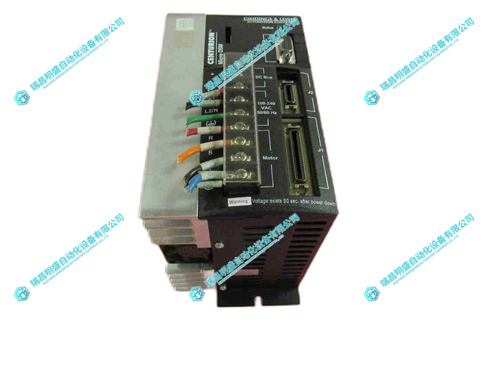

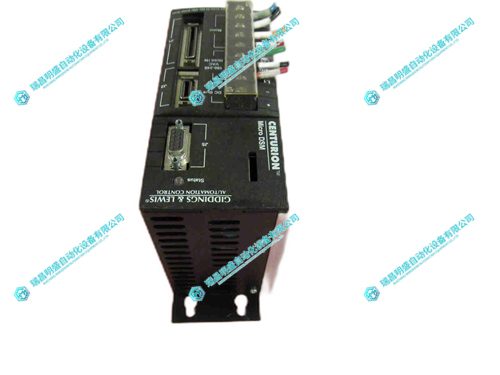

GIDINGS&LEWIS DSM-030交流伺服驱动器

1.产 品 资 料 介 绍:

一、产品概述

二、技术特点

英文资料:

1、 Product Overview

DSM-030 is an AC servo drive designed by Giddings&Lewis series specifically for small and medium power scenarios, focusing on the closed-loop control requirements of high-precision servo motors. Whether it is the feed axis drive of CNC machine tools, the lightweight actuator control of automated production lines, or the small joint drive of robots, it can accurately achieve speed, position, and torque regulation. With its stable motion control capability and fast command response, it is widely compatible with CNC machine tools, automated production lines, and robot systems, providing core power support for the efficient operation of small and medium-sized industrial equipment.

2、 Technical features

High performance closed-loop control: supports three core control modes: position loop, speed loop, and torque loop, and can be flexibly switched as needed. In the feed axis control of CNC machine tools, the position ring mode can accurately locate the tool movement trajectory, ensuring the machining accuracy of parts; In the scenario of conveyor belt drive in automated production lines, the speed loop mode can maintain a stable speed and avoid material transportation jamming; When the robot grabs lightweight workpieces, the torque loop mode can accurately control the output torque to prevent damage to the workpiece. The overall response speed is fast and the control accuracy is high. Even when facing complex motion trajectories such as frequent start stop and acceleration/deceleration, it can ensure smooth operation of the equipment.

Multiple feedback interfaces: compatible with incremental encoders, absolute encoders, and other industrial standard feedback devices, suitable for application scenarios with different accuracy requirements. When paired with an incremental encoder, it can provide real-time feedback on motor speed and angle changes, meeting conventional precision control requirements; When connecting the absolute encoder, there is no need to reset the device to zero after power failure and restart, and the absolute position of the motor can be directly obtained, greatly improving the efficiency of debugging and operation. By accurately collecting motor position and speed information, reliable data support is provided for closed-loop control, further ensuring the accuracy of equipment operation.

Comprehensive electrical protection: Built in five core protection functions including overcurrent, overvoltage, undervoltage, short circuit, and overtemperature, establishing a comprehensive safety protection system. When the motor load is too large and causes abnormal current, the overcurrent protection quickly cuts off the circuit; When the voltage fluctuation of the power grid exceeds the safe range, overvoltage/undervoltage protection is activated to avoid damage to the driver; When a short circuit fault occurs in the circuit, the short circuit protection responds immediately to reduce the impact of the fault; When the internal temperature of the drive is too high, the over temperature protection will pause and trigger an alarm, and restart after the temperature is restored. These protection functions not only enhance the safety of system operation, but also effectively extend the service life of the drive.

Modular compatibility: Adopting modular design, seamless compatibility with G&L series controllers and input/output modules is achieved. When integrating the system, there is no need for additional adaptation accessories, and it can be directly connected to the existing G&L control system, reducing the workload of wiring and debugging; When maintaining or upgrading in the later stage, it is sufficient to replace or add modules separately without changing the overall system architecture, which reduces maintenance costs. At the same time, it supports linkage with other industrial standard equipment to enhance the flexibility of system expansion and meet the customized needs of different production scenarios.

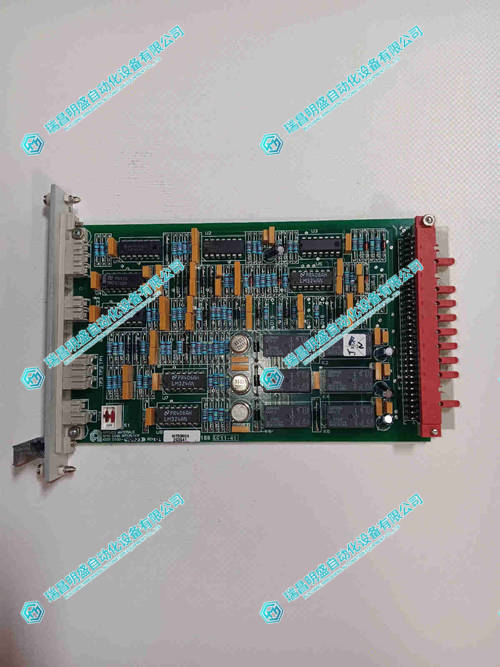

2.产 品 展 示

3.其他产品

jetter JM-204-480-JC310-S1伺服驱动器

4.其他英文产品

Emerson P144.R4 Intelligent I/O Board

ABB XVC768117 Field Input/Output Module

Eaton XV-440-10TVB-1-50 Touch Screen

| AMAT 0100-00054 | LTP-2323-2 | VE4003S2B6 |

| AMAT 0100-35207 | TP-7661-1 | SE4301T04 |

| AMAT 0100-00146 | TP-1693-4 | EI813F |

| AMAT 0100-35012 | MC256IV-C | AAI835-H50 |

| AMAT 0100-00347 | TP-1696-3 | ART.5801-SD100C |

| AMAT 0100-01066 | TP-1366-0 | XVC767AE102 3BHB007209R0' |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218