GIDINGS&LEWIS M.1301.9806热电偶

1.产 品 资 料 介 绍:

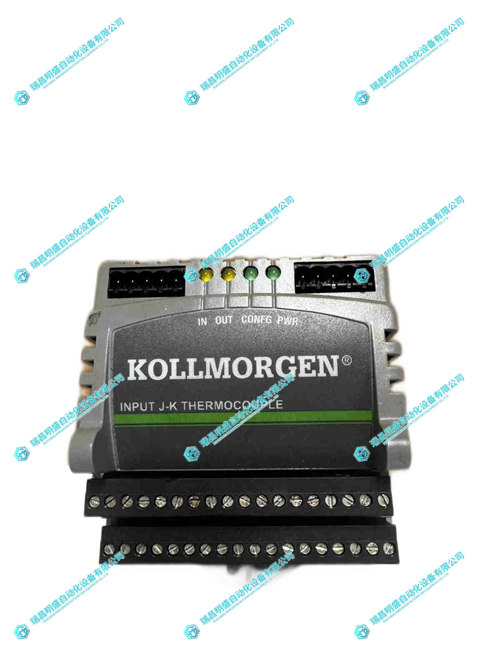

Giddings & Lewis M.1301.9806 热电偶输入模块介绍

一、产品概述

二、产品特点

(一)高精度温度采集

英文资料:

Introduction to Giddings&Lewis M.1301.9806 Thermocouple Input Module

1、 Product Overview

The Giddings&Lewis M.1301.9806 thermocouple input module is the core component of the PiC series control system for achieving "precise industrial temperature acquisition", and can be regarded as the "signal conversion expert" for temperature monitoring and control. Its core function focuses on the processing and conversion of thermocouple signals: on the one hand, it receives weak voltage signals (usually in the millivolt range, fluctuating with temperature changes) output by thermocouple sensors; On the other hand, through built-in signal amplification, cold end compensation, and analog-to-digital conversion circuits, weak voltage signals are accurately converted into standard digital signals (such as 4-20mA current signals or digital signals) that can be recognized by PiC controllers, providing precise data support for temperature monitoring and automatic control.

In high-precision machining equipment and industrial automation systems, this module is the key to ensuring stable temperature parameters - whether it is spindle temperature monitoring for CNC machine tools, equipment temperature control for automated production lines, or furnace temperature management for process systems, they all rely on their precise signal conversion capabilities, providing important guarantees for the safety, stability, and accuracy of industrial production.

2、 Product Features

(1) High precision temperature acquisition

Multi type thermocouple adaptation: The module has a wide range of thermocouple compatibility and supports various commonly used types of thermocouple inputs, such as K-type (nickel chromium nickel silicon, temperature range -270 ℃~1372 ℃), J-type (iron constantan, temperature range -210 ℃~1200 ℃), T-type (copper constantan, temperature range -270 ℃~400 ℃), etc. Different types of thermocouples correspond to different temperature measurement ranges and accuracy characteristics. Modules can be flexibly adapted according to the temperature measurement needs of industrial scenarios. For example, K-type thermocouples are suitable for high-temperature processing scenarios (such as machine tool spindles and industrial furnaces), while T-type thermocouples are suitable for low-temperature environments (such as refrigeration equipment and low-temperature reactions). They can meet diverse temperature measurement needs without replacing modules, reducing equipment selection and maintenance costs.

Cold end compensation ensures accuracy: Built in high-precision cold end compensation circuit effectively solves the core error source of thermocouple temperature measurement. The temperature measurement principle of thermocouples is based on the "voltage generated by the temperature difference between the hot end (measuring end) and the cold end (reference end)". If the temperature of the cold end fluctuates, it will directly lead to measurement errors. The module monitors the cold end temperature in real-time through a built-in temperature sensor, automatically calculates and compensates for errors caused by changes in cold end temperature, and controls the temperature measurement accuracy within ± 0.1 ℃~± 0.5 ℃ (depending on the type of thermocouple). For example, in CNC machine tool spindle temperature measurement, cold end compensation can avoid spindle temperature misjudgment caused by environmental temperature changes, ensuring that machining accuracy is not affected by temperature deviation.

2.产 品 展 示

3.其他产品

4.其他英文产品

IC3600EPSS1B power supply boar

| R67GENA-R2-NS-VS-00 | CACR-SR09TZ6SM | EXP-VID-B |

| R67GENA-R2-NS-NV-00 | CACR-IR050505F | 11901 |

| R67BENH-R2-NS-NV-00 | CACR-HR20UB-Y9 | 61-0154-22 |

| R67BEAH-R2-NS-NV-00 | CACR-PR30BC3AFY134 | 61-0475-14 |

| R65HENA-TS-NS-NV-00 | CACR-SR15SB1AFY100 | EPC-27 |

| R65HENA-TS-MZ-NV-00 | CACR-PR30BC3CSY166C | 61-0539-10 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218