of on-site equipment, and the types of signals generated are also diverse. For example, in large-scale chemical production facilities, there are both analog signals such as temperature, pressure, and flow rate, as well as digital signals such as equipment start stop and valve opening and closing. This module, with its multi-channel characteristics, can process these different types of signals in parallel, meeting the needs of large-scale and diversified industrial automation control, and providing comprehensive and accurate signal interaction support for the system.

Real time signal acquisition and high real-time guarantee: One of the significant advantages of M.1017.6088 is its ability to quickly respond to changes in the status of on-site equipment. During the operation of industrial automation systems, equipment status changes rapidly, and timely monitoring of these changes is crucial for ensuring stable system operation. Taking an automated production line as an example, when the product position sensor on the material conveyor belt detects that the product has reached a specific position, M.1017.6088 can capture this signal change in a very short time and quickly transmit it to the controller. This high real-time signal acquisition capability ensures that the control system can respond in a timely manner, adjust the equipment's operating status in real time, greatly improve the system's response speed and control accuracy, and ensure the efficient and stable production process.

Modular design, efficient collaborative work: M.1017.6088, which adopts the modular design concept, can be easily plugged into the PiC900 system rack to achieve seamless collaboration with CPU modules, servo drives, and other expansion modules. In the initial stage of system construction, engineers can flexibly select and combine various modules based on actual production needs to build the most suitable industrial automation control system architecture.

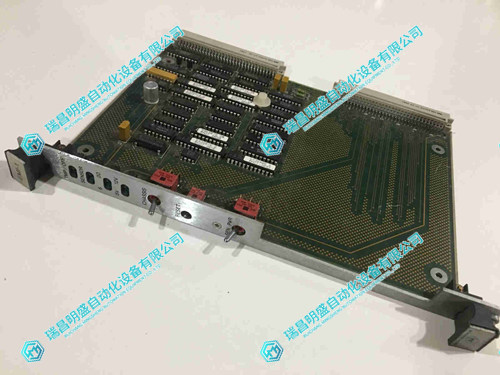

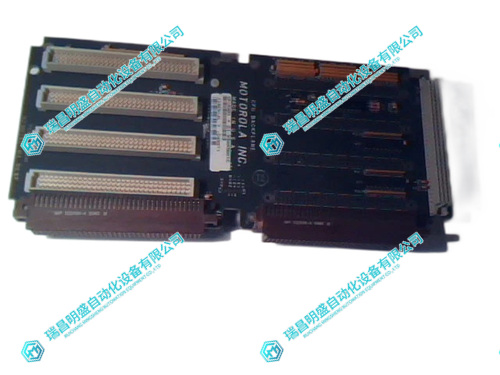

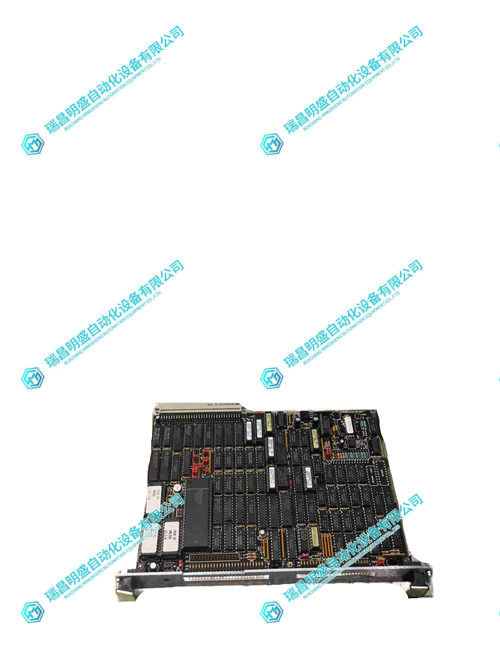

2.产 品 展 示

3.其他产品

4.其他英文产品

RADISYS 061-01450-0010 Network Adapter

Teknic SST-1500-XCX Digital Servo Drive

| 6ES5721-0CC00 | CACR-IRA5A5A5F | 061-01666-0010 |

| 6ES5721-0BF00 | CACR-SR44SZ1SDY231 | EMC-BP8-EMC-PS |

| 6ES5721-0BB00 | CACR-SR15BB1CSY8 | 61-0367-37 |

| 6ES5714-3CF00 | CACR-SR05BA1AM | 148472-006 |

| 6ES5714-3CB00 | CACR-SR15SZ1SSY228 | C2SBI-RSYS-JD1 |

| 6ES5712-8BF00 | CACR-HR10UB-Y9 | EMC-BP12 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218