GIDINGS&LEWIS HSM490伺服电机

1.产 品 资 料 介 绍:

一、产品概述

二、产品应用领域

英文资料:

1、 Product Overview

GIDINGS&LEWIS HSM490 is a high-performance industrial servo motor designed specifically for precision motion control systems. In the complex system of industrial automation, it does not operate in isolation, but works closely with controllers, servo drives, and encoders to build an efficient and accurate closed-loop control network. With advanced technology and precise manufacturing processes, the HSM490 is capable of high-speed and high-precision closed-loop control of position, speed, and torque. This outstanding performance makes it an ideal choice for complex industrial automation applications. Whether it is processing scenarios that require high precision or automated production lines that require high collaborative work, it can handle them excellently, providing solid power support for efficient and precise operation of industrial production.

2、 Product application areas

In the field of CNC machine tools, the HSM490 servo motor plays a crucial role. It undertakes the key task of driving the spindle and feed axis. In the precision machining process of parts, by precisely controlling the spindle, it ensures the stability and accuracy of the tool during high-speed rotation, achieves high-precision cutting, and meets the strict requirements of surface roughness and dimensional accuracy of the parts. At the same time, in multi axis linkage scenarios, it can accurately coordinate the motion of each axis motor. For example, when processing complex components such as aircraft engine blades, multiple coordinate axes can work together, and the tool can accurately cut along complex spatial curve trajectories, greatly improving processing efficiency and ensuring that the parts achieve micrometer level accuracy, helping the CNC machine tool industry move towards higher processing levels.

In the field of automated production lines, HSM490 is the core power source for achieving efficient and precise industrial actions. It can drive the handling device to grab and transfer materials at extremely high speed and accuracy, and quickly and accurately transport small components to designated assembly positions in the 3C product production line; In the assembly process, precise control of the assembly machinery's movements ensures the assembly accuracy of components and improves product yield; In terms of sorting devices, products of different specifications can be quickly sorted according to preset programs. More importantly, it can coordinate multiple devices to work synchronously, ensuring the smoothness and efficiency of the entire production line by operating in coordination with the motors of other devices, greatly improving the automation level of the production line.

In the field of industrial robots and robotic arms, the HSM490 servo motor is a key component for achieving flexible and precise movements. In the implementation of multi joint movements of the robotic arm, it can accurately control the motors at each joint, enabling the various joints of the robotic arm to coordinate and complete complex motion combinations. For example, in automotive parts welding operations, the robotic arm can accurately position the welding position according to a pre planned path, achieving high-quality welding. In terms of robot claw operation, the gripping force and position of the claw can be precisely controlled to achieve stable gripping and handling of objects of different shapes and weights; In precision operation scenarios, such as the installation of electronic chips, high precision operation can be ensured, expanding the application scope and operational capabilities of industrial robots and robotic arms in multiple fields.

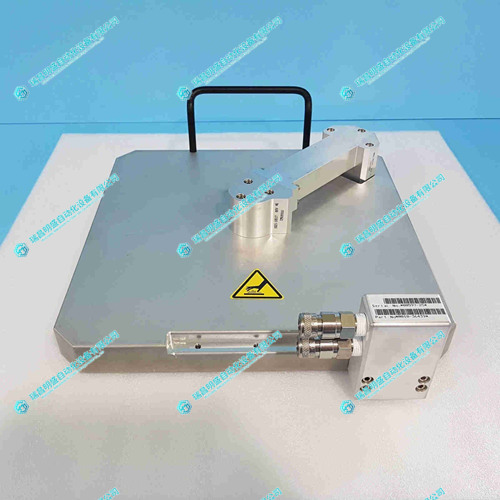

2.产 品 展 示

3.其他产品

4.其他英文产品

ABB UN0821B-P redundant output module

ASEA YB161102-AK Robot Computer Board

| 6ES5242-5AB21 | 6SC6506-0AA02 | PCD235A101 |

| 6ES5242-1AA32 | CACR-IR10SB | UNITROL 1010 |

| 6ES5241-1AD12 | 6SC6111-5DA00 | TRICONEX 3005 |

| 6ES5240-5AA31 | 6SC6500-0NA44 | SSA-G1018-0652 |

| 6ES5240-1AA21 | CACR-UP6AAA | TRICONEX 3721 |

| 6ES5188-3UH41 | CACR-TM333Z1SPY8 | PPE091A101 |

| 6ES5188-3UA12 | CACR-SR02BE12G-E | UAD206A101 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218