GIDINGS&LEWIS 502-03423-01双服务器模块

1.产 品 资 料 介 绍:

数控机床控制系统

工业自动化生产线

过程控制与监测

英文资料:

The functionality and value of the GIDINGS&LEWIS 502-03423-01 dual server module highlight its critical role in various industries.

Numerical Control Machine Tool Control System

In the control system of CNC machine tools, the GIDINGS&LEWIS 502-03423-01 dual server module plays an irreplaceable role as one of the core modules of the CNC system. It can efficiently achieve multitasking parallel processing, while quickly processing complex instructions from CNC programming and monitoring the running status of various components of the machine tool in real time. During the machining process, this module relies on its powerful computing capabilities to quickly perform interpolation operations, accurately calculate the tool's motion trajectory, and ensure machining accuracy. At the same time, it can also have stable data interaction with the servo system, spindle system, etc. of the machine tool, ensuring that all components work together and greatly improving machining efficiency. Whether it is fast cutting of simple parts or precision machining of complex surfaces, it can handle them with ease.

Industrial automation production line

When applied to control centers for assembly lines, inspection lines, and packaging lines, the 502-03423-01 dual server module exhibits unique advantages. Its dual server redundancy structure is the key to ensuring production continuity and high reliability. On the assembly line, the server module precisely controls the movement of the robotic arm, enabling it to quickly and accurately grasp and install components, while monitoring various parameters in real-time during the assembly process. Once an abnormality occurs, the redundant server seamlessly takes over the work, avoiding production interruptions. The same applies to the testing and packaging lines, ensuring the accuracy of product testing and the efficiency of packaging, maintaining the stable operation of the production line, reducing downtime caused by failures, and providing solid support for enterprises to improve production efficiency.

Process Control and Monitoring

In continuous industries such as metallurgy, chemical engineering, and papermaking, there should be no errors in the production process. The GIDINGS&LEWIS 502-03423-01 dual server module is responsible for core data processing and process management. It collects various key data such as temperature, pressure, and flow rate in real-time during the production process, performs rapid analysis and processing, and provides a basis for production decision-making. In the event of equipment failure or process abnormalities, it is possible to quickly perform fault switching, activate redundant servers, ensure data is not lost, and production is not interrupted. And through data redundancy technology, important data is backed up and stored to prevent data loss due to hardware damage and other reasons, effectively ensuring the stability and continuity of the production process.

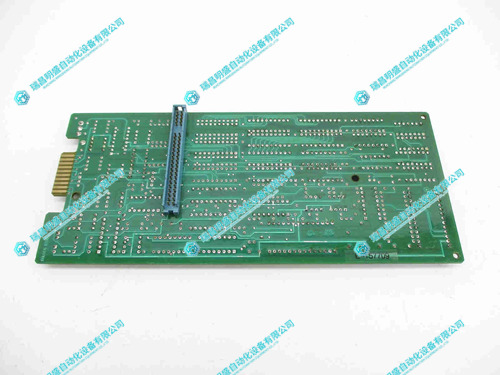

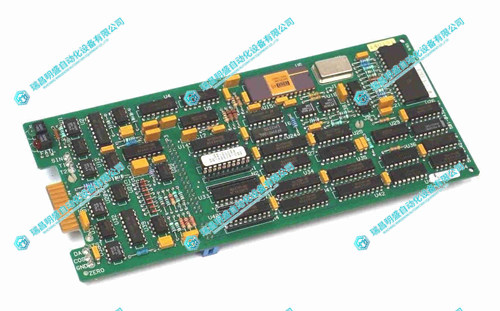

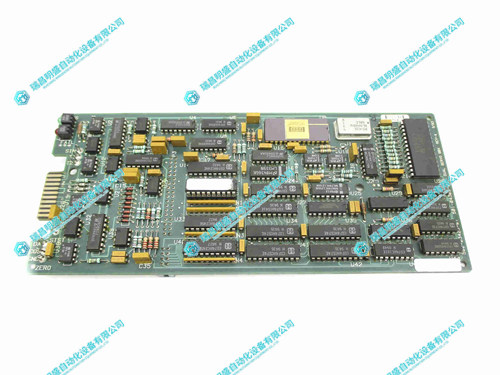

2.产 品 展 示

3.其他产品

INDRAMAT TDM1.3-050-300-W1-000 驱动模块

4.其他英文产品

HE700GEN200 Network Interface Module

ABB UN0503a-P Digital Output Module

| PMB31B-10100-01 | AMAT 0100-00015 | N41HRFL-LNK-NS-00 |

| PMB31B-10100-00 | AMAT 0100-14010 | 57160001-ACX DSDP 140B |

| PMB31B-00216-03 | IMFCS01 | P22NRXA-LDN-HD-00 |

| PMB31B-00216-02 | ICSM06A6 | P21NRXA-LSS-NS-00 |

| PMB31B-00216-01 | NKMF02-02 | PXUB201 |

| PMB31B-00216-00 | AMAT 0100-09210 | 57160001-UNC DSTD 150B |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218