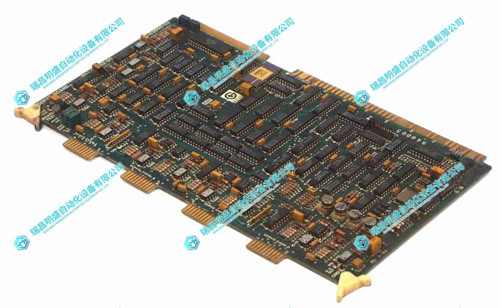

GIDINGS&LEWIS 502-03055-00伺服板

1.产 品 资 料 介 绍:

一、产品概述

二、产品特点

英文资料:

1、 Product Overview

In the PiC900 series control system built by Giddings&Lewis, the 502-03055-00 servo board can be regarded as the core hub of precision motion control. As a high-performance servo control unit, its main responsibility is to accurately drive and control servo motors, achieving closed-loop control of motor position, speed, and torque. In actual industrial automation systems, the servo board does not operate in isolation, but closely collaborates with the CPU, I/O modules, encoder, and driver. In the field of high-precision machine tools, it can ensure that the tool moves with micrometer level accuracy to complete precision machining of complex components; In industrial automation equipment, it can assist in the precise coordination of various mechanical components, achieve efficient and stable production, and provide solid guarantees for the high-precision operation of industrial automation.

2、 Product Features

High precision closed-loop control ensures precise and stable motion: The 502-03055-00 servo board adopts advanced control algorithms and technologies to monitor and adjust the position, speed, and torque of the servo motor in real time. In precision machining scenarios, such as optical lens polishing, precise control of the motor position ensures that the polishing tool adheres to the surface of the lens with an accuracy of micrometers, ensuring that the optical performance of the lens meets the standards; In high-speed operating equipment, the motor torque can be adjusted in real time to maintain stable speed, avoid speed fluctuations caused by load changes, and effectively improve motion accuracy and stability.

Multi axis control capability, achieving complex linkage: with powerful multi axis control function, it can simultaneously control multiple servo channels. In an automated production line with multi axis linkage, the actions of different motors can be coordinated to achieve precise material handling, positioning, and assembly. Taking the automotive parts assembly line as an example, this servo board can control multiple robotic arms to work together. Some are responsible for grabbing parts, while others are responsible for positioning and installation. Through precise multi axis linkage, assembly efficiency and quality are greatly improved, making it easy to meet complex industrial production needs.

High speed response, suitable for high-speed operations: The processing speed of control instructions and feedback signals is extremely fast. When receiving control instructions from the CPU or real-time motor status signals feedback from the encoder, it can respond in a very short time. In high-speed machining centers, cutting tools need to be frequently and quickly started, stopped, and reversed. The 502-03055-00 servo board can quickly adjust the motor operation to ensure accurate and timely tool movements, adapting to the fast-paced demands of high-speed machining and industrial operations, greatly improving production efficiency.

Modular design for convenient system operation and maintenance: Adopting the modular design concept, it can be easily plugged into the PiC900 system rack. In the initial stage of system construction, engineers can flexibly select modules based on actual needs and quickly build control systems; If additional functions are needed in the later stage, such as increasing the number of servo motor controls, corresponding modules can be directly added without the need for rewiring and large-scale debugging. When a module malfunctions, technicians can quickly locate and replace it, effectively reducing equipment downtime, lowering maintenance costs, and providing strong support for the continuity of industrial production.

2.产 品 展 示

3.其他产品

4.其他英文产品

HONEYWELL TK-FTEB01 51309512-175 Bridge

RADISYS 61-0159-03 CPU circuit board

RADISYS 61-0158-04 CPU Control Card

| 6ES5312-5CA12 | 6SC9711-0AL0 | 6DD2920-0XB01 |

| 6ES5312-5AA31 | CACR-PR01KA4BU | 6ES5187-5UA11 |

| 6ES5311-3KA11 | 6SC6030-2AA02 | 6DD2920-0WB00 |

| 6ES5308-3UA12 | 6SC9711-0AB0 | 6ES5155-3UA11 |

| 6ES5306-7LA11 | CACR-IR151515F | 6DD2920-0BF0 |

| 6ES5305-7LA11 | CACR-HR03BBY75 | 6ES5451-4UA13 |

| 6ES5301-3AB13 | 6SC9830-0AB20 | 6DD2920-0BE0 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218