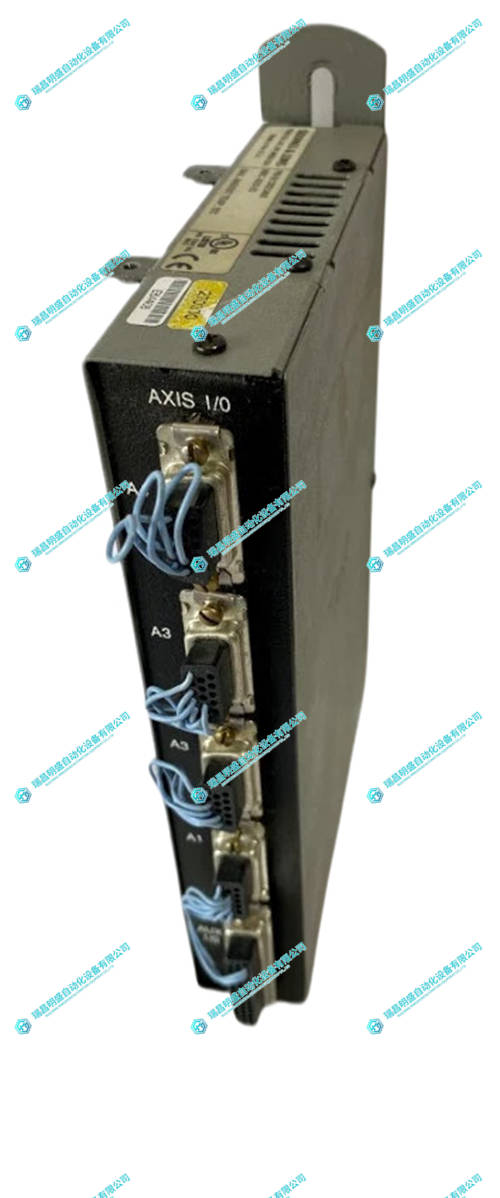

GIDINGS&LEWIS M.1302.5408输入输出模块

1.产 品 资 料 介 绍:

一、产品概述

二、技术特点

三、结构与安装

四、应用领域

英文资料:

1、 Product Overview

GIDINGS&LEWIS M.1302.5408 is a module that integrates digital input and output functions. Its core function is to build a signal exchange bridge between controllers and field devices in industrial automation systems. It can simultaneously process multiple input and output signals, complete on-site state acquisition, and issue execution commands to achieve logical control. It is a key connecting component in industrial control processes.

2、 Technical features

Bidirectional signal processing: The input supports multi-channel digital data acquisition and can be connected to signals from devices such as switches, sensors, and limit switches; The output terminal provides multiple digital drivers, which can control actuators such as relays, solenoid valves, and indicator lights.

Standard voltage adaptation: Adopting a 24VDC voltage level, it complies with the general standards in the field of industrial automation and can be directly compatible with most field devices without the need for additional voltage conversion.

Isolation and anti-interference design: Both input and output channels are isolated from the system bus, effectively reducing electrical noise interference in industrial sites and improving system operation stability.

Visual status monitoring: equipped with LED status indicator lights, which can intuitively display the signal status of each channel, facilitating on-site debugging and rapid fault location.

Security protection mechanism: Built in overcurrent and short-circuit protection functions to prevent module damage due to abnormal load and ensure reliable system operation.

3、 Structure and Installation

Modular adaptation: Adopting standardized design, it can be directly installed on G&L control racks or compatible I/O slots, facilitating system integration and expansion.

Convenient wiring: Supports screw terminal or plug-in terminal wiring, with simple operation, ensuring firm wiring and improving installation and maintenance efficiency.

Industrial grade durability: The shell and internal structure meet the requirements of industrial environments, can withstand high-intensity working conditions, and are suitable for long-term continuous operation.

4、 Application Fields

Numerical Control Machine Tool: Control fixture clamping/loosening, hydraulic valve action, cooling pump start/stop, and collect limit switch signals to ensure machining safety and accuracy.

Automated production line: Implement logical control in the assembly, handling, and testing stages, coordinate the actions of various equipment, and ensure a coherent and efficient production process.

Robot system: receives input signals such as workpiece positioning, emergency stop, and position feedback, outputs control commands such as fixture opening and closing, and auxiliary equipment start and stop, and cooperates with the robot to complete tasks.

Packaging and printing machinery: Control the feeding mechanism, cutting device, tension adjustment components, and equipment start stop to ensure production accuracy and rhythm.

Logistics and warehousing equipment: Collect signals from cargo detection sensors, issue instructions for conveyor belt operation, stacker crane operation, sorting device switching, etc., to improve logistics turnover efficiency.

2.产 品 展 示

3.其他产品

4.其他英文产品

REXROTH PPC-R22.1N-T-NN-P1-NN-FW servo

DELTA TAU ACC-24E2 interface simulation

ALSTOM 3EST125-975 DCC2382A Control Pane

| 296PLUS-DO-100P-120 | SA602-001-01 | IC3600SVZD1 |

| 281-600678 | S60100-NA | IC3600SVZC1 |

| 281-600243-1 | 52010-60 | IC3600SVZB1 |

| 281-600233-3 | PS-3306I-E-C104 | IC3600SVZA1C |

| 281-600120 | SM602-001 | IC3600SVZA1 |

| 281-500198-3 | PRD-P303250D-35 | IC3600SVSE1H1D |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218