GIDINGS&LEWIS 30005100 数字输入模块

1.产 品 资 料 介 绍:

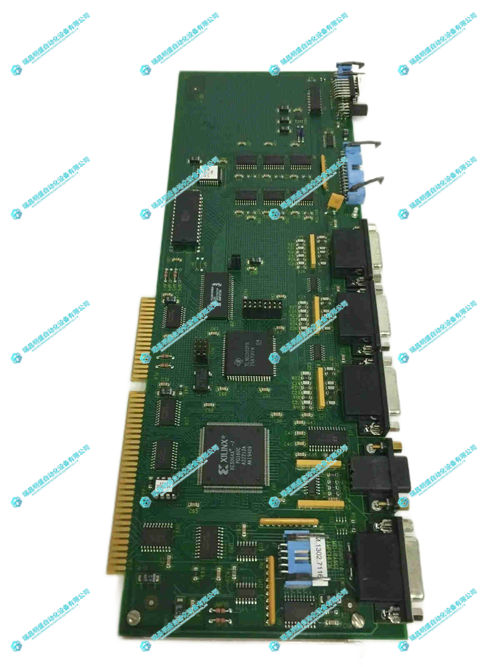

GIDDINGS & LEWIS 30005100 数字输入模块介绍

产品概述

产品特点

产品应用领域

英文资料:

Introduction to GIDINGS&LEWIS 30005100 Digital Input Module

Product Overview

The GIDINGS&LEWIS 30005100 digital input module, as an industrial grade I/O module, plays a key role in the acquisition and processing of controller digital signals in CNC machine tools, automated production lines, and other industrial control systems. It can reliably receive digital signal inputs from sensors, switches, and other sources, accurately transmit them to the control system, achieve precise control of equipment actions and real-time monitoring of status, and is an indispensable part of the industrial automation control process.

Product Features

Multi channel input: Supports simultaneous input of multiple digital signals, enabling centralized and efficient collection of external device status, meeting the needs of complex industrial systems for multi-source signal aggregation and processing.

High reliability: Adopting industrial grade design, it has excellent vibration resistance and can work stably even in environments where strong vibrations are generated during equipment operation; Strong anti-interference ability, can effectively resist complex electromagnetic interference in industrial sites, and ensure stable signal transmission.

Fast response: With low latency input signal acquisition characteristics, it can quickly capture signal changes, especially suitable for high-speed production and motion control scenarios, ensuring that the equipment responds quickly to control instructions.

High safety: Built in overcurrent protection, when the current rises abnormally, the circuit can be cut off in a timely manner to prevent damage to the module and connected equipment; Electrical isolation design separates modules from external circuits to avoid electrical interference and fault conduction, ensuring the safety of control systems and equipment.

Strong compatibility: can seamlessly integrate with GIDINGS&LEWIS series controllers, drivers, and output modules, and work together; Simultaneously supporting standard industrial interfaces, facilitating system expansion and upgrading, and adapting to industrial automation projects of different scales.

Modular structure: adopting a plug-in card design, easy installation, and quick insertion and replacement during maintenance; Beneficial for system expansion, the number of modules can be flexibly increased according to actual needs to enhance system functionality.

Product application areas

Numerical Control Machine Tool: Collecting spindle, feed axis, tool and sensor status signals to provide accurate data for the control system, helping to achieve precise machining control, and ensuring the accuracy and quality of component machining.

Automated production line: Receive status signals from conveying, assembly, testing, and packaging equipment, coordinate the actions of each process based on the signals, achieve automated operations, and improve the efficiency and coordination of production line operation.

Industrial robots: provide digital input interfaces for robot controllers, provide real-time feedback on the status of robot joints or linear modules, achieve multi axis motion monitoring and precise control, and ensure that robots complete complex tasks.

Process control industry: widely used in production processes such as chemical, metallurgical, and papermaking, collecting various digital signals, monitoring equipment operation status, and ensuring stable and efficient production processes.

Logistics and Warehouse Automation: Collecting status signals of sorting machines, stackers, and conveyor systems, synchronizing equipment actions based on signals, achieving intelligent scheduling, and improving the level and operational efficiency of logistics and warehouse automation.

2.产 品 展 示

3.其他产品

jetter JM-204-480-JC310-S1伺服驱动器

4.其他英文产品

KEBA D1420F F-SIC-1 Circuit Board

KEBA DO-321 Analog Output Module

| K32HCHJ-LNK-NS-00 | SS2000MD4-M | IMCPM01 |

| K32HCHJ-LEK-PF-01 | P50-001 | IEPAS01 |

| K32HCHJ-LEK-M2-01 | 6SC6101-3A-Z | IMASI23 |

| K32HCHJ-LEK-M2-00 | 02-052474-00 | IMASI13 |

| K31SSFS-LEK-SS-02 | IPFLD24 | |

| K31HRLG-LDK-NS-00 | 6SC6508-4AA02 | IMSED01 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218