GIDINGS&LEWIS 503-17600-00涡轮处理器

1.产 品 资 料 介 绍:

Giddings & Lewis 503-17600-00 涡轮处理器介绍

一、产品概述

二、产品特点

(一)高速信号处理能力

英文资料:

Introduction to Giddings&Lewis 503-17600-00 Turbo Processor

1、 Product Overview

Giddings&Lewis 503-17600-00 Turbo Processor is a "high-speed signal processing and control core" module designed specifically for high-speed rotating machinery and CNC systems. Its core function focuses on real-time interaction of key data of rotating equipment: on the one hand, it accurately collects speed (such as instantaneous speed, average speed), position (such as absolute angle, relative displacement), and acceleration (such as angular acceleration, linear acceleration) signals of high-speed rotating equipment such as turbines and spindles; On the other hand, real-time analysis and computation of collected signals are carried out through a built-in high-performance computing unit, and the processing results are fed back to the control system to drive the actuator to adjust actions, achieving high-precision motion control and mechanical synchronization.

In precision machine tools and automation systems, the turbo processor is a key component that ensures high-speed and high-precision operation - whether it is high-speed cutting of CNC machine tools, linkage and coordination of multi axis equipment, or safety monitoring of turbo machinery, it relies on its fast signal processing capability and precise feedback control, providing core support for the efficient and precise operation of industrial equipment.

2、 Product Features

(1) High speed signal processing capability

Real time acquisition of high-speed signals: With ultra-high signal sampling frequency (usually up to MHz level), it can capture high-speed dynamic signals of turbines or rotating equipment in real time. For example, in scenarios where the spindle of a CNC machine tool rotates at high speeds (up to 10000rpm), thousands of pulse signals can be accurately collected per revolution, reflecting the instantaneous speed fluctuations and position changes of the spindle in real time, avoiding signal distortion caused by sampling delays, and providing accurate raw data for subsequent control decisions.

Multi axis data synchronization operation: supports synchronous acquisition and parallel operation of multi axis motion data, and can simultaneously process signals from multiple rotating devices (such as the spindle and multiple feed axes of multi axis CNC machine tools). By optimizing the synchronization algorithm, the time consistency of data collection for each axis is ensured, avoiding multi axis linkage errors caused by data delay. For example, in multi axis linkage machining, the speed and position data of each axis can be synchronously calculated, providing synchronous support for the interpolation operation of the controller, ensuring smooth and accurate multi axis motion trajectories, and meeting the requirements of high-speed and complex machining.

High responsiveness guarantee: With high-performance computing chips and streamlined signal processing flow, the delay time from signal acquisition to feedback is significantly reduced (usually up to microseconds). In high-speed dynamic scenarios (such as sudden acceleration, deceleration, or sudden load changes of rotating equipment), it can quickly respond to signal changes, adjust output control instructions in a timely manner, avoid equipment out of step or control deviation caused by response lag, and ensure the stability and accuracy of the system during high-speed operation.

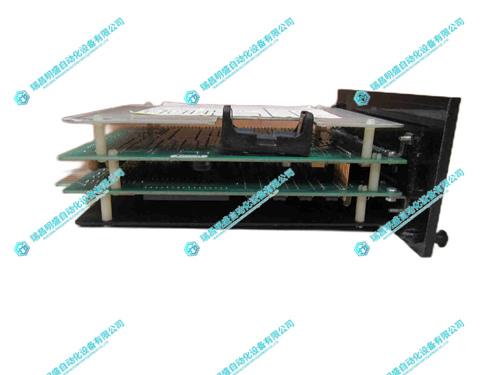

2.产 品 展 示

3.其他产品

4.其他英文产品

Radisys ATCA-PP81 controller module

AMAT 0190-24282 encoder module

IC3600EPSS1B power supply boar

| R67GENA-R2-NS-VS-00 | CACR-SR09TZ6SM | EXP-VID-B |

| R67GENA-R2-NS-NV-00 | CACR-IR050505F | 11901 |

| R67BENH-R2-NS-NV-00 | CACR-HR20UB-Y9 | 61-0154-22 |

| R67BEAH-R2-NS-NV-00 | CACR-PR30BC3AFY134 | 61-0475-14 |

| R65HENA-TS-NS-NV-00 | CACR-SR15SB1AFY100 | EPC-27 |

| R65HENA-TS-MZ-NV-00 | CACR-PR30BC3CSY166C | 61-0539-10 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218