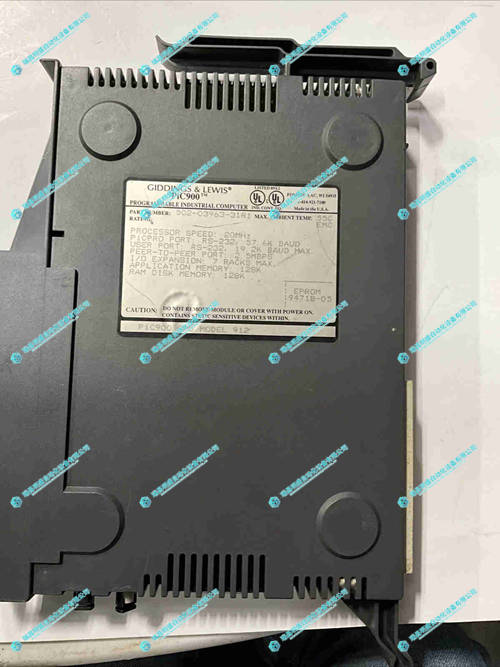

GIDINGS&LEWIS 502-03963-31输入输出模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 502-03963-31 输入输出模块介绍

一、产品概述

二、产品特点

英文资料:

Introduction to GIDINGS&LEWIS 502-03963-31 Input/Output Modules

In the complex network of industrial control systems, the GIDINGS&LEWIS 502-03963-31 input/output module is a key bridge connecting real production equipment with the control system center. It shoulders the responsibility of input signal acquisition and output command transmission, laying a solid foundation for reliable control and precise state monitoring of automation systems.

1、 Product Overview

502-03963-31, as an input/output module in the Giddings&Lewis system, is a key node for the smooth operation of industrial automation processes. It is closely connected to various input devices on site at one end, such as sensors that monitor temperature and pressure, limit switches that provide feedback on device position and status, etc. The signals generated by these devices are collected in real time and transmitted to the controller, allowing the control system to timely perceive the operation status of the on-site equipment. On the other end, it is connected to output devices such as actuators that control the start and stop of motors, relays that switch circuits, etc., accurately transmitting instructions issued by the controller to these devices and driving them to perform corresponding actions. For example, on an automated assembly line, it collects signals from material sensors and outputs control signals to the conveyor motor to ensure accurate and efficient material flow, which is one of the core components to ensure the normal operation of industrial automation systems.

2、 Product Features

Multi channel input and output: With powerful signal management capabilities, it supports multiple digital/analog inputs and outputs. In large-scale industrial projects, facing a large number of scattered on-site equipment, it can collect signals from numerous sensors and switches in a centralized manner, and output control instructions to multiple actuators and relays, greatly simplifying wiring complexity, improving system integration, facilitating centralized management of on-site equipment signals, and ensuring the orderly operation of the entire industrial control system.

Signal isolation design: Strict isolation measures are adopted between the input and output circuits as well as the control system. This design is like putting a layer of protective armor on the system, which can effectively resist the invasion of external interference signals. In industrial production sites, there are a large number of complex electromagnetic interferences, such as electromagnetic radiation generated by motor operation, strong electromagnetic pulses during welding machine operation, etc. Signal isolation design can avoid these interferences from affecting the accuracy and stability of input and output signals, improve the anti-interference ability of the system, ensure stable operation of the system, and reduce equipment misoperation or failure caused by signal interference.

High speed response: With excellent real-time processing capabilities, it can collect input signals at extremely fast speeds and quickly transmit output signals to corresponding devices. In industrial scenarios that require extremely high real-time performance, such as CNC machining processes, small changes in tool position need to be immediately fed back and adjusted. The 502-03963-31 module can capture the position signal from the sensor in a very short time, and after rapid processing, output the adjustment command to the motor drive device to ensure that the tool can respond in a timely and accurate manner, effectively avoiding machining errors or equipment damage caused by response delays,

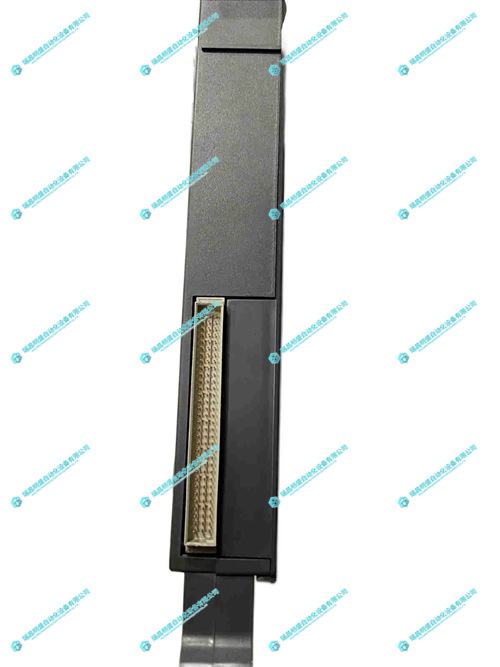

2.产 品 展 示

3.其他产品

Siemens 6ES7307-1EA01-0AA0 电源模块

4.其他英文产品

Asea 2668 170-3 Pcb Circuit Board

ASEA SNAT7600 driver control circuit board

ABB 3DDE300417 Input/Output Board

| 169PLUS-100P-240 | PA206Q-133 | F31X121PCRAEG1 |

| 169PLUS-100P-120 | PA200V-135 | 500-22560-000 |

| 169PLUS-100N-125VDC | PA200V-133 | 710-658041-00 |

| 169-120N-120 | PA15T-133 | 073-650069-00 |

| 169-10C-120 | PA10T-133 | 710-613108-001 |

| 169-100P-120 | PA08T-133 | 750-400159-00 |

| 1667607-00 B | PA08S-133 | 073-655650-00 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218